This is the essential technical guide to the Ensemble de roue avant FAW (front end accessory drive system) Pour le FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This document provides a complete, detailed breakdown of the front-end pulley system, a critical assembly for engine operation.

The function of this system extends far beyond simply spinning. Cet assemblage, referred to here as the Ensemble de roue avant FAW, is responsible for transmitting power from the engine’s crankshaft to all vital accessories, including the alternator, pompe à eau, power steering pump, et compresseur de climatisation.

This guide is designed for service technicians, parts departments, and fleet owners, deconstructing the assembly into its smallest serviceable units. We will analyze each component—from the main support bracket and belt to the automatic tensioner and idler pulleys—to ensure accurate diagnostics, entretien, and parts ordering.

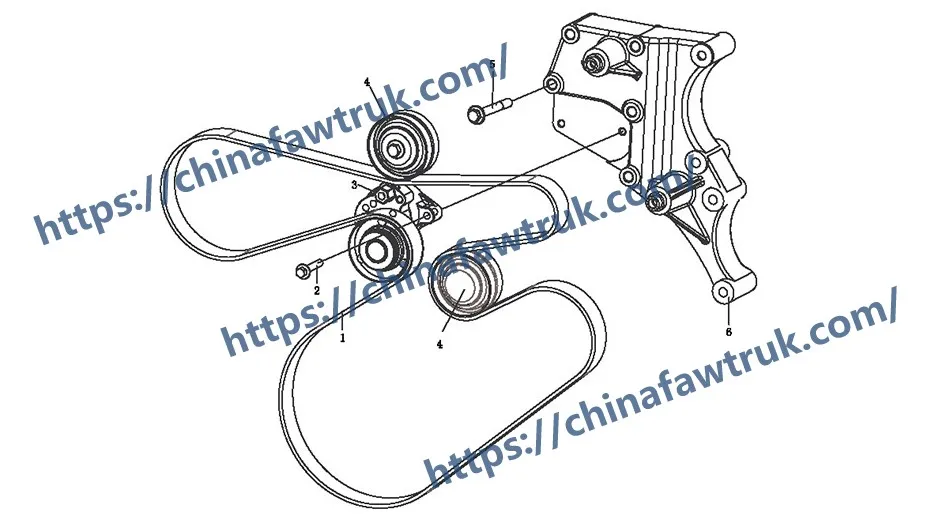

L'ensemble Ensemble de roue avant FAW is built upon two foundational components: the ‘Front Pulley System Bracket’ (1023011-81D) and the ‘Poly-V Belt’ (1023021-81D). The bracket serves as the chassis for the assembly, bolting directly to the engine block. It is a high-strength casting, likely of aluminum or iron, that is precision-machined to provide exact mounting locations for the tensioner and idler pulleys. Its rigidity is essential to prevent flex, which could cause belt misalignment and premature wear.

The ‘Poly-V Belt’ is the component that does the work. En tant que “poly-v” or multi-ribbed belt, it features multiple small V-shaped ribs. This design offers significant advantages over older, single V-belts. It provides a much larger contact area for grip, allowing it to transmit high loads with less tension and a reduced chance of slippage. This design also allows the belt to be more flexible, enabling it to be routed in complex “serpentin” paths, driving multiple accessories from both its ribbed and flat sides.

Made from durable EPDM (Monomère d'éthylène propylène diène) caoutchouc, this belt is designed to resist heat, huile, and cracking for tens of thousands of kilometers. Cependant, it is a primary wear item. Regular inspection for cracks, fraying, or glazing is a critical part of vehicle maintenance. A failure of this single belt will result in an immediate loss of power generation (alternateur) and engine cooling (pompe à eau), leading to a breakdown.

The single most sophisticated component in the Ensemble de roue avant FAW is the ‘Tensioner Pulley Assembly’ (1023010-36D). This device is critical for the system’s longevity and performance, as it solves a fundamental problem: the belt’s tension must remain constant, even as the belt stretches with age and heat, and as engine loads and RPMs fluctuate rapidly.

This is an automatic tensioner, meaning it is not manually set. Inside the main housing, a powerful, calibrated coil spring is mounted in a cartridge. This spring exerts a continuous, precisely calculated amount of force on an arm, which holds the tensioner pulley. This force automatically “takes up the slack” in the belt, ensuring it remains perfectly tensioned at all times. This prevents slippage, which causes squealing noises and poor accessory performance, and it also prevents over-tensioning, which can destroy the bearings in the alternator or water pump.

Modern tensioners like this one also include an internal damping mechanism. This works like a small, integrated shock absorber, which stops the tensioner arm from “flottant” ou “slapping” during rapid acceleration or deceleration (like shifting gears). This damping is crucial for reducing noise and dramatically extending the life of the belt and the tensioner’s own bearing. The ‘Combination Bolts’ (CQ1460835) are specified for its installation, likely featuring a captive washer for secure mounting.

The entire ‘Tensioner Pulley Assembly’ is considered a single serviceable unit. The two primary failure points are the internal spring (which can weaken over time, leading to a loose belt) and the pulley bearing (which can wear out, causing a grinding or whining noise). When a failure is diagnosed, the entire assembly (1023010-36D) is replaced to restore the Ensemble de roue avant FAW to its original factory specifications.

While the tensioner *applies* pressure, the ‘Idler Pulley Assemblies’ (1023015-36D) *guide* the belt. The parts list calls for two of these units. Unlike the tensioner, these idlers are fixed in place (bolted to the ‘Front Pulley System Bracket’) and do not move. Their purpose is purely directional.

Idler pulleys are used for two main reasons. D'abord, they route the belt around obstacles. The front of an engine is a crowded space with engine mounts, coolant hoses, and other components. The idlers are placed to create a clear, non-interfering path for the belt.

Deuxième, they are used to increase the “angle d'enroulement” on other pulleys. Par exemple, by placing an idler pulley near the alternator, the belt can be forced to wrap more than 180 degrees around the alternator’s pulley. This increased surface contact provides superior grip, allowing the alternator to be driven effectively without belt slippage, even under high electrical load.

Just like the tensioner, the ‘Idler Pulley Assembly’ is a simple device composed of a high-quality pulley (which can be flat or ribbed, depending on which side of the belt it contacts) and an internal, high-speed bearing. The bearing is the only wear item. Failure is typically indicated by a high-pitched whining or grinding sound that rises and falls with engine RPM. If an idler bearing seizes, it will instantly destroy the belt. Donc, these are critical inspection points when servicing the Ensemble de roue avant FAW.

L'intégrité du Ensemble de roue avant FAW is dependent on its fasteners. The parts list identifies two types. The ‘Hex Flange Bolt, Canne grossière (Modèle standard)’ (Q1841075) is a heavy-duty bolt, and the list calls for five. These are almost certainly the main bolts that secure the ‘Front Pulley System Bracket’ (1023011-81D) au bloc moteur. The flange design is important as it spreads the clamping load over a wider area without needing a separate washer, ensuring the bracket remains rigid and perfectly aligned.

Le « boulon combiné’ (CQ1460835), dont il y en a deux, is specified for the ‘Tensioner Pulley Assembly’. A combination bolt typically has a captive washer (either a flat washer or a spring lock washer) pré-installé sur le boulon. This simplifies installation and ensures the correct washer is always used, which is vital for a component that is under constant spring-loaded and vibrational stress. Utiliser le bon, factory-specified bolts with the proper torque is not optional; it is mandatory for a safe and reliable repair of the Ensemble de roue avant FAW.

Le tableau suivant fournit l'intégralité, detailed breakdown of all components identified in the ‘Front End Pulley System’ schéma du tracteur FAW CA4251P66K24T1A3E5. Use these part numbers for accurate ordering and service.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1023021-81D | Poly-V Belt | 1 |

| 2 | CQ1460835 | Boulon combiné | 2 |

| 3 | 1023010-36D | Tensioner Pulley Assembly | 1 |

| 4 | 1023015-36D | Ensemble de poulie de renvoi | 2 |

| 5 | Q1841075 | Boulon de bride hexadécimal, Canne grossière (Modèle standard) | 5 |

| 6 | 1023011-81D | Front Pulley System Bracket | 1 |

Les spécifications pour le Ensemble de roue avant FAW (accessory drive) are defined by its interconnected components. This system operates as a single unit to power all engine-driven accessories.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Entraînement d'accessoires avant (Pulley System) |

| Main Bracket Part No. | 1023011-81D |

| Belt Part No. & Taper | 1023021-81D (Poly-V Belt / Serpentine Belt) |

| Ensemble tendeur | 1x Automatic Spring-Loaded (1023010-36D) |

| Idler Pulley Assemblies | 2x Fixed Idler Pulleys (1023015-36D) |

| Attaches clés | Q1841075 (5x), CQ1460835 (2x) |

| Fonction principale | Transmits rotational power from the crankshaft to engine accessories (Par exemple, alternateur, pompe à eau, power steering pump). |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.