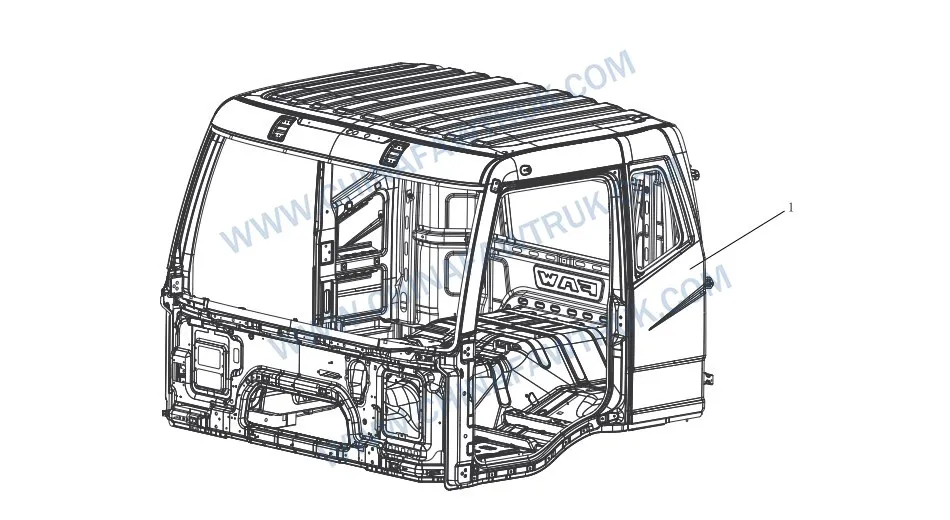

Assemblage de cabine soudé russe FAW: La forteresse d'acier assure la survie et l'intégrité structurelle dans l'Arctique

Le Assemblage de cabine soudé russe FAW is the fundamental survival cell and command center for the CA3250P66K24L1TE5Z dump truck. In the hostile operating environment of the Russian Federation, where external temperatures can plummet to -50°C and haul roads are unforgivingly rough, the structural integrity of the cabin is the driver’s primary line of defense. This assembly represents the bare metal skeleton and skin of the J6P cab, fully welded and primed, ready to be outfitted with interior trim and glass. Engineered with high-tensile steel and reinforced impact zones, le Assemblage de cabine soudé russe FAW provides the necessary rigidity to withstand chassis torsion while offering a hermetically sealed environment against the biting arctic wind.

Assemblage de cabine soudé russe FAW

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 5000040BB35 | Welded Cab Assembly | 1 |

Structural Engineering for Crashworthiness

La fonction première du Assemblage de cabine soudé russe FAW is to provide a passive safety cell for the driver. Constructed from high-strength stamped steel panels, the assembly features a “cage” design concept. The A-pillars and B-pillars are reinforced with multi-layer steel to withstand significant vertical loads, a critical requirement for surviving rollover accidents in mining quarries. The floor pan of the Assemblage de cabine soudé russe FAW is stiffened with longitudinal beams that resist deformation during frontal impacts, ensuring that the driver’s leg space is preserved even in a collision.

Welding precision is paramount in the construction of the Assemblage de cabine soudé russe FAW. FAW utilizes automated robotic spot welding for the main seams, ensuring consistent penetration and weld nugget size. This consistency translates to a rigid unibody structure that does not squeak or rattle over time. In the context of the Russian market, where trucks often operate on washboard gravel roads for thousands of kilometers, the fatigue resistance of these welds is vital. A lesser cab would develop stress cracks at the door frames or window apertures, compromising the seal and structural integrity.

Le Assemblage de cabine soudé russe FAW also integrates specific crumple zones in the front fascia mounting area. These zones are designed to absorb low-speed impact energy, reducing repair costs for minor accidents while directing high-speed impact forces away from the occupant cell. By prioritizing structural rigidity and energy absorption, le Assemblage de cabine soudé russe FAW meets international safety standards, providing peace of mind to operators working in hazardous conditions.

Thermal Isolation and Sealing Logic

For the Russian “Zone froide” spécification, le Assemblage de cabine soudé russe FAW undergoes a specialized manufacturing process to ensure thermal efficiency. The bare metal shell is designed with minimal through-holes to reduce air leakage. Every seam in the Assemblage de cabine soudé russe FAW is sealed with a high-grade automotive sealant before painting. This attention to sealing prevents the “chimney effect,” where warm air escapes through the roof while drawing freezing air in through the floor, a common issue in poorly sealed trucks.

The double-wall construction of the Assemblage de cabine soudé russe FAW in key areas creates a dead air space that acts as a natural insulator. En outre, the firewall and floor sections are designed to accommodate extra-thick insulation mats (installed later). The mounting points for the heater core and ventilation ducts are precision-stamped to ensure a tight fit, preventing cold drafts from bypassing the heater matrix. Le Assemblage de cabine soudé russe FAW essentially functions as a thermos flask, retaining the heat generated by the auxiliary heaters to keep the driver alive and comfortable.

Moisture management is another critical aspect of the Assemblage de cabine soudé russe FAW conception. Par grand froid, condensation on the inner metal surfaces is inevitable. The assembly features strategically placed drain holes and e-coated internal cavities that allow moisture to escape without causing rust. Ce “breathable” design prevents water from pooling in the rocker panels or door bottoms, s'assurer que le Assemblage de cabine soudé russe FAW does not rot from the inside out.

Corrosion Resistance and Surface Treatment

La longévité du Assemblage de cabine soudé russe FAW is secured through an advanced cathodic electrodeposition (DEC) coating process. Before any topcoat is applied, the entire welded assembly is submerged in an electrically charged paint bath. This process ensures that the primer bonds to every nook and cranny of the Assemblage de cabine soudé russe FAW, including the inside of box sections and between spot-welded flanges. Dans l’environnement salin des routes d’hiver russes, where chemical de-icers are used aggressively, this level of protection is non-negotiable.

The steel used in the Assemblage de cabine soudé russe FAW is typically double-sided galvanized sheet metal. This provides a sacrificial zinc layer that protects the steel substrate even if the paint is scratched by flying gravel. The underbody of the cab is further treated with a stone-chip resistant coating. This rubberized layer absorbs the impact of rocks thrown up by the front tires, preventing them from chipping the paint and exposing the metal of the Assemblage de cabine soudé russe FAW to corrosion.

Pour le marché russe, le Assemblage de cabine soudé russe FAW may also receive additional wax injection in the lower cavities. This waxy coating creeps into seams and repels water, providing a final barrier against the corrosive slurry that accumulates on the truck during operation. By combining galvanized steel, CED priming, and protective coatings, le Assemblage de cabine soudé russe FAW is built to resist rust for the entire service life of the vehicle.

Replacement and Repair Strategy

In the event of a severe rollover or collision, repairing a damaged cab shell is often economically unviable and structurally unsafe. Le Assemblage de cabine soudé russe FAW is supplied as a complete “corps en blanc” unité (or painted shell), allowing for a clean swap. This strategy ensures that the structural integrity of the vehicle is fully restored to factory specifications. Attempting to straighten and weld a crushed cab pillar can leave hidden weaknesses; remplacer l'ensemble Assemblage de cabine soudé russe FAW is the only way to guarantee driver safety.

Lors de l'installation d'un nouveau Assemblage de cabine soudé russe FAW, it is critical to transfer the VIN plate and inspect all rubber body mounts. The mounting points on the new assembly are precision-aligned, but the chassis brackets may be bent from the accident. Technicians must ensure that the Assemblage de cabine soudé russe FAW sits square on the frame to prevent stress on the latch mechanism and windshield glass.

Pour les exploitants de flotte, keeping a spare Assemblage de cabine soudé russe FAW is generally not necessary due to its size, but having a reliable supply chain for this component is vital. Dans les opérations minières, cab damage is a leading cause of long-term vehicle downtime. Knowing that a factory-spec Assemblage de cabine soudé russe FAW is available ensures that a valuable asset can be returned to service quickly and safely, minimizing the financial impact of accidents.

Conclusion: The Shell of Safety

Le Assemblage de cabine soudé russe FAW is the single largest and most complex component of the vehicle’s bodywork. It is not just a box for the driver; it is a highly engineered survival cell designed to withstand impact, froid, et corrosion. Its robust welded construction and advanced surface treatments make it uniquely clearer suited for the harsh realities of the Russian heavy transport sector.

Pour les gestionnaires de flotte, l'état du Assemblage de cabine soudé russe FAW is a direct reflection of the fleet’s safety standards. A structurally sound, rust-free cab protects the driver and enhances the resale value of the truck. By understanding the engineering behind this assembly and choosing genuine replacements when necessary, les opérateurs s’assurent que leurs véhicules restent en sécurité, confortable, and productive assets for years to come.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.