Front Suspension Assembly For Cab: Anchoring 9 Critical Mounts for Superior Arctic Ride Quality

The Front Suspension Assembly For Cab is the structural foundation that isolates the driver’s environment from the harsh kinetic energy of the chassis on the FAW CA3250P66K24L1TE5Z dump truck. In the demanding logistics landscape of the Russian Federation, where frozen haul roads and extreme temperature gradients create relentless vibration, the performance of the Front Suspension Assembly For Cab is directly linked to operator fatigue and vehicle longevity. This assembly acts as the primary interface between the rigid frame rails and the floating cab structure, utilizing a sophisticated arrangement of hinge brackets, high-tensile bolts, and cushioning plates. By effectively managing the torsional stresses and vertical shocks generated during heavy-duty mining operations, the Front Suspension Assembly For Cab ensures that the cab remains a stable command center, protecting sensitive electronics and providing the comfort necessary for extended shifts in sub-zero conditions.

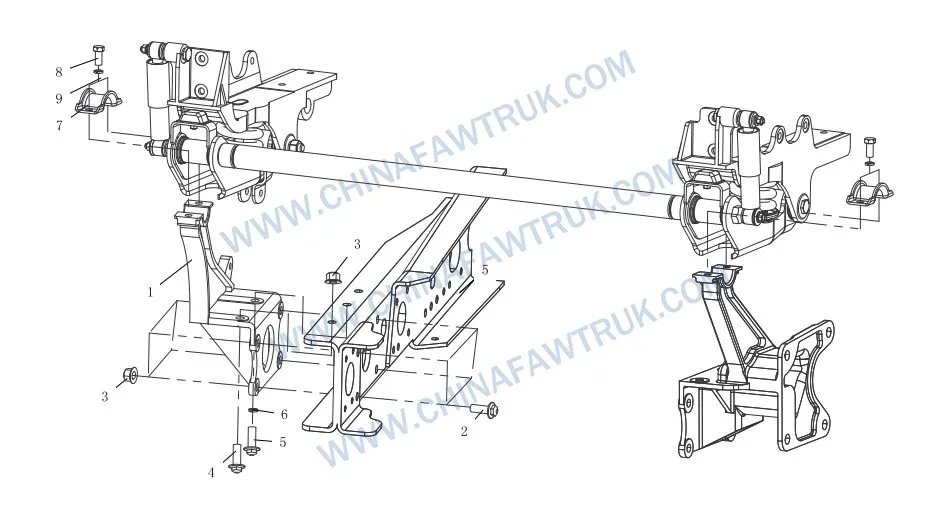

Front Suspension Assembly For Cab

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5001012-99C | Right Hinge Bracket – Cab | 1 |

| 2 | Q1841665T | Hexagon Flange Bolt (Coarse Shank/Standard) | 4 |

| 3 | CQ32616 | Hexagon Flange Lock Nut | 5 |

| 4 | CQ1501665 | Hexagon Head Bolt | 1 |

| 5 | CQ1501655 | Hexagon Head Bolt | 1 |

| 6 | Q40316 | Spring Washer | 1 |

| 7 | 5001016-A01 | Cab Front Suspension Cushion Cover Plate | 2 |

| 8 | CQ1501430F6 | Hexagon Head Pilot Bolt | 4 |

| 9 | Q40314F6 | Spring Washer | 4 |

Structural Hinge Architecture

The cornerstone of the Front Suspension Assembly For Cab is the heavy-duty Right Hinge Bracket – Cab (Part No. 5001012-99C). This component is a precision-cast or fabricated steel unit that serves as the pivot point for the entire cabin tilting mechanism. In the Russian Arctic, where steel can become brittle at temperatures below -40°C, the metallurgy of this bracket is critical. It must withstand not only the static weight of the cab but also the dynamic g-forces experienced when the truck hits potholes or navigates corrugated ice roads. The design of the Front Suspension Assembly For Cab integrates this bracket to allow for the necessary vertical travel of the suspension elements while maintaining rigid lateral stability, preventing the cab from swaying excessively during cornering.

The connection between the hinge bracket and the chassis frame is secured by a series of high-strength fasteners within the Front Suspension Assembly For Cab. Specifically, the Hexagon Head Bolt (Part No. CQ1501665 and CQ1501655) and the Hexagon Flange Bolt (Coarse Shank/Standard) (Part No. Q1841665T) are employed to create a non-slip friction grip. The “Coarse Shank” design of the flange bolts provides superior shear resistance, essential for preventing the bracket from shifting under load. This robust fastening strategy is a defining feature of the Front Suspension Assembly For Cab, ensuring that the primary structural interface remains secure even after years of operation in the punishing vibration environment of a mining site.

Furthermore, the Front Suspension Assembly For Cab incorporates a safety-critical design where the hinge axis aligns perfectly with the hydraulic tilt cylinder’s geometry. This alignment is maintained by the precision machining of the bracket’s bore. Any wear or deformation in this component would lead to misalignment during the cab tilting process, potentially causing the hydraulic system to bind or fail. By using the genuine Front Suspension Assembly For Cab components, operators ensure that the geometric integrity of the cab tilt mechanism is preserved, allowing for safe engine access during maintenance intervals.

Fastener Engineering and Security

The integrity of the Front Suspension Assembly For Cab relies heavily on its specialized fastening system. The assembly utilizes Hexagon Flange Lock Nut (Part No. CQ32616) units to secure the main mounting bolts. These nuts feature an integrated flange that distributes the clamping load over a wider surface area, preventing the bolt head from crushing the bracket material. Additionally, the locking feature—often a nylon insert or distorted thread—prevents the nut from backing off under the high-frequency vibration characteristic of diesel engines. This self-locking capability is vital for the Front Suspension Assembly For Cab, as manual retightening of these hard-to-reach components is often overlooked during routine service.

The Front Suspension Assembly For Cab also employs Hexagon Head Pilot Bolt (Part No. CQ1501430F6) fasteners. The “pilot” point on these bolts aids in alignment during assembly, guiding the bolt into the threaded hole without cross-threading—a common issue when performing repairs in awkward positions or with gloved hands in cold weather. These bolts are paired with Spring Washer (Part No. Q40314F6) units, which act as active tensioning devices. As the metal of the Front Suspension Assembly For Cab contracts in the bitter Russian winter, the spring washer expands to maintain preload on the joint, ensuring that the connection never becomes loose.

Surface treatment of these fasteners is another aspect of the Front Suspension Assembly For Cab logic. The bolts and nuts are typically treated with a zinc-flake or dacromet coating to resist the corrosive effects of road salts and de-icing chemicals used on Russian highways. Corrosion seizing can turn a simple bushing replacement into a nightmare requiring torches and grinders. The high-quality plating on the Front Suspension Assembly For Cab hardware ensures that the system remains serviceable, allowing for efficient maintenance and reducing downtime for the fleet operator.

Cushioning and Vibration Isolation

At the heart of the ride comfort provided by the Front Suspension Assembly For Cab is the interaction between the rubber bushings (typically housed within the bracket) and the Cab Front Suspension Cushion Cover Plate (Part No. 5001016-A01). This cover plate is not merely a cosmetic shield; it serves a crucial structural function by compressing the rubber cushion elements to the correct preload. By containing the rubber, the plate modifies the stiffness of the mount, tuning the natural frequency of the cab suspension to avoid resonance with the chassis. The Front Suspension Assembly For Cab is thus tuned to filter out the high-frequency road noise while absorbing the larger amplitude shocks from potholes.

The Front Suspension Assembly For Cab is exposed to significant environmental stress. The cover plate protects the sensitive rubber elements from direct exposure to sunlight, oil, and road grime, which can degrade the rubber and lead to premature failure. In the Russian winter, the rubber can become hard, losing its damping properties. The design of the Front Suspension Assembly For Cab ensures that the cushion is loaded in a way that maintains its elasticity and effectiveness across a wide temperature range, preventing the “crashing” sensation of a bottomed-out suspension.

Proper installation of the cover plate is essential for the function of the Front Suspension Assembly For Cab. If the bolts securing the plate are over-torqued, the rubber can be crushed, transmitting excessive vibration to the driver. If under-torqued, the plate can rattle or allow the bushing to migrate. The Front Suspension Assembly For Cab design includes positive stops or shoulder bolts to ensure the correct compression is achieved every time, removing the guesswork from the assembly process and guaranteeing consistent ride quality.

Maintenance and Replacement Protocols

Maintaining the Front Suspension Assembly For Cab is a critical aspect of fleet management for the CA3250 dump truck. Regular inspections should focus on the condition of the Right Hinge Bracket – Cab for stress cracks, particularly around the bolt holes. The Front Suspension Assembly For Cab is subjected to millions of stress cycles over its life, and fatigue failure is a possibility in high-mileage vehicles. Any sign of movement between the bracket and the frame indicates loose fasteners, requiring immediate re-torquing or replacement of the Hexagon Flange Lock Nut units.

When replacing components of the Front Suspension Assembly For Cab, it is imperative to replace the Spring Washer (Part No. Q40316 and Q40314F6) and lock nuts. These are single-use items; once compressed or torqued, they lose their locking ability. Reusing old hardware on the Front Suspension Assembly For Cab invites failure, potentially leading to a detached cab mount which is a severe safety hazard. Fleet mechanics should always keep a stock of the specific bolts and washers listed in the Front Suspension Assembly For Cab breakdown to ensure repairs are done correctly.

Finally, the alignment of the Front Suspension Assembly For Cab must be checked after any collision repair or major chassis work. A misaligned hinge bracket can cause the cab to sit crookedly, affecting the latching of the rear mounts and the alignment of the steering column. The Front Suspension Assembly For Cab features slotted holes or shims to allow for fine-tuning of the cab position. Ensuring the cab is square to the frame is essential for the longevity of all cab-to-chassis connections and the proper operation of the Front Suspension Assembly For Cab.

Conclusion: The Bedrock of Cabin Stability

The Front Suspension Assembly For Cab is a sophisticated mechanical system that performs the vital role of connecting the driver to the machine while isolating them from its harshness. Comprising 9 essential components, from the massive hinge bracket to the specialized pilot bolts, this assembly is engineered to survive the toughest conditions on earth. The Front Suspension Assembly For Cab is not just a set of parts; it is the guarantee of a stable, comfortable, and safe working environment.

For fleet operators, investing in the maintenance of the Front Suspension Assembly For Cab yields direct returns in driver satisfaction and vehicle uptime. A well-maintained suspension protects the expensive cab structure from stress fractures and ensures that the vehicle remains a productive asset in the Russian mining sector. By utilizing genuine FAW parts for the Front Suspension Assembly For Cab, operators ensure that the original engineering standards are upheld, mile after punishing mile.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.