Rear Suspension Assembly For Cab: Integrating 10 Advanced Dampening Units for Flawless Driver Comfort

The Rear Suspension Assembly For Cab is the secondary isolation stage for the driver’s environment on the CA3250P66K24L1TE5Z dump truck. While the front suspension handles the primary hinge pivot loads, this rear assembly manages the complex vertical and lateral oscillations generated by the tandem rear axles. In the Russian mining sector, where haul roads are notoriously uneven, the Rear Suspension Assembly For Cab is critical for decoupling the cab from the chassis’s high-frequency vibrations. This system employs hydraulic locks, coil springs, and specialized shock absorbers to create a floating cab effect, significantly reducing driver fatigue and protecting sensitive dashboard electronics from shock damage.

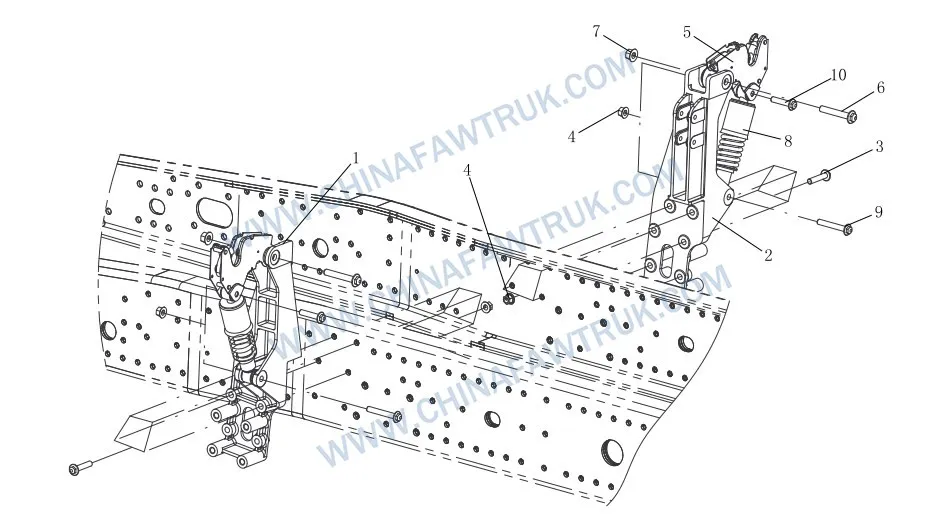

Rear Suspension Assembly For Cab

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5001281-55R | Left Rear Suspension Bracket | 1 |

| 2 | 5001282-55R | Right Rear Suspension Bracket | 1 |

| 3 | Q1841455 | Hexagon Flange Bolt (Coarse Shank/Standard) | 8 |

| 4 | CQ32614F6 | Hexagon Flange Lock Nut | 12 |

| 5 | 5004060-A01-C00 | Cab Hydraulic Lock Assembly | 2 |

| 6 | Q18416110F6 | Hexagon Flange Bolt (Coarse Shank/Standard) | 2 |

| 7 | CQ32616F6 | Hexagon Flange Lock Nut | 2 |

| 8 | 5001320-A01-C00 | Rear Suspension Spring and Shock Absorber Assembly | 2 |

| 9 | Q1841495F6 | Hexagon Flange Bolt (Coarse Shank/Standard) | 2 |

| 10 | Q1841470F6 | Hexagon Flange Bolt (Coarse Shank/Standard) | 2 |

Active Damping and Suspension Logic

The heart of the Rear Suspension Assembly For Cab is the Rear Suspension Spring and Shock Absorber Assembly (Part No. 5001320-A01-C00). This unit combines a coil spring with a hydraulic damper in a single coaxial package. The spring rate is specifically tuned for the weight of the J6P day cab, supporting the structure while allowing for controlled vertical movement. The integrated shock absorber dampens this motion, preventing the “pogo stick” effect that can occur after hitting a large bump. In the Rear Suspension Assembly For Cab, the valving of the shock absorber is optimized for the low-speed, high-amplitude events typical of off-road driving, ensuring that the cab settles quickly after a disturbance.

This coil-over shock unit is anchored by the Left Rear Suspension Bracket (Part No. 5001281-55R) and Right Rear Suspension Bracket (Part No. 5001282-55R). These brackets are fabricated from heavy-gauge steel to withstand the cyclical loading of the suspension. Their geometry is designed to transfer vertical loads into the chassis rails while minimizing lateral sway. The Rear Suspension Assembly For Cab relies on the rigidity of these brackets to maintain the alignment of the suspension geometry, preventing the cab from leaning or twisting relative to the frame.

The performance of the Rear Suspension Assembly For Cab is particularly critical in the Russian Arctic, where frozen ground transmits harsh vibrations. The hydraulic fluid within the shock absorbers is formulated with a high viscosity index to maintain consistent damping performance across a wide temperature range. This ensures that the ride quality does not degrade when the truck is started in -40°C conditions, protecting the driver from the bone-jarring harshness of a frozen suspension.

Hydraulic Locking Mechanism

A unique feature of the Rear Suspension Assembly For Cab is the Cab Hydraulic Lock Assembly (Part No. 5004060-A01-C00). This component serves as the latching mechanism that secures the cab in the driving position. Unlike a simple mechanical latch, this hydraulic unit works in conjunction with the cab tilt system. When the cab is lowered, the hydraulic lock engages automatically, clamping the cab frame to the suspension arch. This positive locking action prevents the cab from bouncing free of its mounts during extreme chassis articulation.

The hydraulic lock also incorporates a safety switch logic. It confirms to the instrument cluster that the cab is fully locked down. If the lock is not engaged—perhaps due to ice in the mechanism—a warning light alerts the driver, preventing vehicle operation with an unsecured cab. The Rear Suspension Assembly For Cab thus integrates mechanical security with electronic monitoring, a vital redundancy for safety in remote operations.

Maintenance of the hydraulic lock involves checking for fluid leaks and ensuring the hook mechanism is free of debris. In the muddy environment of a mine, dirt can pack into the latch area. The FAW design shields the lock mechanism within the suspension arch, but regular cleaning is still recommended to ensure the Rear Suspension Assembly For Cab functions correctly every time the cab is tilted for engine service.

Fastening and Assembly Logic

The structural integrity of the Rear Suspension Assembly For Cab is maintained by a series of high-strength flange bolts. The assembly uses Hexagon Flange Bolt (Coarse Shank/Standard) in various lengths (Part Nos. Q1841455, Q18416110F6, Q1841495F6, Q1841470F6) to secure the brackets and shock absorbers. The “Coarse Shank” design provides maximum shear strength, essential for resisting the lateral forces generated when the heavy cab sways during cornering. The flange head distributes the clamping load, eliminating the need for separate washers that could be lost during field repairs.

These bolts are paired with Hexagon Flange Lock Nut units (Part Nos. CQ32614F6 and CQ32616F6). The locking feature is critical in the high-vibration environment of a dump truck. Manual retightening of suspension bolts is a standard maintenance task, but the self-locking nuts provide a safety margin between intervals. The Rear Suspension Assembly For Cab utilizes “F6” plating specification, indicating a high-grade corrosion-resistant coating (often Geomet or Dacromet) capable of withstanding the aggressive road salts used in Russia.

Correct torque application is vital for the Rear Suspension Assembly For Cab. Over-tightening can crush the shock absorber bushings, leading to harsh ride quality and premature failure. Under-tightening can allow the mounting holes to wallow out, destroying the brackets. FAW specifies precise torque values for each bolt size, ensuring that the clamping force is sufficient to hold the assembly rigid without damaging the components.

Serviceability and Component Replacement

The modular design of the Rear Suspension Assembly For Cab simplifies component replacement. The shock absorber and spring unit can be unbolted and removed without disturbing the main brackets or the hydraulic lock. This allows for quick replacement of wear items in the field. Fleet mechanics should inspect the shock absorbers for oil leaks and the coil springs for fractures, which can occur due to metal fatigue in extreme cold.

When replacing the Rear Suspension Spring and Shock Absorber Assembly, it is recommended to replace both sides simultaneously to maintain balanced handling. A mismatched suspension setup can cause the cab to lean, putting uneven stress on the front hinges. Using genuine FAW parts ensures that the spring rate and damping characteristics match the original specification of the Rear Suspension Assembly For Cab.

The Cab Hydraulic Lock Assembly is a more complex unit to service, involving hydraulic lines. Any work on this component requires depressurizing the tilt system. Regular inspection of the hydraulic hoses leading to the lock is essential; chafing or cracking can lead to a fluid leak that disables the cab tilt function. Proactive maintenance of the Rear Suspension Assembly For Cab ensures that the driver’s workspace remains safe, comfortable, and accessible.

Conclusion: Comfort Meets Capability

The Rear Suspension Assembly For Cab is a sophisticated system that bridges the gap between operator comfort and heavy-duty capability. By isolating the cab from the chassis with 10 precision-engineered components, it transforms the driving experience, reducing fatigue and protecting equipment. From the active damping of the shock absorbers to the secure latching of the hydraulic lock, every part plays a role in the vehicle’s overall performance.

For fleet managers, the Rear Suspension Assembly For Cab is an investment in productivity. A comfortable driver is an alert driver, and a protected cab is a durable cab. By maintaining this suspension system with genuine parts and regular inspections, operators ensure that their FAW dump trucks remain reliable assets in the challenging environment of the Russian heavy transport sector.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.