Bienvenue dans ce guide technique expert sur le Ensemble logique de vanne de vidange FAW, a critical service component for the cooling system of the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. This assembly is the primary interface for safely servicing the engine’s coolant.

The function of the Ensemble logique de vanne de vidange FAW est de fournir un nettoyage, remote-operated, and accessible drain point for the engine’s radiator. On modern, complex trucks, the radiator’s low point is often inaccessible. Ce “assemblage logique” relocates the *control* of the drain to an easy-to-reach spot, typically via a handle and bracket.

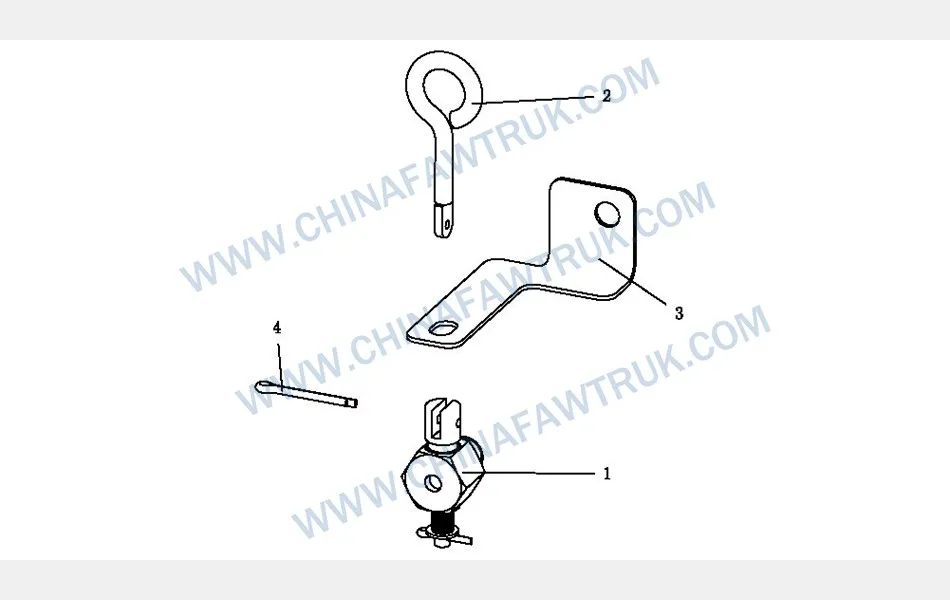

Ce guide est une ressource essentielle pour les techniciens professionnels, responsables de l'entretien de la flotte, et spécialistes des pièces détachées. Nous déconstruirons l'ensemble Ensemble logique de vanne de vidange FAW (Partie no. 1305010-29D) dans ses plus petites unités utilisables, including the valve itself, the remote handle, the mounting bracket, and the simple-but-critical cotter pin.

Le noyau du Ensemble logique de vanne de vidange FAW is the ‘Drain Valve Assembly’ (1305010-29D) lui-même. C'est le “petcock” or tap that is physically threaded into the lowest point of the radiator, or an associated coolant pipe. This is the component that holds back the entire cooling system’s volume of hot, pressurized antifreeze.

This is not a simple plumbing fixture. It must be engineered from materials that will not corrode or degrade when exposed to engine coolant (a mix of glycol and anti-corrosion additives) and extreme temperatures that can range from -40°C to over 120°C. It is typically made of a high-strength brass body or a reinforced, heat-resistant polymer.

The sealing mechanism is critical. The valve uses high-temperature O-rings or a precision-lapped “grille” to create a perfect, drip-free seal, even when under 15-20 PSI of cooling system pressure. A failure of this component is a major issue. Si le Ensemble logique de vanne de vidange FAW fails in the “closed” position (seizes), it makes servicing the coolant a difficult and messy job, requiring a technician to pull a large radiator hose. If it fails in the “ouvrir” position (fuites), it is a catastrophic failure that will drain the engine of coolant, leading to overheating and severe engine damage. La fiabilité du Ensemble logique de vanne de vidange FAW is therefore a critical safety factor.

What truly defines this as a Ensemble logique de vanne de vidange FAW is the remote actuation system. On a large tractor, the radiator drain plug is often impossible to reach without removing shrouds, skid plates, or grilles. Ce “logique” system relocates the point of operation to an accessible, safe location.

The ‘Drain Valve Handle’ (1305013-29D) is the technician’s interface. It is an ergonomic T-handle or lever designed for easy, fonctionnement sans outil. It is typically mounted on the ‘Drain Valve Bracket’ (1305031-29D). This bracket is a rigid, stamped-steel component that bolts to a secure part of the chassis or radiator support, ensuring the handle is held firmly in place and does not bend or flex during use.

The handle is connected to the ‘Drain Valve Assembly’ (1305010-29D) via a long, rigid linkage rod (pas de photo, mais implicite). When the technician pulls or turns the handle, this motion is transferred directly to the valve’s actuator, opening the drain. Ce “logique” c'est ce qui fait que Ensemble logique de vanne de vidange FAW a key feature for serviceability. It allows a technician to drain hot coolant safely, from a distance, without having to put their arms near a hot engine or radiator.

The entire remote system is held together by the smallest component in the Ensemble logique de vanne de vidange FAW: the ‘Cotter Pin’ (Q5003025). C'est un simple, “goupille fendue” made of soft steel.

Its function is to act as a lynchpin. It is inserted through a pre-drilled hole in the handle (1305013-29D) and the linkage rod that connects to the valve. Les deux “legs” of the pin are then bent over, locking the handle to the rod and preventing it from falling off due to vibration.

This pin is a critical, single-use item. During any service that requires disconnecting the handle, this pin must be replaced with a new one. Re-using a fatigued cotter pin is a major risk; if it fails and falls out, the remote handle will become disconnected, rendering the entire Ensemble logique de vanne de vidange FAW inopérable. This small pin is the key to the system’s reliability.

Le Ensemble logique de vanne de vidange FAW is a component that is rarely thought of until it is needed, at which point its function is critical. The primary purpose of the cooling system is to maintain the engine at its optimal operating temperature (environ. 85-95° C). Cependant, this system must be periodically drained for several reasons:

Before the existence of the Ensemble logique de vanne de vidange FAW, the standard procedure was to place a wide pan under the radiator and pull off the main lower hose. This resulted in an uncontrolled, high-volume gush of hot, toxic coolant, spilling over the technician, the floor, and the truck’s subframe. It was messy, dangerous, and environmentally irresponsible.

Le Ensemble logique de vanne de vidange FAW solves all these problems. The technician can first attach a small drain hose to the valve’s outlet, directing the flow cleanly into a container. By using the remote handle, they can then open the valve slowly, controlling the flow and preventing any splashing or burns. This is a massive improvement in both service efficiency and technician safety. Le “logique” de la Ensemble logique de vanne de vidange FAW is therefore a logic of safety and cleanliness.

Le tableau suivant fournit l'intégralité, detailed breakdown of all components identified in the ‘Drain Valve Logic Assembly’ schéma du tracteur FAW CA4251P66K24T1A3E5. Ce Ensemble logique de vanne de vidange FAW is key to safe coolant service.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 1305010-29D | Ensemble de vanne de vidange | 1 |

| 2 | 1305013-29D | Drain Valve Handle | 1 |

| 3 | 1305031-29D | Drain Valve Bracket | 1 |

| 4 | Q5003025 | Goupille fendue | 1 |

Les spécifications pour le Ensemble logique de vanne de vidange FAW are defined by its function as a manual, remote-operated drain for the engine’s high-temperature cooling system. Le Ensemble logique de vanne de vidange FAW must be serviced with care.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Ensemble logique de vanne de vidange FAW |

| Type de système | Remote-Operated Petcock / Vanne de vidange |

| Ensemble de vanne principale | 1x (Partie no. 1305010-29D) |

| Méthode d'actionnement | Manuel (Remote Handle) |

| User Interface | 1x Drain Valve Handle (1305013-29D) |

| Système de montage | 1x Drain Valve Bracket (1305031-29D) |

| Linkage Fastener | 1x Cotter Pin (Q5003025) |

| Associated Fluid | Liquide de refroidissement moteur / Antigel |

| Fonction principale | To provide a safe, faire le ménage, and remote-accessible drain for servicing the cooling system. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.