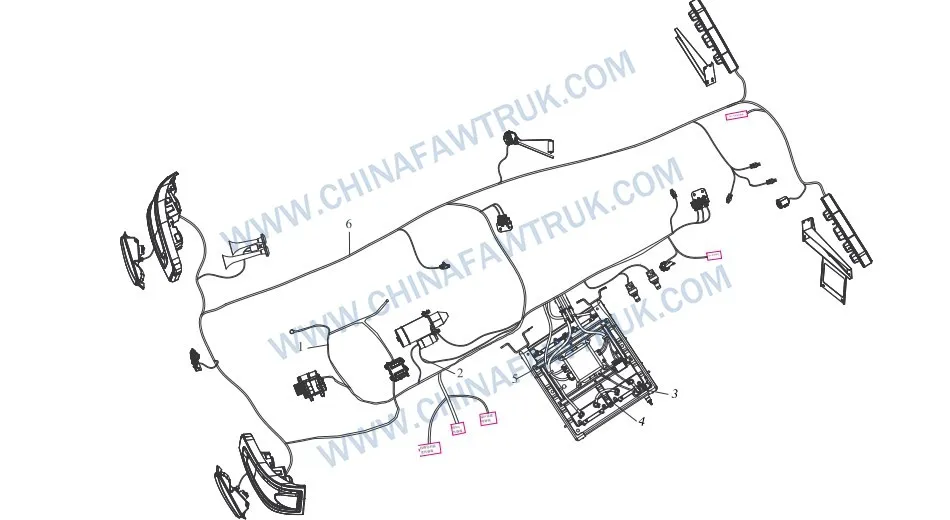

Logique du faisceau de câblage du châssis russe FAW: La dorsale électrique à 6 nœuds défiant la résistance arctique

Le Faisceau de câblage de châssis russe FAW logic assembly serves as the primary vascular system for the CA3250P66K24L1TE5Z dump truck’s electrical grid. In the unforgiving cold of the Russian Federation, where wire insulation tends to stiffen and electrical resistance fluctuates wildly, maintaining a stable flow of current between the battery, entrée, and chassis components is a critical engineering challenge. This assembly integrates heavy-gauge grounding cables, high-current power feeds, and specialized weather-sealed connectors into a cohesive network. Designed to withstand extreme vibration and temperatures as low as -50°C, le Faisceau de câblage de châssis russe FAW ensures that the vehicle’s electrical pulse remains strong and uninterrupted.

Faisceau de câblage de châssis russe FAW

| Non. |

Numéro de pièce |

Nom de la pièce |

Quantité |

| 1 | 3724070-76UN | Ground Cable Assembly – Engine to Frame | 1 |

| 2 | 3724100-55R. | Power Cable Assembly – Main Switch to Starter & Chassis Fuse Box | 1 |

| 3 | 3724175-92W | Assemblage de câbles – Battery Positive to Main Power Switch | 1 |

| 4 | 3724180-50UN | Assemblage de câbles – Battery Interconnect | 1 |

| 5 | 3724200-55UN | Ground Cable Assembly – Batterie à cadrer | 1 |

| 6 | 3724265-58H | Chassis Wiring Harness Assembly | 1 |

High-Current Power Distribution Architecture

The electrical integrity of the vehicle is anchored by the primary power feeds that connect the energy storage system to the heavy consumers. Le Assemblage de câbles – Battery Positive to Main Power Switch (Partie no. 3724175-92W) is the critical first link, carrying the full amperage of the battery bank. Dans l'Arctique russe, high current flow generates internal heat while the external environment remains freezing. Le Faisceau de câblage de châssis russe FAW utilizes a specialized “92W” insulation compound that resists this thermal cycling fatigue, preventing the sheathing from cracking and ensuring the live conductor does not short circuit against the metal battery box.

Once power passes through the main switch, it is distributed by the Power Cable Assembly – Main Switch to Starter & Chassis Fuse Box (Partie no. 3724100-55R.). This dual-purpose cable is the lifeline for engine starting. It must deliver hundreds of amps to the starter motor with minimal voltage drop, even when the battery chemistry is sluggish due to cold. Simultanément, it feeds the chassis fuse box, ensuring that auxiliary heaters and lights remain powered. The reliability of this system relies on the reinforced terminal crimp design of the Faisceau de câblage de châssis russe FAW, which handles the mechanical stress of engine vibration.

Connecting the two 12V batteries in series to create the 24V system is the job of the Assemblage de câbles – Battery Interconnect (Partie no. 3724180-50UN). This short but vital cable is often the most overlooked component. If its terminals corrode or loosen, the entire electrical system fails. Pour lutter contre cela, the interconnect cables within the Faisceau de câblage de châssis russe FAW utilize lead-tin plated terminals to resist the acidic vapors present within the battery box, ensuring a solid, low-resistance connection that endures years of service.

Grounding Logic: The Foundation of Reliability

Electrical circuits are only as good as their ground return path. Le Faisceau de câblage de châssis russe FAW employs a redundant grounding strategy to ensure absolute continuity. Le Ground Cable Assembly – Batterie à cadrer (Partie no. 3724200-55UN) establishes the primary reference potential for the entire truck. A poor connection here can cause everything from dim lights to ECU communication errors. FAW uses a braided copper strap or fine-strand heavy-gauge cable for this application to maximize flexibility and fatigue resistance.

Equally important is the Ground Cable Assembly – Engine to Frame (Partie no. 3724070-76UN). Since the engine is mounted on rubber isolators, it is electrically insulated from the chassis. Without this dedicated ground strap provided by the Faisceau de câblage de châssis russe FAW, the starter motor and alternator would try to ground through the transmission bearings or accelerator linkage, leading to catastrophic mechanical damage. Le “76UN” spec ensures this strap is resistant to oil, carburant, and the high heat of the engine bay, maintaining a clean electrical path.

Dans l’environnement salin des routes d’hiver russes, ground points are the first to corrode. This logic assembly utilizes star washers and tin-plated contact areas on the chassis to bite through surface oxidation and paint. This mechanical “mordant” action ensures that the ground connection remains gas-tight and free of resistance, even as the steel frame rails undergo surface rusting over the vehicle’s lifespan, preserving the functional integrity of the Faisceau de câblage de châssis russe FAW grounding network.

Signal Integrity and Harness Protection

The main artery for sensor data and control signals is the Chassis Wiring Harness Assembly (Partie no. 3724265-58H). This complex loom runs the length of the frame, connecting the rear lights, Capteurs ABS, air dryers, and fuel tank senders to the cab. Le “58H” designation of the Faisceau de câblage de châssis russe FAW signifies a heavy-duty, armored construction. The individual wires are bundled within a corrugated split-loom tube, which is then wrapped in a tough, abrasion-resistant tape to complete the physical protection against rock strikes and ice abrasion.

Routing logic is critical for the longevity of the electrical system. The harness is secured to the frame rails using P-clips and standoff brackets that prevent it from rubbing against sharp metal edges. At articulation points, such as near the rear suspension, le Faisceau de câblage de châssis russe FAW features stress-relief loops to accommodate chassis flex without pulling the connectors apart. This attention to mechanical strain ensures that the electrical signals remain uninterrupted during off-road maneuvers in rough terrain.

Connectors within the assembly are of the sealed, weather-pack variety. Silicone seals on each wire entry and a main gasket on the connector body prevent water ingress. In the freeze-thaw cycles of the Russian spring, moisture entering a connector can expand as it freezes, pushing the pins apart (“terminal back-out”) and causing open circuits. The specific design of the Faisceau de câblage de châssis russe FAW mitigates this risk, ensuring reliable communication between the vehicle’s distributed electronic modules.

Protocoles de maintenance et de remplacement

Dépannage du Faisceau de câblage de châssis russe FAW nécessite une approche systématique. Voltage drop testing is the primary diagnostic method. A high voltage drop across a ground cable indicates corrosion or a loose connection. Fleet mechanics should regularly inspect the ground points on the frame and engine block, cleaning them with a wire brush and reapplying dielectric grease to seal out moisture.

Visual inspection of the routing is also vital. Any areas where the corrugated loom is worn through should be repaired immediately to prevent short circuits. When replacing a section of the Chassis Wiring Harness Assembly, it is crucial to use genuine FAW parts. Aftermarket versions of the Faisceau de câblage de châssis russe FAW may use thinner gauge wire or inferior insulation that becomes brittle in the cold, leading to rapid failure in the Russian winter.

Enfin, care must be taken with the battery cables connected to the main loom. The heavy lugs on the Power Cable Assembly et Ground Cable Assembly must be torqued correctly. Loose battery connections can arc, melting the lead battery posts and potentially causing a hydrogen gas explosion. Regular maintenance of the Faisceau de câblage de châssis russe FAW connections ensures safe, reliable starting power and protects the vehicle’s expensive electronic components from voltage spikes.

Conclusion: The Nervous System of the Truck

Le Faisceau de câblage de châssis russe FAW logic assembly is a complex network reduced to 6 manageable, high-impact components. From the massive Power Cable Assembly that brings the engine to life to the intricate Chassis Wiring Harness Assembly that carries vital sensor data, every part is engineered for the specific challenges of the Russian environment.

Pour les exploitants de flotte, the integrity of this wiring system is synonymous with vehicle reliability. A truck with a perfect engine but a failed harness is a stationary asset. By prioritizing the maintenance of grounds, cables, and connectors within the Faisceau de câblage de châssis russe FAW, et en utilisant uniquement des pièces de rechange d'origine, operators ensure that the electrical lifeblood of their fleet continues to flow, quelle que soit la température extérieure.

Emballage et logistique

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.