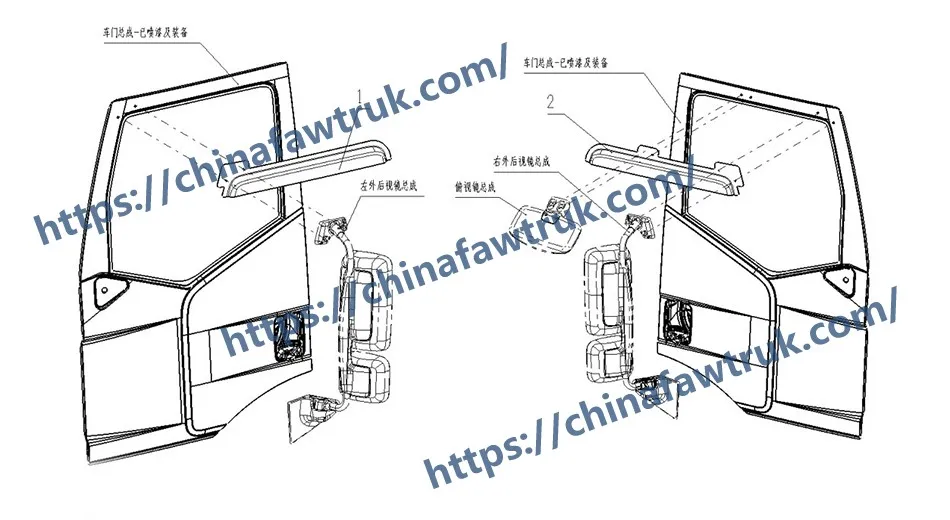

This is a technical deconstruction of the Front Door Rain Deflector, designed for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This component, also known as a window visor or vent shield, is a critical accessory. It enhances driver comfort and safety by managing airflow and blocking rain, allowing for window ventilation in all weather conditions.

The Front Door Rain Deflector (6101551BD04 / 6101552BD04) is more than just a piece of plastic; it is an aerodynamic tool. Its core logic is to create a high-pressure channel that physically pushes rain, sleet, and road spray away from the side window. This allows the driver to have the window partially open for fresh air, even during a storm, without getting wet. This guide will analyze this single component type in detail.

This first logic deconstructs the primary function of the Front Door Rain Deflector: how it manipulates air and water. This is the “why” of the component’s existence.

1. Component: ‘Left door rain deflector’ (6101551BD04) – Qty 1

2. Component: ‘Right door rain deflector’ (6101552BD04) – Qty 1

These components are the complete Front Door Rain Deflector units. Their primary function is aerodynamic.

The Aerodynamic Logic is key. The deflector is not a simple flat panel; it is a precisely shaped airfoil. This curve is engineered to catch the slipstream of air flowing over the A-pillar and the side mirror. It redirects this air, creating a high-velocity curtain that flows down and away from the side window glass.

This air curtain acts as a kinetic barrier. It has enough force to “push” falling raindrops, sleet, and even light snow away from the window opening. This is what allows the window to be open while it is raining.

The Ventilation Logic is directly enabled by this. The cab of a CA3250P66K2L1T1E truck, especially on a dusty construction site or in humid weather, can become hot and stuffy. The Front Door Rain Deflector allows the driver to crack the window open, typically 1-2 inches, for constant fresh air.

The deflector forms a physical “roof” over the opening, and the aerodynamic barrier prevents water from being sucked into the cab. This is vital for driver comfort and alertness.

This ventilation is also critical for defogging. It allows humid, warm air to escape, clearing the side windows and mirror view without requiring the air conditioning system to be on, which can save fuel.

A secondary benefit is Wind Noise Reduction. Driving at highway speeds with a window open creates loud, low-frequency “buffeting”. The Front Door Rain Deflector smooths the airflow entering the cab, breaking up this buffeting and significantly reducing the overall noise level for a more comfortable driver experience.

This logic analyzes the physical construction of the Front Door Rain Deflector. The material choice is critical for its longevity, safety, and performance.

1. Component: ‘Left door rain deflector’ (6101551BD04) – Qty 1

2. Component: ‘Right door rain deflector’ (6101552BD04) – Qty 1

The part numbers 6101551BD04 and 6101552BD04 are manufactured to withstand the harsh environment of a dump truck, which involves much more than just rain.

The Material Logic is based on durability. These deflectors are almost always made from high-impact, modified acrylic or a robust polycarbonate blend. This material is chosen for its superior combination of properties. It is tough enough to withstand impacts from small road debris, rock chips, and even the brushes of an automatic truck wash without cracking or shattering.

This impact resistance is a key safety and serviceability feature. A cheap, brittle plastic would fail quickly, creating a hazard. This high-grade polymer ensures the Front Door Rain Deflector can last for the life of the vehicle.

The UV Resistance Logic is paramount. A Front Door Rain Deflector is exposed to direct, harsh sunlight for its entire life. These components are impregnated with UV stabilizers. This chemical treatment prevents the polymer from breaking down under solar radiation.

This stops the “chalking” (a white, dusty surface), fading, and embrittlement that unprotected plastics suffer from. This ensures the deflector remains strong, flexible, and retains its color.

The Optical Logic relates to the finish. Most Front Door Rain Deflector units are produced in a “smoke” tint. This is a dark, semi-transparent finish. This tint helps to reduce glare from the sun when it is high in the sky, acting as a small, fixed sunshade for the driver’s peripheral vision. The material is still optically correct, meaning it does not distort the driver’s view when looking through it.

The final logic concerns how the Front Door Rain Deflector integrates with the vehicle. A perfect, secure fit is essential for it to function correctly and to prevent it from causing new problems, such as wind noise or damage.

1. Component: ‘Left door rain deflector’ (6101551BD04) – Qty 1

2. Component: ‘Right door rain deflector’ (6101552BD04) – Qty 1

The design of these parts is specific to the FAW Jiefang CA3250P66K2L1T1E. They are not universal-fit components, which is critical for their function.

The Installation Logic is designed for simplicity and reliability, with two primary methods. The first, and most common, is “in-channel”. The Front Door Rain Deflector has a thin, flanged edge that is inserted directly into the window glass channel, alongside the glass. It is held in place by the pressure of the channel’s felt or rubber seals. This is a clean, no-drill solution that looks very integrated.

The second method is “tape-on”. These deflectors come with pre-applied, high-strength automotive-grade adhesive tape (such as 3M VHB). This tape adheres to the painted surface of the door frame, just above the window. Both methods are designed to be permanent, secure, and vibration-free.

The Precision Fit Logic is critical. These parts are manufactured from a mold made specifically from the CA3250P66K2L1T1E’s door frame. This exact fit ensures that all curves match the body lines perfectly.

A poor, universal-style fit would create air gaps, leading to whistling noises at high speed, which would defeat the noise-reduction benefit. A bad fit could also interfere with the window’s operation, potentially triggering anti-pinch safety features or causing the glass to bind.

This precision ensures that the Front Door Rain Deflector does not interfere with the function of the side mirror and integrates seamlessly into the door’s existing design, appearing as an original equipment part.

The following table provides the complete, detailed breakdown of the single component type that constitutes the Front Door Rain Deflector assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 6101551BD04 | Left door rain deflector | 1 |

| 6101552BD04 | Right door rain deflector | 1 |

The specifications for the Front Door Rain Deflector are defined by its role as an aerodynamic accessory for driver comfort and all-weather ventilation.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Front Door Rain Deflector (Window Visor) |

| Associated System | Cab Door, Window Assembly, Weatherproofing |

| Primary Logic | Aerodynamic Rain & Spray Deflection |

| Secondary Logic | All-Weather Ventilation, Wind Noise Reduction |

| Core Component | ‘Left/Right door rain deflector’ (6101551BD04 / 6101552BD04) |

| Core Material | High-Impact, UV-Stabilized Acrylic or Polymer |

| Typical Finish | Tinted (Smoke) |

| Installation Type | In-Channel or High-Strength Adhesive Tape |

| Mount Location | Door Frame / Window Channel |

| Total Component Types | 1 (plus mirrored version) |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.