FAW Russian Transfer-Case Auxiliary Suspension: Engineering 20 Strategic Links for Absolute Driveline Stability

The FAW Russian Transfer-Case Auxiliary Suspension logic assembly serves as the critical stabilizing network for the CA3250P66K24L1TE5Z dump truck. While the main mounts support the vertical weight, this auxiliary system manages the intense reaction torque and longitudinal forces generated during all-wheel-drive operation. In the unforgiving terrain of the Russian Federation, the FAW Russian Transfer-Case Auxiliary Suspension prevents the transfer case from twisting out of alignment, ensuring that power is delivered smoothly to the axles even when ambient temperatures plummet to -40°C.

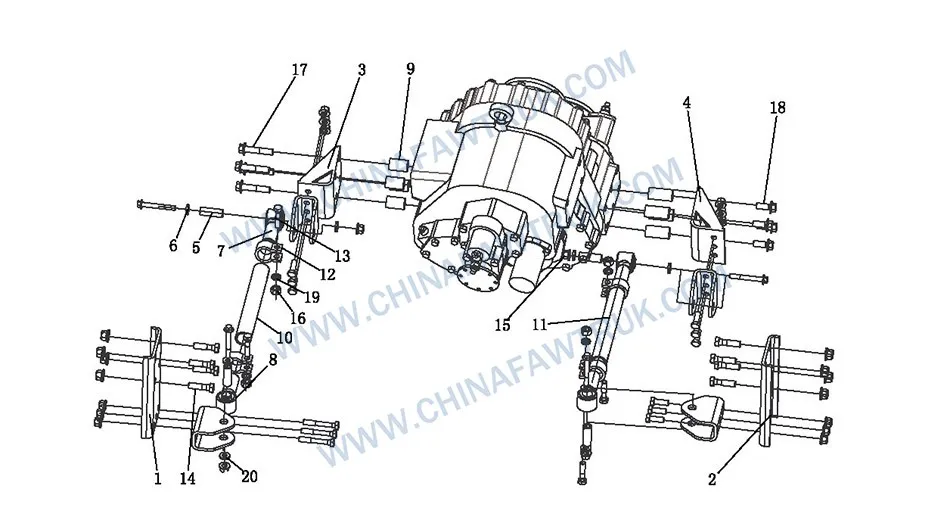

FAW Russian Transfer-Case Auxiliary Suspension Assembly

Stabilization Dynamics: The Auxiliary Pull Rods

The defining components of the FAW Russian Transfer-Case Auxiliary Suspension are the pull rods: Left Auxiliary Pull Rod (Part No. 1806054-55R) and Right Auxiliary Pull Rod (Part No. 1806064-55R). These heavy-duty steel bars act as torque arms. When the transfer case engages the front axle or low range, immense rotational force tries to twist the case within the chassis rails. The FAW Russian Transfer-Case Auxiliary Suspension utilizes these rods to absorb that energy, converting dangerous rotational torque into manageable linear tension and compression forces.

Crucial to this function are the articulating joints: Front Joint Assembly (Part No. 1801055-469) and Rear Joint Assembly (Part No. 1801060-469). In the FAW Russian Transfer-Case Auxiliary Suspension logic, these joints must provide enough flexibility to accommodate chassis flex while remaining rigid enough to hold the driveline angle. The “469” suffix suggests a robust design standard, likely involving spherical bearings or high-density rubber bushings capable of surviving the grit and ice of Siberian mining roads.

The “55R” designation on the rods within the FAW Russian Transfer-Case Auxiliary Suspension indicates a material specification tailored for the Russian market. Standard steel rods can become brittle at extreme low temperatures, snapping under shock loads. The FAW Russian Transfer-Case Auxiliary Suspension utilizes high-strength low-alloy (HSLA) steel that retains ductility at -40°C. This ensures that when the truck hits a frozen rut under full load, the rods absorb the shock rather than fracturing, protecting the expensive transfer case housing from damage.

Anchoring Logic: The Multi-Point Bracket System

The pull rods of the FAW Russian Transfer-Case Auxiliary Suspension must be anchored to immoveable points on the chassis and the transfer case. This is achieved through a complex bracketry system including the Left Bracket (Part No. 1801031-55R), Right Bracket (Part No. 1801032-55R), Left Upper Bracket (Part No. 1801037-733), and Right Upper Bracket (Part No. 1801038-733). This multi-point geometry creates a triangulation effect, locking the transfer case in three-dimensional space via the FAW Russian Transfer-Case Auxiliary Suspension.

The FAW Russian Transfer-Case Auxiliary Suspension design places these brackets strategically to counteract specific force vectors. The lower brackets handle the primary torque reaction, while the upper brackets assist in stabilizing vertical and lateral movements. This distribution of labor reduces the stress on any single mounting point, preventing fatigue cracks in the chassis rails. The robust engineering of the FAW Russian Transfer-Case Auxiliary Suspension prevents the “axle wrap” effect that can snap U-joints under heavy acceleration.

To ensure precise alignment, the FAW Russian Transfer-Case Auxiliary Suspension incorporates Spacer Block (Part No. 1806039-55R). These spacers allow for the adjustment of the transfer case angle. Correct driveline angles are essential for the longevity of the universal joints. If the transfer case is misaligned, it generates destructive vibrations that can shatter seals and bearings. The FAW Russian Transfer-Case Auxiliary Suspension provides the adjustability needed to maintain factory specs even as the truck ages and the suspension settles.

Damping Logic: Bushings and Washers

Direct metal-on-metal contact in a suspension system leads to noise, wear, and fatigue. The FAW Russian Transfer-Case Auxiliary Suspension employs Bushing (Part No. 1801051-469) and Washer (Part No. 1801052-469) to isolate the pull rods from the brackets. These components act as the flexible interface within the FAW Russian Transfer-Case Auxiliary Suspension, absorbing high-frequency vibrations from the gear mesh and low-frequency shocks from the road surface.

The material composition of these bushings is critical for the Russian market. Standard rubber bushings freeze solid in the Arctic, losing their damping ability and transmitting shock loads directly to the brackets. The FAW Russian Transfer-Case Auxiliary Suspension utilizes a specialized elastomer or polyurethane compound that remains compliant at low temperatures. This ensures that the FAW Russian Transfer-Case Auxiliary Suspension system continues to filter out vibration, protecting the transfer case housing from stress fractures.

The inclusion of the Snap Ring – Steering Pull Rod (Part No. 3003056-1H) in this assembly suggests a secondary retention mechanism for the rod ends or boots. While originally named for steering applications, its presence in the FAW Russian Transfer-Case Auxiliary Suspension highlights the modular heavy-duty design philosophy of FAW. These rings ensure that the protective boots or bushing retainers stay in place, keeping contaminants out of the pivot points—a vital function in the muddy environment of a quarry.

Security Logic: High-Tensile Fasteners

The integrity of the FAW Russian Transfer-Case Auxiliary Suspension depends entirely on its fasteners. The assembly uses a mix of Hexagon Head Bolt (Part No. CQ1501635 and CQ1501460) and Hexagon Flange Bolt Coarse Shank (Part No. Q1841295 and Q1841455). The use of coarse shank bolts is a deliberate choice for the FAW Russian Transfer-Case Auxiliary Suspension. Coarse threads provide deeper engagement and better resistance to stripping under the high shear loads experienced by the suspension brackets.

To prevent loosening under vibration, the FAW Russian Transfer-Case Auxiliary Suspension employs Hexagon Head Flange Locking Nut (Part No. CQ32612) and standard Hexagon Nut (Part No. CQ34014) paired with Spring Washer (Part No. Q40314 and Q40316). The flange locking nuts feature serrated faces that bite into the bracket metal, providing a mechanical lock. The spring washers act as active tensioners, compensating for the thermal contraction of the bolts in the extreme cold, ensuring the FAW Russian Transfer-Case Auxiliary Suspension joint remains tight.

The FAW Russian Transfer-Case Auxiliary Suspension specifies high-grade steel for these fasteners (likely Class 10.9 or 12.9) to handle the immense clamping forces required. Furthermore, they are treated with corrosion-resistant coatings to survive the saline slush of Russian winter roads. Using inferior bolts during a repair can lead to catastrophic suspension failure, allowing the transfer case to break loose and destroy the driveline. The reliability of the FAW Russian Transfer-Case Auxiliary Suspension is non-negotiable for vehicle safety.

Component Breakdown: 122. Transfer Case Auxiliary Suspension Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | 1801031-55R | Left Bracket – Transfer Case Auxiliary Pull Rod | 1 |

| 2 | 1801032-55R | Right Bracket – Transfer Case Auxiliary Pull Rod | 1 |

| 3 | 1801037-733 | Left Upper Bracket – Transfer Case Auxiliary Pull Rod | 1 |

| 4 | 1801038-733 | Right Upper Bracket – Transfer Case Auxiliary Pull Rod | 1 |

| 5 | 1801051-469 | Bushing – Transfer Case Auxiliary Pull Rod | 4 |

| 6 | 1801052-469 | Washer – Transfer Case Auxiliary Pull Rod | 8 |

| 7 | 1801055-469 | Front Joint Assembly | 2 |

| 8 | 1801060-469 | Rear Joint Assembly | 2 |

| 9 | 1806039-55R | Spacer Block | 3 |

| 10 | 1806054-55R | Left Auxiliary Pull Rod – Transfer Case | 1 |

| 11 | 1806064-55R | Right Auxiliary Pull Rod – Transfer Case | 1 |

| 12 | 3003056-1H | Snap Ring – Steering Pull Rod | 4 |

| 13 | CQ1501460 | Hexagon Head Bolt | 4 |

| 14 | CQ1501635 | Hexagon Head Bolt | 8 |

| 15 | CQ32612 | Hexagon Head Flange Locking Nut | 4 |

| 16 | CQ34014 | Hexagon Nut | 10 |

| 17 | Q1841295 | Hexagon Flange Bolt Coarse Shank (Standard) | 4 |

| 18 | Q1841455 | Hexagon Flange Bolt Coarse Shank (Standard) | 6 |

| 19 | Q40314 | Spring Washer | 10 |

| 20 | Q40316 | Spring Washer | 8 |

Conclusion: The Torque Management Solution

The FAW Russian Transfer-Case Auxiliary Suspension assembly is a vital component in the off-road capability of the CA3250P66K24L1TE5Z dump truck. By managing the reaction torque of the drivetrain, it protects the expensive transfer case and transmission from structural failure. The strategic use of cold-resistant materials, multi-point mounting brackets, and secure fasteners ensures that the FAW Russian Transfer-Case Auxiliary Suspension remains operational even in the harshest Siberian conditions.

For fleet owners, maintaining this assembly is essential for long-term reliability. A broken pull rod or a worn bushing in the FAW Russian Transfer-Case Auxiliary Suspension can lead to driveline vibration and accelerated wear of universal joints. By regularly inspecting and replacing worn components with genuine FAW parts, operators can ensure that their trucks continue to deliver the robust performance required for heavy-duty mining and construction operations.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.