Suspensión auxiliar de caja de transferencia rusa FAW: Ingeniería 20 Enlaces estratégicos para una estabilidad absoluta de la línea motriz

El Suspensión auxiliar de caja de transferencia rusa FAW El conjunto lógico sirve como red estabilizadora crítica para el camión volquete CA3250P66K24L1TE5Z.. Mientras que los soportes principales soportan el peso vertical, Este sistema auxiliar gestiona el intenso par de reacción y las fuerzas longitudinales generadas durante el funcionamiento con tracción total.. En el terreno implacable de la Federación Rusa, el Suspensión auxiliar de caja de transferencia rusa FAW evita que la caja de transferencia se desalinee, asegurando que la potencia se entregue suavemente a los ejes incluso cuando la temperatura ambiente cae a -40°C.

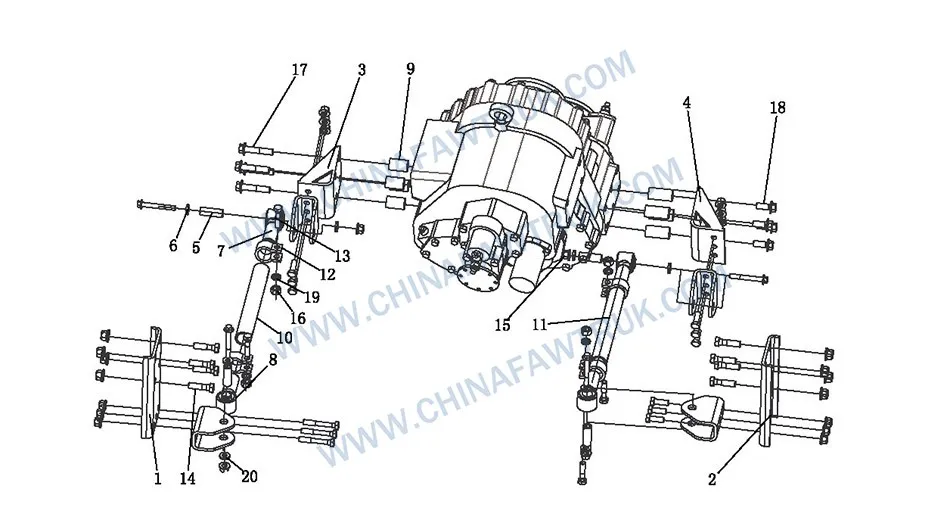

Conjunto de suspensión auxiliar de caja de transferencia rusa FAW

Dinámica de estabilización: Las varillas de tracción auxiliares

Los componentes definitorios de la Suspensión auxiliar de caja de transferencia rusa FAW son las varillas de tiro: Varilla de tracción auxiliar izquierda (Número de pieza. 1806054-55R) y Varilla de tracción auxiliar derecha (Número de pieza. 1806064-55R). Estas barras de acero de alta resistencia actúan como brazos de torsión.. Cuando la caja de transferencia se acopla al eje delantero o al rango bajo, Una inmensa fuerza de rotación intenta torcer la caja dentro de los rieles del chasis.. El Suspensión auxiliar de caja de transferencia rusa FAW utiliza estas varillas para absorber esa energía, convertir un par de rotación peligroso en fuerzas de tensión y compresión lineales manejables.

Cruciales para esta función son las articulaciones: Asamblea conjunta delantera (Número de pieza. 1801055-469) y Conjunto de junta trasera (Número de pieza. 1801060-469). En el Suspensión auxiliar de caja de transferencia rusa FAW lógica, Estas juntas deben proporcionar suficiente flexibilidad para adaptarse a la flexión del chasis y al mismo tiempo permanecer lo suficientemente rígidas para mantener el ángulo de la línea motriz.. El “469” el sufijo sugiere un estándar de diseño robusto, Probablemente se trate de cojinetes esféricos o casquillos de goma de alta densidad capaces de sobrevivir a la arena y el hielo de las carreteras mineras de Siberia..

El “55R” designación en las varillas dentro del Suspensión auxiliar de caja de transferencia rusa FAW indica una especificación de material diseñada para el mercado ruso. Las varillas de acero estándar pueden volverse quebradizas a temperaturas extremadamente bajas, romperse bajo cargas de choque. El Suspensión auxiliar de caja de transferencia rusa FAW utiliza baja aleación de alta resistencia (HSLA) acero que conserva la ductilidad a -40°C. Esto garantiza que cuando el camión llegue a una rodera congelada con carga completa, Las varillas absorben el impacto en lugar de fracturarse., Proteger la costosa carcasa de la caja de transferencia contra daños..

Lógica de anclaje: El sistema de soporte multipunto

Las varillas de tracción del Suspensión auxiliar de caja de transferencia rusa FAW Deben estar anclados a puntos inamovibles del chasis y de la caja de transferencia.. Esto se logra mediante un complejo sistema de brackets que incluye el Soporte izquierdo (Número de pieza. 1801031-55R), Soporte derecho (Número de pieza. 1801032-55R), Soporte superior izquierdo (Número de pieza. 1801037-733), y Soporte superior derecho (Número de pieza. 1801038-733). Esta geometría multipunto crea un efecto de triangulación., bloquear la caja de transferencia en el espacio tridimensional a través del Suspensión auxiliar de caja de transferencia rusa FAW.

El Suspensión auxiliar de caja de transferencia rusa FAW El diseño coloca estos soportes estratégicamente para contrarrestar vectores de fuerza específicos.. Los soportes inferiores manejan la reacción de torsión primaria., mientras que los soportes superiores ayudan a estabilizar los movimientos verticales y laterales. Esta distribución del trabajo reduce la tensión en cualquier punto de montaje., Prevención de grietas por fatiga en los rieles del chasis.. La robusta ingeniería del Suspensión auxiliar de caja de transferencia rusa FAW previene el “envoltura del eje” efecto que puede romper las juntas universales bajo una fuerte aceleración.

Para garantizar una alineación precisa, el Suspensión auxiliar de caja de transferencia rusa FAW incorpora Bloque espaciador (Número de pieza. 1806039-55R). Estos espaciadores permiten el ajuste del ángulo de la caja de transferencia.. Los ángulos correctos de la línea motriz son esenciales para la longevidad de las juntas universales. Si la caja de transferencia está desalineada, Genera vibraciones destructivas que pueden romper sellos y cojinetes.. El Suspensión auxiliar de caja de transferencia rusa FAW Proporciona la capacidad de ajuste necesaria para mantener las especificaciones de fábrica incluso cuando el camión envejece y la suspensión se asienta..

Lógica de amortiguación: Bujes y Arandelas

El contacto directo de metal con metal en un sistema de suspensión genera ruido, tener puesto, y fatiga. El Suspensión auxiliar de caja de transferencia rusa FAW emplea Cojinete (Número de pieza. 1801051-469) y Lavadora (Número de pieza. 1801052-469) para aislar las varillas de tracción de los soportes. Estos componentes actúan como interfaz flexible dentro del Suspensión auxiliar de caja de transferencia rusa FAW, Absorber vibraciones de alta frecuencia del engranaje y golpes de baja frecuencia de la superficie de la carretera..

La composición del material de estos casquillos es fundamental para el mercado ruso.. Los casquillos de goma estándar se congelan en el Ártico, perdiendo su capacidad de amortiguación y transmitiendo cargas de impacto directamente a los soportes. El Suspensión auxiliar de caja de transferencia rusa FAW Utiliza un compuesto de elastómero o poliuretano especializado que sigue siendo compatible a bajas temperaturas.. Esto asegura que el Suspensión auxiliar de caja de transferencia rusa FAW El sistema continúa filtrando las vibraciones., Proteger la carcasa de la caja de transferencia de fracturas por tensión..

La inclusión de la Anillo – Varilla de tracción de dirección (Número de pieza. 3003056-1h) En este conjunto se sugiere un mecanismo de retención secundario para los extremos de las varillas o botas.. Aunque originalmente recibió su nombre para aplicaciones de dirección, su presencia en el Suspensión auxiliar de caja de transferencia rusa FAW destaca la filosofía de diseño modular de alta resistencia de FAW. Estos anillos aseguran que las botas protectoras o los retenedores de casquillos permanezcan en su lugar., Mantener los contaminantes fuera de los puntos de pivote, una función vital en el ambiente fangoso de una cantera..

Lógica de seguridad: Sujetadores de alta resistencia

La integridad de la Suspensión auxiliar de caja de transferencia rusa FAW depende enteramente de sus sujetadores. El montaje utiliza una mezcla de Perno de cabeza hexagonal (Número de pieza. CQ1501635 y CQ1501460) y Perno de brida hexagonal Vástago grueso (Número de pieza. Q1841295 y Q1841455). El uso de pernos de mango grueso es una elección deliberada para Suspensión auxiliar de caja de transferencia rusa FAW. Las roscas gruesas proporcionan un acoplamiento más profundo y una mejor resistencia al desgarro bajo las altas cargas de corte que experimentan los soportes de suspensión..

Para evitar que se afloje bajo vibración, el Suspensión auxiliar de caja de transferencia rusa FAW emplea Tuerca de bloqueo de brida de cabeza hexagonal (Número de pieza. CQ32612) y estándar Tuerca hexagonal (Número de pieza. CQ34014) emparejado con Arandela de resorte (Número de pieza. Q40314 y Q40316). Las tuercas de seguridad con brida tienen caras dentadas que se clavan en el metal del soporte., proporcionando una cerradura mecánica. Las arandelas elásticas actúan como tensores activos., Compensar la contracción térmica de los pernos en condiciones de frío extremo., asegurando el Suspensión auxiliar de caja de transferencia rusa FAW la articulación permanece apretada.

El Suspensión auxiliar de caja de transferencia rusa FAW especifica acero de alta calidad para estos sujetadores (clase probable 10.9 o 12.9) para manejar las inmensas fuerzas de sujeción requeridas. Además, Están tratados con revestimientos resistentes a la corrosión para sobrevivir al aguanieve salino de las carreteras invernales rusas.. El uso de pernos inferiores durante una reparación puede provocar una falla catastrófica en la suspensión, permitiendo que la caja de transferencia se suelte y destruya la línea motriz. La confiabilidad del Suspensión auxiliar de caja de transferencia rusa FAW No es negociable para la seguridad del vehículo..

Desglose de componentes: 122. Conjunto lógico de suspensión auxiliar de caja de transferencia

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 1801031-55R | Soporte izquierdo – Varilla de tracción auxiliar de caja de transferencia | 1 |

| 2 | 1801032-55R | Soporte derecho – Varilla de tracción auxiliar de caja de transferencia | 1 |

| 3 | 1801037-733 | Soporte superior izquierdo – Varilla de tracción auxiliar de caja de transferencia | 1 |

| 4 | 1801038-733 | Soporte superior derecho – Varilla de tracción auxiliar de caja de transferencia | 1 |

| 5 | 1801051-469 | Cojinete – Varilla de tracción auxiliar de caja de transferencia | 4 |

| 6 | 1801052-469 | Lavadora – Varilla de tracción auxiliar de caja de transferencia | 8 |

| 7 | 1801055-469 | Asamblea conjunta delantera | 2 |

| 8 | 1801060-469 | Conjunto de junta trasera | 2 |

| 9 | 1806039-55R | Bloque espaciador | 3 |

| 10 | 1806054-55R | Varilla de tracción auxiliar izquierda – Caja de transferencia | 1 |

| 11 | 1806064-55R | Varilla de tracción auxiliar derecha – Caja de transferencia | 1 |

| 12 | 3003056-1h | Anillo – Varilla de tracción de dirección | 4 |

| 13 | CQ1501460 | Perno de cabeza hexagonal | 4 |

| 14 | CQ1501635 | Perno de cabeza hexagonal | 8 |

| 15 | CQ32612 | Tuerca de bloqueo de brida de cabeza hexagonal | 4 |

| 16 | CQ34014 | Tuerca hexagonal | 10 |

| 17 | Q1841295 | Perno de brida hexagonal Vástago grueso (Estándar) | 4 |

| 18 | Q1841455 | Perno de brida hexagonal Vástago grueso (Estándar) | 6 |

| 19 | Q40314 | Arandela de resorte | 10 |

| 20 | Q40316 | Arandela de resorte | 8 |

Conclusión: La solución de gestión del par

El Suspensión auxiliar de caja de transferencia rusa FAW El ensamblaje es un componente vital en la capacidad todoterreno del camión volquete CA3250P66K24L1TE5Z.. Gestionando el par de reacción de la transmisión., Protege la costosa caja de transferencia y la transmisión de fallas estructurales.. El uso estratégico de materiales resistentes al frío, soportes de montaje multipunto, y sujetadores seguros aseguran que el Suspensión auxiliar de caja de transferencia rusa FAW permanece operativo incluso en las condiciones más duras de Siberia.

Para propietarios de flotas, El mantenimiento de este conjunto es esencial para la confiabilidad a largo plazo.. Una varilla de tracción rota o un casquillo desgastado en el Suspensión auxiliar de caja de transferencia rusa FAW puede provocar vibraciones en la línea motriz y desgaste acelerado de las juntas universales. Inspeccionando y reemplazando periódicamente los componentes desgastados con piezas originales FAW, Los operadores pueden asegurarse de que sus camiones sigan brindando el sólido rendimiento requerido para operaciones pesadas de minería y construcción..

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.