FAW Российский впускной канал: Мастеринг 12 Критически важные компоненты для безупречного воздушного потока при холодном пуске

The FAW Российский впускной канал Система служит дыхательной линией безопасности для двигателя тяжелого самосвала CA3250P66K24L1TE5Z.. Создан для покорения жестоких реалий сибирской тундры., эта логическая сборка выходит за рамки простой конвейерной обработки; это сложная сеть термостойких полимеров, демпфирующие кронштейны, и механизмы уплотнения с высоким крутящим моментом. В этом руководстве анализируются 12 важнейшие компоненты FAW Российский впускной канал, анализируем, как они обеспечивают чистый воздушный поток в условиях ниже -40°C.

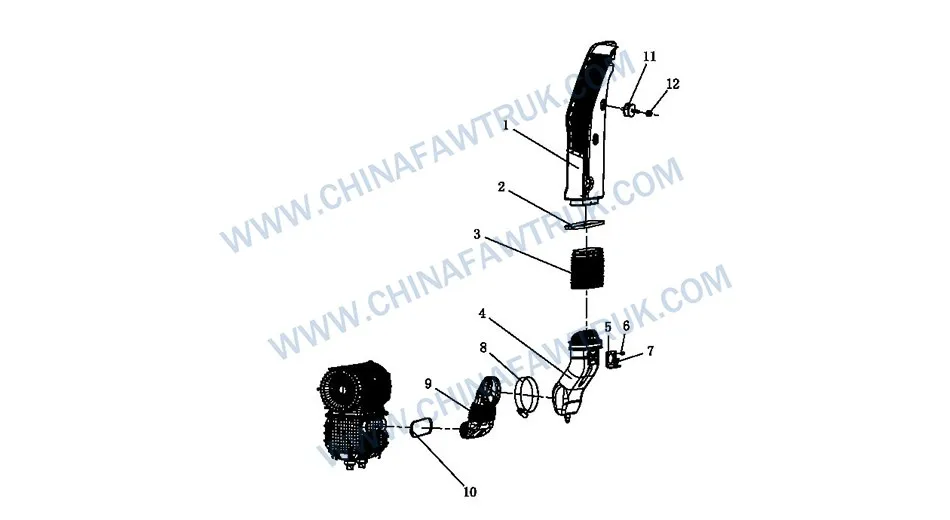

FAW Российский впускной канал

Динамика потока: Впускной канал в сборе

Основным каналом поступления воздуха в систему является Впускной канал в сборе (Шаблон) (Часть №. 1109230-61B-C00). Это не стандартная пластиковая трубка.; в контексте FAW Российский впускной канал система, это инженерный компонент, изготовленный из высококачественных армированных полимеров.. Дизайн должен примирить две противоположные силы.: высокий вакуум всасывания, создаваемый турбокомпрессором, и внешние силы воздействия льда и мусора. Внутренняя поверхность отполирована до микроскопического уровня, чтобы минимизировать сопротивление воздуха., обеспечение того, чтобы двигатель дышал свободно. Эта эффективность является основной характеристикой FAW Российский впускной канал архитектура, обеспечивая оптимальное сгорание даже при значительных колебаниях плотности воздуха во время зимней эксплуатации..

Подключение непосредственно к фильтрационной установке является Впускная труба – Воздушный фильтр (Шаблон) (Часть №. 1109291-74ты). Эта труба имеет особую геометрическую кривизну, предназначенную для ускорения воздушного потока и уменьшения турбулентности.. Турбулентность во впускном тракте может привести к ошибкам в показаниях датчиков и снижению эффективности сгорания.. Используя “Шаблон” дизайн, FAW гарантирует, что каждая заменяемая деталь сохраняет точный объемный КПД оригинальной детали. FAW Российский впускной канал заводская единица. В состав материала этой трубы входят УФ-стабилизаторы и пластификаторы, устойчивые к холоду., предотвращения “стеклопереход” фаза, когда полимеры становятся достаточно хрупкими, чтобы треснуть под действием простой вибрации двигателя..

Устранение зазора между жестким воздуховодом и воздухозаборником двигателя является Соединение шланговой сборки – Воздушный фильтр (Часть №. 1109260-50А). Этот гибкий компонент является невоспетым героем FAW Российский впускной канал сборка. Изготовлен из многослойной резины EPDM, армированной арамидными волокнами., он поглощает сильную тряску дизельного двигателя, изоляция жестких пластиковых воздуховодов от напряжений. В русские зимы, резиновые шланги меньшего размера замерзают до твердого состояния, передавать вибрацию до тех пор, пока что-нибудь не сломается. Этот специальный шланг FAW остается гибким даже при экстремально низких температурах., сохранение структурной целостности всей впускной линии.

Удержание давления: Логика зажима червячного привода

Система впуска хороша настолько, насколько хороши ее уплотнения.. The FAW Российский впускной канал использует избыточную стратегию зажима для предотвращения “вытирание пыли”— заглатывание нефильтрованного воздуха. Основным механизмом фиксации является Шланговый хомут с червячным приводом (Шаблон) (Часть №. 1109210-50А). В отличие от пружинных зажимов, которые со временем могут потерять натяжение., такая конструкция червячного привода позволяет добиться положительных результатов, затяжка с учетом крутящего момента. Лента из нержавеющей стали перфорирована для надежного сцепления с червячной передачей., обеспечение того, чтобы хомут не ослаблялся даже в условиях теплового расширения и сжатия работающего двигателя грузового автомобиля., жизненно важное требование для FAW Российский впускной канал надежность.

Для соединений большего диаметра, в системе используются Шланговый хомут с червячным приводом (Шаблон) (Часть №. 1109210-74ты). Дифференциация по размеру имеет решающее значение; использование хомута меньшего размера создает овальную форму шланга, приводящие к утечкам, в то время как слишком большой зажим оставляет “хвост” которые могут мешать работе других компонентов двигателя. Дополнением к ним являются специализированные Червячный привод шламного шланга тип B (Часть №. CQ676230B). The “Тип Б” обозначение относится к конструкции ленты с закругленными краями. Стандартные хомуты с острыми краями могут врезаться в мягкую резину EPDM шлангов при чрезмерном затягивании.. Зажим типа B предотвращает это повреждение., сохранение герметичности корпуса FAW Российский впускной канал система.

Стратегическое расположение этих зажимов внутри FAW Российский впускной канал архитектура создает надежный барьер против загрязнений. Это жизненно важно в пыльных условиях горнодобывающих предприятий.. Если зажим вышел из строя, абразивная кварцевая пыль попадает в цилиндры, действует как наждачная бумага на поршневые кольца. Поэтому, спецификация высокого класса, коррозионностойкая сталь для этих хомутов (серия CQ) это прямой ответ на засоленные дороги России, обеспечение работоспособности червячного механизма при техническом обслуживании даже после многих лет воздействия коррозионной слякоти.

Управление вибрацией: Кронштейны и основания

Система впуска занимает значительную длину по всему шасси., что делает его восприимчивым к гармоническому резонансу. Чтобы бороться с этим, а FAW Российский впускной канал сборка опирается на надежную сеть поддержки. The Соединение основания в сборе (Шаблон) (Часть №. 1109250-58ЧАС) действует как фундаментальный якорь. Этот компонент обеспечивает плоскую, устойчивая платформа для прокладки воздуховодов через моторный отсек. Его конструкция допускает небольшое боковое перемещение для обеспечения гибкости шасси., что характерно для самосвалов, передвигающихся по неровной местности., без передачи этого напряжения на пластиковые трубы FAW Российский впускной канал.

Выдерживать вертикальную нагрузку – это тяжелая работа. Скобка (Часть №. 1109311-43Б). Этот металлический кронштейн – больше, чем просто стойка.; его геометрическая форма препятствует усталостному растрескиванию. В русский холод, Усталость металла ускоряется. Инженеры FAW оптимизировали толщину и радиус изгиба этого кронштейна, чтобы он прослужил дольше автомобиля.. Он размещает воздуховоды вдали от источников сильного тепла, таких как выпускной коллектор., предотвращение термоциклирования и деформации пластика, таким образом поддерживая точное выравнивание, требуемое FAW Российский впускной канал.

Пожалуй, наиболее важным структурным компонентом является Демпфирующий кронштейн в сборе – Впускной канал (Часть №. 1109220-50А). Обратите внимание на количество: есть 5 из этих единиц, использованных при сборке. Это не жесткие крепления; они содержат резиновые изоляторы, которые изолируют воздуховод от частоты вибрации шасси.. Используя пять различных точек демпфирования, а FAW Российский впускной канал система эффективно “плавает” над двигателем. Это предотвращает превращение пластиковых воздуховодов в пыль из-за высокочастотного шума дизельного двигателя., распространенный вид отказа в конструкциях воздухозаборников плохой конструкции, где жесткое крепление приводит к немедленному разрушению.

Крепление целостности: Болты и контргайки

Для интеграции впускной системы требуются прочные крепежи.. The FAW Российский впускной канал использует Комбинированный болт (Часть №. CQ1461020) и Комбинированный болт (Часть №. CQ1461025). Эти “Комбинация” Болты имеют встроенные шайбы, которые крепятся к головке болта.. Такая конструкция ускоряет сборку на производственной линии, но, что еще более важно, гарантирует, что шайба никогда не будет забыта во время ремонта в полевых условиях. Шайба распределяет зажимную нагрузку., предотвращая раздавливание головкой болта пластиковых монтажных петель FAW Российский впускной канал компоненты.

Защита узла от постоянной вибрации 30-тонного грузовика – это Шестигранная фланцевая стопорная гайка (Часть №. CQ32606). Есть 5 этих орехов занято, соответствующие критическим точкам крепления. The “Блокировка” Особенность обычно включает нейлоновую вставку или деформированную резьбу, создающую трение., предотвращение откручивания гайки. В контексте FAW Российский впускной канал, Предпочтительны фланцевые гайки, поскольку широкий фланец действует как встроенная шайба., обеспечение большой площади поверхности для захвата. Это важно при креплении металлических кронштейнов к раме болтами..

Выбор этих специальных креплений подчеркивает внимание к деталям в CA3250P66K24L1TE5Z.. Стандартные болты ослабнут в течение первого 1000 километры дорог стиральной доски. Путем стандартизации высококачественного оборудования серии CQ, FAW гарантирует, что структурная целостность FAW Российский впускной канал система поддерживается. Любой компромисс в качестве оборудования нарушает логику всей сборки., потенциально может привести к ослаблению трубопроводов и катастрофическому повреждению двигателя на выходе.

Разбивка компонентов: 82. Логическая система впускного канала FAW Russian в сборе

| Нет. |

Номер детали |

Наименование |

Кол-во |

| 1 |

1109230-61B-C00 |

Впускной канал в сборе (Шаблон) |

1 |

| 2 |

1109210-50А |

Шланговый хомут с червячным приводом (Шаблон) |

1 |

| 3 |

1109260-50А |

Соединение шланговой сборки – Воздушный фильтр |

1 |

| 4 |

1109250-58ЧАС |

Соединение основания в сборе (Шаблон) |

1 |

| 5 |

1109311-43Б |

Скобка |

1 |

| 6 |

CQ1461020 |

Комбинированный болт |

4 |

| 7 |

CQ1461025 |

Комбинированный болт |

2 |

| 8 |

CQ676230B |

Червячный привод шламного шланга тип B |

1 |

| 9 |

1109291-74ты |

Впускная труба – Воздушный фильтр (Шаблон) |

1 |

| 10 |

1109210-74ты |

Шланговый хомут с червячным приводом (Шаблон) |

1 |

| 11 |

1109220-50А |

Демпфирующий кронштейн в сборе – Впускной канал |

5 |

| 12 |

CQ32606 |

Шестигранная фланцевая стопорная гайка |

5 |

Заключение: Логика арктической надежности

The FAW Российский впускной канал Система воплощает инженерную философию, лежащую в основе серии FAW J6P.: логика важнее простоты. В суровых условиях России, простая труба - это ответственность. За счет интеграции гибких демпфирующих кронштейнов, зажимы с закругленными краями, и химически стойкие полимеры, FAW создает систему впуска, которая одновременно достаточно жесткая, чтобы выдерживать турбонаддув, и достаточно гибкая, чтобы выдерживать кручение шасси.. Каждый компонент, от самого большого воздуховода до самой маленькой контргайки, играет жизненно важную роль в поддержании подачи чистого воздуха, от которого зависит работа двигателя., подчеркивая необходимость полного FAW Российский впускной канал упаковка.

Для владельцев автопарков, сообщение ясно: при обслуживании системы впуска, ярлыки не вариант. Использование обычных хомутов или неармированных шлангов нарушает тщательно сбалансированную логику сборки.. Только используя указанные оригинальные детали, можно гарантировать, что CA3250P66K24L1TE5Z продолжит работать с максимальной эффективностью., независимо от того, насколько низко опустится термометр. Инвестируйте в правильное FAW Российский впускной канал Компоненты – это инвестиции в долговечность и прибыльность всего автомобиля..

Упаковка и логистика

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..