Welcome to this essential teardown for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. We are deconstructing the Front Door Insect Screen Assembly, a vital system for cabin integrity and driver comfort. This guide breaks down the 4 critical components, from the main frame to the essential weatherstrips, providing a complete functional analysis for technicians.

The function of this Front Door Insect Screen Assembly extends far beyond simple comfort. For the heavy-duty FAW Jiefang CA3250P66K2L1T1E, operating in environments ranging from dusty quarries to humid construction sites, this component is a frontline defense. It is engineered to protect the driver, maintain the cleanliness of cabin instrumentation, and reduce operational distractions.

This Front Door Insect Screen Assembly deconstruction analyzes the system by its core functions. We will investigate the structural design of the main assembly, the filtration technology of the mesh, and the crucial role of the associated sealing components. Understanding this logic is key to correct diagnosis, maintenance, and replacement, ensuring the cabin remains a safe and controlled environment.

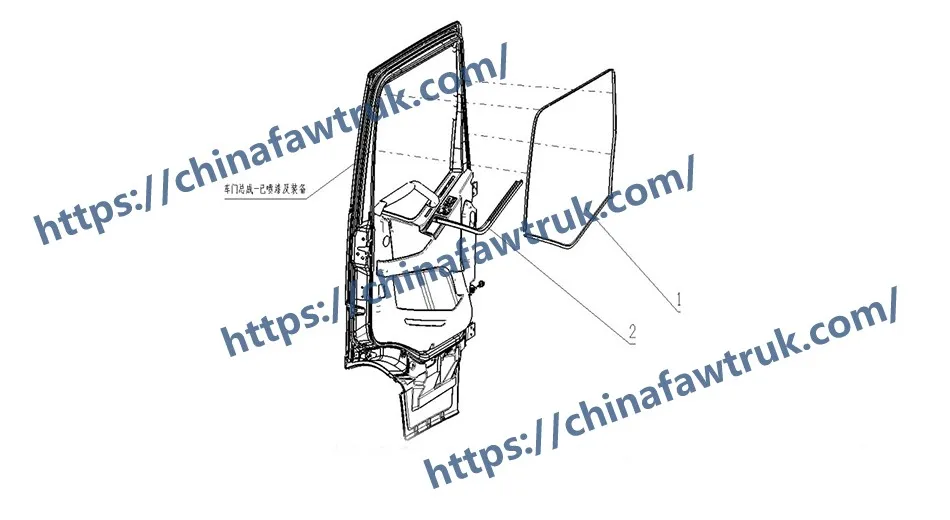

The foundation of the entire Front Door Insect Screen Assembly system is the structural frame. This is an engineered component designed for precise integration within the FAW truck’s door shell.

1. Component: ‘Left Front Door Insect Screen Assy’ (6103105BD04)

This component, marked as item 1 for the driver’s side, is the core of the Front Door Insect Screen Assembly. The designation Assy (Assembly) is critical. It confirms this is a complete, non-serviceable unit containing both the frame and the permanently affixed mesh.

2. Component: ‘Right Front Door Insect Screen Assy’ (6103110BD04)

This is the corresponding assembly for the passenger’s side (Item 1, Right). It is an integrated unit designed for a perfect fit and long-term durability, protecting the cabin from insects and debris.

The Frame Logic (Applies to both): The frame itself is precision-molded from a high-impact, UV-stabilized polymer. This material selection is a deliberate engineering choice to provide extreme rigidity and prevent rattling.

Unlike metal, this polymer composite is 100% corrosion-proof, essential for a vehicle exposed to road salt and moisture. The UV stabilization prevents solar radiation from degrading the polymer, which would otherwise lead to cracking.

The Mounting Logic: This Front Door Insect Screen Assembly frame is molded to the exact contours of the CA3250P66K2L1T1E door. It slides into a dedicated channel, separate from the main window glass, allowing the window to operate independently. Reinforced mounting points absorb vibration and prevent stress fractures.

The Filtration Logic: Permanently bonded into this frame is the mesh. Its weave density is a careful balance: fine enough to block pests and debris, yet open enough to allow critical airflow for driver comfort. The mesh is also designed for high visibility, ensuring no obstruction of the side mirrors.

The Service Logic: As an Assy, these parts are replaced as a single unit. Technicians should not attempt to repair a torn mesh or cracked frame. Replacement of the entire Front Door Insect Screen Assembly is the only way to guarantee a correct fit, proper mesh tension, and a rattle-free cabin.

The second half of this system, marked as item 2, is the sealing component. A Front Door Insect Screen Assembly cannot function in isolation; it relies on these weatherstrips to complete the environmental seal of the door.

1. Component: ‘Left Front Door Window Inner Weatherstrip Assy’ (6102065BD04)

This is the inner weatherstrip, or dew wipe, for the driver’s side (Mark 2, Left). It mounts on the top edge of the interior door trim panel and presses against the inner surface of the window glass.

2. Component: ‘Right Front Door Window Inner Weatherstrip Assy’ (6102070BD04)

This is the corresponding inner weatherstrip for the passenger’s side (Mark 2, Right). It provides the same sealing, wiping, and stabilizing functions as the left-side component.

The Sealing Logic (Applies to both): This component serves multiple functions. It creates a final barrier against drafts from within the door shell. It also stabilizes the window glass, preventing rattles, and ‘wipes’ the glass clean as it retracts.

These assemblies feature a rigid core for secure attachment to the door panel and a soft, flocked-rubber lip for a flexible, low-friction seal. This low-friction design is critical to prevent straining the window regulator motor.

The System Integration Logic: These weatherstrips are listed with the Front Door Insect Screen Assembly because they work as a unified system. A failed inner weatherstrip (Mark 2) compromises the entire cabin seal.

If this seal is hardened or cracked, it fails to dampen vibrations, which can transmit to the Front Door Insect Screen Assembly (Mark 1), causing a rattle. It also allows dust and air to bypass the filtration system, defeating its purpose.

The Service Logic: During any service of the door, window, or the Front Door Insect Screen Assembly itself, these weatherstrips must be inspected. If the felt lip is compressed or the rubber is brittle, the part must be replaced. Failure to do so will result in an incomplete repair.

The following table provides the complete, detailed breakdown of all 4 specified component assemblies associated with the Front Door Insect Screen Assembly system for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. Note that the primary assembly (Mark 1) is supplied as a complete left or right unit, while the associated weatherstrip (Mark 2) is also a distinct left/right assembly.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 6103105BD04 | Left Front Door Insect Screen Assy | 1 |

| 1 | 6103110BD04 | Right Front Door Insect Screen Assy | 1 |

| 2 | 6102065BD04 | Left Front Door Window Inner Weatherstrip Assy | 1 |

| 2 | 6102070BD04 | Right Front Door Window Inner Weatherstrip Assy | 1 |

The specifications for this Front Door Insect Screen Assembly system are defined by its dual role as a physical barrier and an environmental seal, engineered for the specific demands of the CA3250P66K2L1T1E chassis.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | Door Assembly, Cabin Sealing & Filtration |

| Primary Component | ‘Left/Right Front Door Insect Screen Assy’ |

| Associated Component | ‘Left/Right Front Door Window Inner Weatherstrip Assy’ |

| Screen Frame Material | High-Impact, UV-Stabilized Polymer Composite |

| Screen Mesh Material | High-Tensile Coated Fiberglass or Polyester |

| Weatherstrip Material | Dual-Durometer EPDM Rubber with Flocked Lip |

| Key Feature | Provides insect, dust, and debris protection |

| Design | Fixed-position screen, independent window operation |

| Service Type | Full Assembly Replacement (Left or Right units) |

| Total Component Types | 4 (2x Screen Assy, 2x Weatherstrip Assy) | Normal-mode: 0

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.