FAW Russian Rear Guard: Deploying 45 Structural Components for Ultimate Rear-End Impact Safety

The FAW Russian Rear Guard logic assembly serves as the final defensive perimeter for the CA3250P66K24L1TE5Z heavy-duty dump truck. Engineered to meet stringent Rear Underrun Protection Device (RUPD) standards, this system is designed to prevent smaller passenger vehicles from sliding beneath the chassis during collisions. Constructed from specialized low-temperature alloy steel, the FAW Russian Rear Guard maintains its structural ductility even in the brittle -50°C environment of the Siberian winter. This guide analyzes the energy-absorbing brackets, the rigid cross-beam architecture, and the high-tensile fastening systems that ensure safety and compliance.

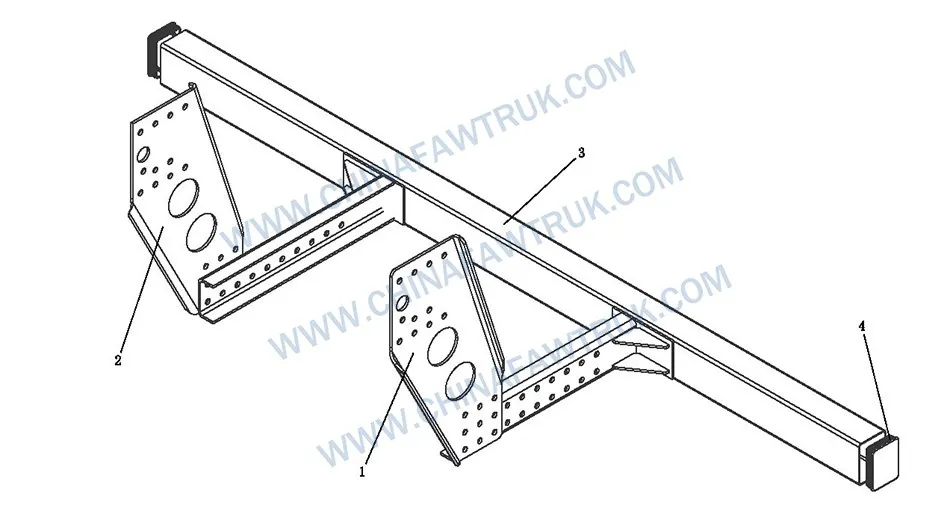

FAW Russian Rear Guard

Bracket Architecture and Energy Absorption

The structural integrity of the FAW Russian Rear Guard relies heavily on its mounting system, specifically the Rear Protection Left Bracket (Part No. 2809211-54S) and the Rear Protection Right Bracket (Part No. 2809212-54S). These components act as the interface between the rigid chassis frame and the impact beam. In the “Russian Spec” configuration, these brackets are manufactured from “54S” grade steel. This metallurgy is chosen specifically for its high yield strength and improved impact toughness at sub-zero temperatures. Standard structural steel can become brittle when frozen, snapping under load; however, the FAW Russian Rear Guard brackets are designed to deform plastically, absorbing kinetic energy and reducing the deceleration forces transferred to the truck chassis.

The geometry of these brackets is engineered to position the cross beam at the precise height required by international safety regulations (typically 550mm from the ground). This positioning is critical for engaging the crumple zones of impacting passenger cars. The connection to the chassis frame is secured using the Hexagon Head Flange Bolt (Part No. Q1841455T). Eight of these heavy-duty bolts are utilized to clamp the brackets to the frame rails. The flange head design distributes the clamping load over a wide area, preventing the bolt head from embedding into the bracket steel, which ensures that the torque tension remains consistent even after years of thermal cycling.

Furthermore, the FAW Russian Rear Guard system employs the Hexagon Flange Lock Nut (Part No. CQ32614) for these connections. These nuts feature a prevailing torque feature that prevents loosening due to the severe vibration inherent in off-road dump trucking. In the context of the FAW Russian Rear Guard, a loose bracket would not only fail safety inspections but could lead to the guard detaching during operation. The robust fastening logic ensures that the brackets remain an immovable foundation for the entire protective system.

The Impact Beam: Structural Rigidity

Spanning the width of the vehicle is the Rear Protection Cross Beam Assembly (Part No. 2809220-54S). This is the primary impact member of the FAW Russian Rear Guard. Fabricated from a closed-section steel profile, this beam offers exceptional resistance to bending and torsional forces. The “54S” material specification ensures that the beam retains sufficient ductility to bend without cracking when subjected to a high-speed rear impact. This controlled deformation is a key safety feature, preventing the FAW Russian Rear Guard from acting as a rigid wall that could cause fatal deceleration forces for the occupants of the impacting vehicle.

The mounting of the cross beam to the vertical brackets utilizes a specific fastening strategy involving 12 units of the Hexagon Flange Bolt (Part No. Q1841440T). These bolts feature a “Coarse Shank” (Standard Type) design. The coarse thread profile provides superior resistance to stripping and fatigue compared to fine threads, especially in soft or ductile materials. In the FAW Russian Rear Guard assembly, this robustness is vital because the beam is often subjected to vertical loads when the truck bottoms out in deep ruts or when the guard is inadvertently used as a push-bar by bulldozers in the pit.

The ends of the cross beam are sealed with the Rear Protection Cross Beam End Cover (Part No. 2809213-60N). While seemingly minor, these covers play a crucial role in the longevity of the FAW Russian Rear Guard. They prevent road salt, mud, and acidic slurry from entering the hollow beam. Without these covers, the beam would corrode from the inside out, silently compromising its structural integrity. The “60N” material indicates a polymer or composite that remains flexible in the cold, maintaining a tight seal against the steel beam even when temperatures drop to -50°C.

Fastening Logic and Corrosion Resistance

The reliability of the FAW Russian Rear Guard is ultimately defined by the quality of its fasteners. The assembly uses a total of 20 high-tensile flange nuts (Part No. CQ32614) to secure both the brackets and the cross beam. The flange design eliminates the need for separate flat washers, reducing the parts count and minimizing the risk of assembly errors. This integrated washer face also provides a larger surface area to span over the mounting holes, which is particularly important for the slotted holes often used in the FAW Russian Rear Guard brackets to allow for alignment adjustments.

Corrosion is the arch-enemy of chassis components in Russia, where magnesium chloride and other aggressive de-icers are used liberally. The bolts and nuts used in the FAW Russian Rear Guard undergo a specialized zinc-flake or Dacromet coating process. This sacrificial coating protects the steel fastener from rust even if the surface is scratched during installation. Furthermore, the main steel components—the brackets and the beam—are treated with a heavy-duty chassis paint that bonds molecularly with the steel, preventing the underfilm corrosion that plagues inferior aftermarket parts.

Maintenance teams must pay close attention to the torque settings of these fasteners. Due to the settling of paint layers and the relaxation of the bolted joints, the FAW Russian Rear Guard bolts should be re-torqued after the first 5,000 km of service. Neglecting this step can lead to “bolt walk,” where the fasteners vibrate loose, leading to a rattling guard and eventual structural failure. The design of the FAW Russian Rear Guard facilitates easy access to all bolt heads, encouraging regular inspection and maintenance.

Component Breakdown: Rear Protection Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | 2809211-54S | Rear Protection Left Bracket | 1 |

| 2 | 2809212-54S | Rear Protection Right Bracket | 1 |

| – | CQ32614 | Hexagon Flange Lock Nut | 8 |

| – | Q1841455T | Hexagon Head Flange Bolt | 8 |

| 3 | 2809220-54S | Rear Protection Cross Beam Assembly | 1 |

| – | CQ32614 | Hexagon Flange Lock Nut | 12 |

| – | Q1841440T | Hexagon Flange Bolt (Coarse Shank) | 12 |

| 4 | 2809213-60N | Rear Protection Cross Beam End Cover | 2 |

Conclusion: A Vital Safety Asset

The FAW Russian Rear Guard is more than a simple bumper; it is a legally mandated safety system that protects other road users and the rear structure of the truck itself. By combining “54S” low-temperature steel with a robust, vibration-resistant fastening architecture, FAW has created a component that delivers consistent performance in the most demanding operational theaters. For fleet managers, the integrity of the FAW Russian Rear Guard is a direct reflection of their commitment to safety and compliance.

Regular inspection of the cross beam for deformation and checking the torque on the mounting bolts are simple yet effective ways to ensure the longevity of this system. Using only genuine FAW replacement parts for the FAW Russian Rear Guard guarantees that the steel metallurgy matches the original design specifications, maintaining the crucial balance between rigidity and energy absorption that keeps the roads safe for everyone.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.