Welcome to this essential analysis of the FAW J6P Condenser for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This is not just a radiator; it is the critical component that releases heat from the A/C system. This guide details the 2 key parts, the main assembly and its hardware, for a perfect service.

The FAW J6P Condenser is the A/C system’s “hot side,” mounted at the very front of the vehicle. Its sole function is to take the high-pressure, hot refrigerant gas from the compressor and turn it back into a high-pressure liquid. This phase-change process is what releases all the heat pulled from the cab into the outside air.

This teardown will analyze the main ‘Condenser with Receiver Drier Assy’ (8105010-70U). This is a modern, integrated design where the drier is attached directly to the condenser. We will explore the logic of this “parallel-flow” condenser and the critical role of the receiver drier.

For a technician, a blocked or leaking FAW J6P Condenser is a common cause of “no A/C” or “A/C blows warm.” Understanding its function and integrated components is key to a correct diagnosis, (e.g., distinguishing a condenser leak from a hose leak) and ensuring a full, proper system recharge.

This is the primary component of the FAW J6P Condenser system. It is a factory-assembled and sealed unit that combines two critical A/C components.

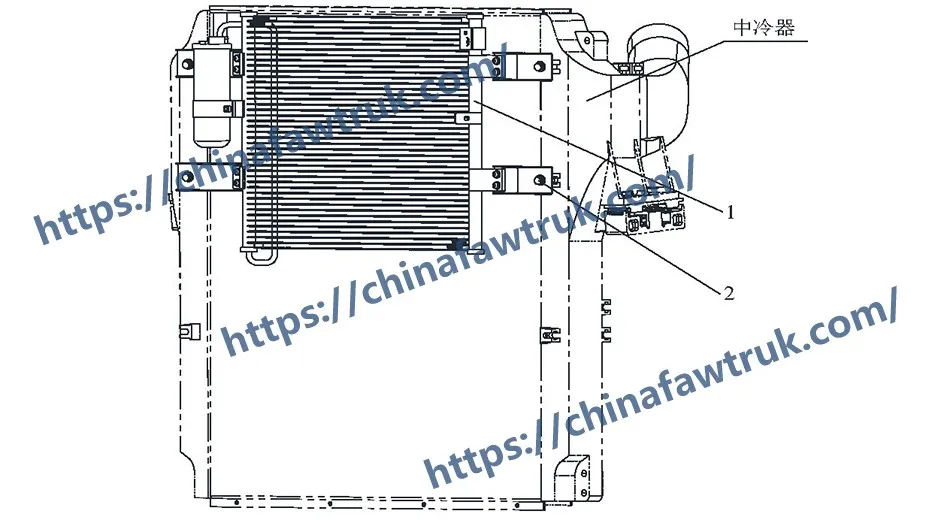

1. Component: ‘Condenser with Receiver Drier Assy’ (8105010-70U) – Qty 1

This (Mark 1) is the complete assembly. The ‘Assy’ is critical. It signifies that the condenser (the radiator part) and the receiver drier (the filter part) are supplied as a single, pre-connected, and quality-tested part.

The Integration Logic: This design is for efficiency and reliability. By integrating the receiver drier directly onto the side of the FAW J6P Condenser, the manufacturer eliminates a long, vulnerable refrigerant hose, several connection points, and a separate mounting bracket. This reduces potential leak points and simplifies assembly.

The Location Logic: The entire assembly is mounted at the very front of the truck’s cooling “stack,” typically in front of the radiator and the intercooler. This position is vital. It must receive the coldest, freshest airflow from the grille, driven by the truck’s forward motion and the main cooling fan, to work efficiently.

The “Cooling Stack” Logic: This “front-of-stack” position makes the FAW J6P Condenser the truck’s first line of defense. It is highly vulnerable to stone chips, rocks, mud, and insects. A condenser with fins that are clogged by mud or bent flat by a pressure washer will have its airflow blocked, leading to a catastrophic loss of A/C performance.

The Service Logic: This is a sealed unit. A leak in either the condenser core or the receiver drier housing necessitates the replacement of the *entire* 8105010-70U assembly. A technician cannot separate the drier from this specific FAW J6P Condenser. The system must be fully evacuated of refrigerant before unbolting this part.

This is the primary function of the FAW J6P Condenser. It is a high-efficiency radiator designed specifically for R134a refrigerant, not engine coolant.

The “Parallel-Flow” Logic: Modern condensers are “parallel-flow” (PF), not old “serpentine” tube-and-fin designs. A PF condenser uses multiple, flat, parallel tubes. This design is much lighter and more compact, but it dramatically increases the surface area and efficiency. It allows the hot gas to spread out, cool, and “condense” back into a liquid much faster.

The Fin Logic: Pressed between these flat tubes are thousands of paper-thin, “louvered” aluminum fins. These fins are the FAW J6P Condenser‘s primary heat-sink. They draw heat from the refrigerant in the tubes and transfer it to the air passing through them. The “louvers” (tiny angled cuts) create turbulence in the airflow, forcing the air to “scrub” against the fin, maximizing heat transfer.

The Material Logic: The entire condenser is made of brazed aluminum. This is for two reasons: 1. Aluminum is extremely lightweight. 2. It has a very high thermal conductivity, allowing it to transfer heat far more efficiently than steel.

The Failure Logic (Blockage): A failure of the A/C compressor can send metallic debris through the system, clogging the narrow tubes of the FAW J6P Condenser. A clogged condenser cannot be “flushed.” It must be replaced, along with the compressor and receiver drier.

This is the integrated “canister” attached to the side of the FAW J6P Condenser. It is the A/C system’s filter and water-trap.

The “Receiver” Logic: Its first job is to act as a temporary storage “receiver” for the liquid refrigerant. This ensures that the next component in the line (the expansion valve) is *always* fed a solid, bubble-free stream of liquid refrigerant, which is essential for proper A/C operation.

The “Drier” Logic: This is its most critical function. Inside the canister is a “desiccant” bag. This bag is filled with a material like silica gel, which has an extremely high affinity for water. Its job is to absorb and *permanently trap* any moisture (H2O) that has contaminated the refrigerant system.

The Moisture Control Logic: Water is the #1 enemy of an A/C system. It will mix with refrigerant to form corrosive acids, or freeze into ice and block the expansion valve. The drier in the FAW J6P Condenser prevents this.

The “Filter” Logic: The receiver drier also contains a fine-mesh filter. This filter traps any solid debris before it can reach and clog the tiny, precise expansion valve.

The Service Logic (Drier): The desiccant bag has a limited lifespan. It is *mandatory* to replace the drier (and in this case, the entire FAW J6P Condenser ‘Assy’) *every time* the A/C system is opened to the atmosphere (e.g., for a hose replacement). A new, dry drier is essential for a long-lasting repair.

This hardware is all that holds the lightweight but critical FAW J6P Condenser in place, securing it against the main radiator or its support frame.

1. Component: ‘Combination Bolt’ (CQ1460820) – Qty 4

This (Mark 2) is a set of four identical M8 bolts. They are the structural fasteners for the assembly.

The “Combination Bolt” Logic: The name “Combination Bolt” means each bolt has a pre-installed, captive washer. This is a vibration-resistance and assembly-speed feature. The washer (likely a spring lock washer and flat washer) prevents the bolt from backing out under the constant, high-frequency vibration of the diesel engine.

The Isolation Logic: These bolts do not mount the FAW J6P Condenser directly, hard-metal-to-hard-metal. They are almost always used with (unlisted) rubber bushings or grommets. These rubber isolators absorb vibration, preventing it from fatiguing the condenser’s delicate aluminum tubes and causing stress-cracks at the mounting brackets.

The Service Logic: A loose FAW J6P Condenser will vibrate, which will quickly lead to a stress-fracture leak at one of its welded joints. A technician must ensure these four bolts are present, properly torqued, and that any rubber isolation grommets are in good condition.

The following table provides the complete, detailed breakdown of all 2 component types specified for the FAW J6P Condenser system on the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 8105010-70U | Condenser with Receiver Drier Assy | 1 |

| 2 | CQ1460820 | Combination Bolt | 4 |

The specifications for the FAW J6P Condenser are defined by its integrated, high-efficiency design for the A/C system.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Condenser / A/C System |

| Primary Assembly | ‘Condenser with Receiver Drier Assy’ (8105010-70U) |

| Condenser Type | Parallel-Flow (PF) |

| Material | Brazed Aluminum (Tubes and Fins) |

| Integrated Component | Receiver Drier (Filter/Desiccant Bag) |

| Function 1 | Condenses high-pressure R134a gas to liquid |

| Function 2 | Removes moisture (water) from refrigerant |

| Function 3 | Filters debris from refrigerant |

| Mounting Hardware | ‘Combination Bolt’ (CQ1460820) |

| Hardware Quantity | 4 |

| Service Note | Must be replaced if A/C system is opened to atmosphere. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.