Bienvenue dans ce guide technique critique sur le Refroidisseur d'huile moteur FAW (Partie no. 1013010-81D), a vital component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This system is non-negotiable for engine longevity under heavy-duty conditions.

The function of the Refroidisseur d'huile moteur FAW is to regulate the temperature of the engine’s lubricating oil. It uses the engine’s own coolant (antifreeze) as a medium to absorb and carry away excess heat from the oil, ensuring the oil’s viscosity and lubricating properties remain stable under high loads.

This guide is an essential resource for professional engine technicians, gestionnaires de flotte, et spécialistes des pièces détachées. Nous déconstruirons l'ensemble Refroidisseur d'huile moteur FAW assemblée, including its complex heat exchanger core, its integrated pressure-regulating bypass valve, and all associated gaskets, scellés, et attaches.

The heart of the system is the ‘Engine oil cooler assembly’ (1013010-81D). This is the main heat exchanger unit of the Refroidisseur d'huile moteur FAW. Ce composant est un “stacked-plate” type cooler, which is far superior to older “fin-and-tube” designs. It consists of numerous thin, precisely stamped metal plates.

These plates are brazed together in a stack, creating two separate, alternating sets of passages. Hot engine oil is forced through one set of passages, while cool engine coolant is forced through the alternating set in the opposite direction (un “counter-flow” conception). This creates the maximum possible thermal differential, allowing heat to transfer efficiently from the hot oil, through the thin plate, and into the cooler coolant.

The integrity of this core is paramount. Au fil du temps, or due to a manufacturing defect, one of the internal brazed joints can fail, creating a microscopic crack between the oil and coolant passages. This is a catastrophic failure, as it will allow high-pressure engine oil to be forced into the low-pressure cooling system (blowing out hoses) ou, pire, allow corrosive coolant to enter the oil, destroying the engine’s bearings. A failed core in the Refroidisseur d'huile moteur FAW necessitates the replacement of the entire assembly.

The ‘Engine oil cooler gasket’ (1013012-81D) is the single main seal that connects the entire Refroidisseur d'huile moteur FAW assembly to the engine block. C'est un grand, complexe “profil” joint, not a simple flat piece of paper.

This gasket is typically made of a steel carrier plate with precision-molded elastomer (caoutchouc) scellés. It must seal four different passages simultaneously:

A failure of this one gasket is just as catastrophic as an internal core failure. If the seal between the “oil in” et “coolant in” passages breaks down, the oil and coolant will mix, resulting in the “milkshake” of death in the oil pan and radiator. Ce joint est un article à usage unique. À tout moment le Refroidisseur d'huile moteur FAW is removed for service, this gasket *must* be replaced.

The most complex part of the Refroidisseur d'huile moteur FAW is its integrated oil filter base and bypass valve system. The parts list shows a ‘Pressure regulating valve assembly’ (1013060-81D). This valve is a critical safety device. On a cold start-up, the engine’s oil is thick and has a very high viscosity. Forcing this cold, thick oil through the stacked-plate cooler’s tiny passages would create immense back-pressure, potentially starving the engine of oil for several critical seconds.

This pressure regulating valve acts as a **thermostatic bypass**. It is a spring-loaded valve (spring part 1013053A53D) that senses oil pressure (or sometimes temperature). When the oil is cold and thick, the high pressure forces this valve *open*. This allows the oil to *bypass* the cooler core entirely, flowing directly from the pump to the engine’s galleries. This ensures the engine receives oil *immediately* upon startup.

As the engine warms up, the oil thins out, its pressure drops, and the spring (1013053A53D) forces the valve *closed*. This closure then forces 100% of the hot oil to circulate through the Refroidisseur d'huile moteur FAW cœur, as it is now needed for cooling. A failure of this valve is a major problem: si ça reste ouvert, the oil will never be cooled, and the engine will overheat. S'il reste fermé, the engine will be starved of oil on every cold start.

Le Refroidisseur d'huile moteur FAW housing also contains the ‘Full-flow filter connecting bolt’ (1013041-53D), which is the large, threaded “nipple” that the spin-on oil filter attaches to. The entire assembly (cooler and filter) is housed by a complex system of covers and valves: ‘Cover-oil cooler bypass valve’ (1013031-53D), ‘Seat-oil cooler bypass valve’ (1013032-53D), ‘Valve-oil cooler bypass valve’ (1013033-53D), and the associated ‘Seat’ (1013051-53D) and ‘Bypass valve’ (1013052-53D). This entire sub-assembly is what “logiquement” routes the oil through the Refroidisseur d'huile moteur FAW système.

A complex housing like the Refroidisseur d'huile moteur FAW, which manages multiple fluids, is sealed by a large number of components. The parts list details numerous ‘O-rings’ (1013034-53D, 1013037-53D, 083452_1.46_2x3.55) et « Joints’ (CQ72322, Q40106, Q40306). These are used to seal the various valve covers, bouchons, and connecting bolts.

It also includes several ‘Copper Gaskets’ (Q/WC3403_20x28, Q/WC3403_27x35, Q/WC3403_30x40). Ce sont des températures élevées, à haute pression “crush washers.” They are used to seal banjo bolts or large threaded plugs, such as the ‘Inner hex socket screw plug M27x1.5’ (Q/WC3410_M27x1.5). These plugs cap off the galleries created during the manufacturing and machining of the Refroidisseur d'huile moteur FAW logement.

L'ensemble Refroidisseur d'huile moteur FAW assembly is secured to the engine block by a specific set of fasteners. This includes numerous ‘Hex flange bolts’ of various R-types (Q1820810T, Q1820845, Q1820855, Q1821070) and ‘Hex cap bolts’ (CQ1500625). The high quantity and variety of these bolts are necessary to provide precise, even clamping pressure on the main gasket (1013012-81D) to prevent leaks. The proper torque sequence and specification for these bolts are critical during reassembly of the Refroidisseur d'huile moteur FAW.

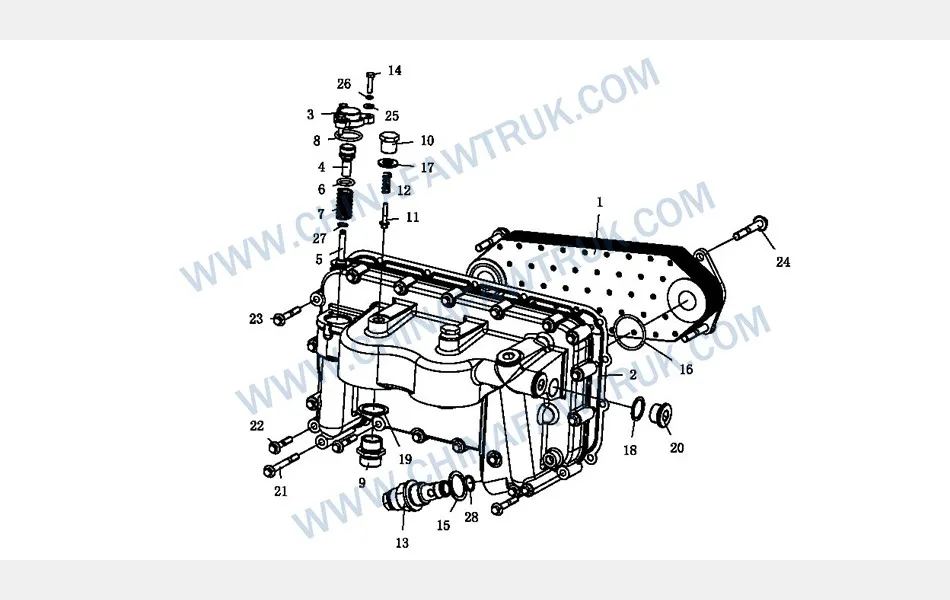

Le tableau suivant fournit l'intégralité, detailed breakdown of all components identified in the ‘Engine Oil Cooler’ schéma du tracteur FAW CA4251P66K24T1A3E5. Un service professionnel du Refroidisseur d'huile moteur FAW requires replacing all O-rings and gaskets.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1013010-81D | Engine oil cooler assembly | 1 |

| 2 | 1013012-81D | Engine oil cooler gasket | 1 |

| 3 | 1013031-53D | Cover-oil cooler bypass valve | 1 |

| 4 | 1013032-53D | Seat-oil cooler bypass valve | 1 |

| 5 | 1013033-53D | Valve-oil cooler bypass valve | 1 |

| 6 | 1013034-53D | O-ring seal-oil cooler bypass valve | 1 |

| 7 | 1013036A53D | Spring-oil cooler bypass valve | 1 |

| 8 | 1013037-53D | O-ring seal-cover | 1 |

| 9 | 1013041-53D | Full-flow filter connecting bolt | 1 |

| 10 | 1013051-53D | Siège | 2 |

| 11 | 1013052-53D | Bypass valve | 2 |

| 12 | 1013053A53D | Printemps | 2 |

| 13 | 1013060-81D | Ensemble de vanne de régulation de pression | 1 |

| 14 | CQ1500625 | Boulon à capuchon hexagonal | 3 |

| 15 | CQ72322 | Bague d'étanchéité | 1 |

| 16 | 083452_1.46_2x3.55 | Joint joint joint | 2 |

| 17 | Q/WC3403_20x28 | Joint en cuivre | 2 |

| 18 | Q/WC3403_27x35 | Joint en cuivre | 3 |

| 19 | Q/WC3403_30x40 | Joint en cuivre | 2 |

| 20 | Q/WC3410_M27x1.5 | Inner hex socket screw plug | 3 |

| 21 | Q1820810T | Boulon à bride hexagonale, tige grossière (Rype R) | 3 |

| 22 | Q1820845 | Boulon à bride hexagonale, tige grossière (Rype R) | 1 |

| 23 | Q1820855 | Boulon à bride hexagonale, tige grossière (Rype R) | 16 |

| 24 | Q1821070 | Boulon à bride hexagonale, tige grossière (Rype R) | 4 |

| 25 | Q40106 | Joint | 3 |

| 26 | Q40306 | Joint à ressort | 3 |

| 27 | Q43108 | Bague de retenue élastique d'arbre | 1 |

| 28 | Q7342422A | O-type rubber seal | 1 |

Les spécifications pour le Refroidisseur d'huile moteur FAW are defined by its complex function as a multi-fluid heat exchanger and integrated oil bypass system. L'ensemble Refroidisseur d'huile moteur FAW assembly is a zero-leak tolerance component.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Refroidisseur d'huile moteur FAW |

| Assemblage principal P/N | 1013010-81D |

| Heat Exchanger Type | Stacked-Plate, Liquide à Liquide (Oil-to-Coolant) |

| Joint principal | 1x Profiled Steel/Elastomer Gasket (1013012-81D) |

| Integrated System 1 | Oil Filter Base (mounts spin-on filter) |

| Integrated System 2 | Cold Oil Bypass (Thermostatic) Valve System |

| Bypass Valve P/N | 1013060-81D (Ensemble de vanne de régulation de pression) |

| Total Main Fasteners | Sur 24 (Q182-series and CQ150-series bolts) |

| Fonction principale | To maintain engine oil at its optimal operating temperature by removing excess heat via the engine’s coolant. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.