FAW Russian Rear-Axle Suspension Bracket: Anchoring 15 Key Components for Heavy-Haul Stability

The FAW Russian Rear-Axle Suspension Bracket logic assembly is the foundational connection point that secures the drive axles to the balance suspension components of the CA3250P66K24L1TE5Z dump truck. This complex structure must withstand the full vertical weight of the payload while simultaneously resisting the rotational torque and longitudinal thrust generated by the 6×6 drivetrain. Engineered with “55R” and “64W” arctic-grade materials, the FAW Russian Rear-Axle Suspension Bracket ensures precise axle location, preventing misalignment and guaranteeing power delivery across frozen, unstable terrain.

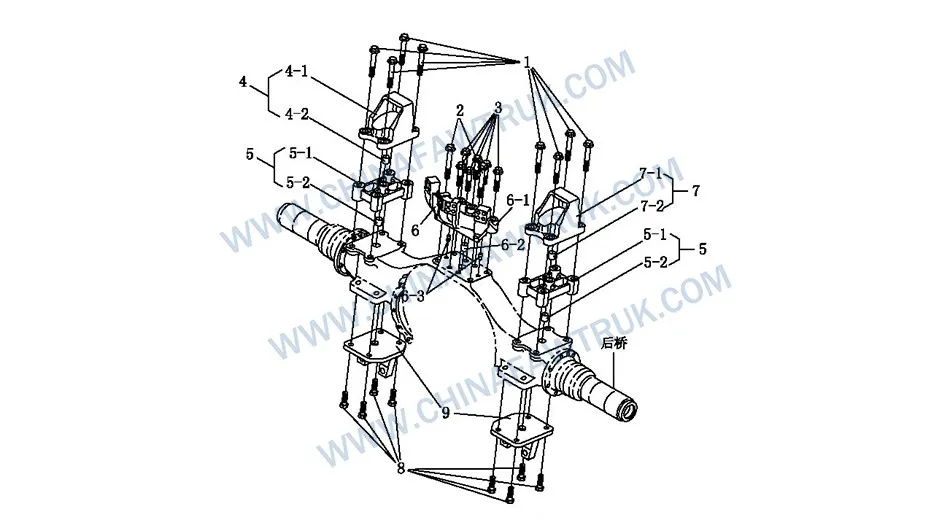

FAW Russian Rear-Axle Suspension Bracket

The Leaf Spring Seat and Damping Interface

The load path begins at the **Rear Leaf Spring Seat Assembly** (Part No. 2912445-55R / 2912450-55R / 2912442-55R). This heavy steel casting sits directly on the axle housing, providing the foundation for the leaf spring pack. The FAW Russian Rear-Axle Suspension Bracket uses a dual design (e.g., 2912441-55R for left side, 2912442-55R for right side) to ensure proper fitment over the axle. The seat must transfer the entire payload from the springs into the axle housing without allowing any rotational movement (axle wrap), which is resisted by the sheer clamping force of the U-bolts (not detailed here, but implied).

Integrated into this seat assembly are specialized damping elements. The Cushion & Locating Pin Assembly (Part No. 2912405-55R) utilizes a **Cushion – Rear Leaf Spring Seat** (Part No. 2912402-55R) that isolates high-frequency road shock from the metal bracket. This cushion material is crucial for the FAW Russian Rear-Axle Suspension Bracket; it must retain elasticity in sub-zero temperatures. The assembly also includes a **Locating Pin** (Part No. 2912401-A2E) that indexes the spring pack to the seat, preventing longitudinal shift during braking.

The mounting of the reaction rods is tied directly into the FAW Russian Rear-Axle Suspension Bracket. The **Rear Axle Lower Bracket Welding Assembly** (Part No. 2919310-A7E) provides the lower anchor points for the reaction rods. This heavily reinforced, welded structure ensures that the immense torque transferred through the axle during acceleration does not bend or shear the mounting tabs. The strength of the FAW Russian Rear-Axle Suspension Bracket in this zone is paramount for maintaining the precise pinion angle of the rear differential.

Reaction Rod Anchor Points and Pin Logic

The upper control arms are secured to the axle housing via the **Reaction Rod Upper Bracket with Locating Pin Assy – Rear Axle** (Part No. 2919220A64W). This casting serves as the fixed upper pivot point. It features mounting eyes that house the **Elastic Cylindrical Pin** (Part No. 2919201-A2E / 2919202-A2E). These pins are shear pins that must resist the full thrust of the truck’s forward movement. The “A2E” specification implies a hardened, precision-ground steel designed for low-friction articulation with the rubber bushings of the reaction rod.

The design of the FAW Russian Rear-Axle Suspension Bracket utilizes these **Elastic Cylindrical Pins** to allow controlled angular movement of the reaction rod while preventing longitudinal shift. The elasticity of the pins themselves helps absorb some of the high-frequency vibration, preventing it from being transmitted directly into the mounting bracket. This protects the **Upper Reaction Rod Bracket – Rear Axle** (Part No. 2919212A64W) from premature fatigue cracking, a common failure mode in non-articulated suspension brackets.

The mounting process requires precise alignment. The pins and bushings must be installed without bending or over-compressing them. The FAW Russian Rear-Axle Suspension Bracket, particularly the upper anchor points, dictates the pinion angle of the rear axle. Any wear or damage to the mounting holes in the **Rear Axle Lower Bracket Welding Assembly** (Part No. 2919310-A7E) will alter the axle geometry, leading to driveshaft vibration and accelerated U-joint wear.

Fastening and Assembly Integrity

The numerous components of the FAW Russian Rear-Axle Suspension Bracket assembly are clamped together by a variety of high-strength bolts. The assembly utilizes **Hexagon Head Bolt** (Part No. CQ15120130T) and **Hexagon Head Bolt** (Part No. CQ1512060T) for general bracket mounting. These bolts are Grade 10.9 or higher, required to handle the shear and tensile loads. Furthermore, the specialized **Hexagon Flange Bolt (Coarse Shank)** (Part No. Q1842050TF38K) and **Hexagon Flange Bolt (Coarse Shank)** (Part No. Q1842095TF38K) are used for securing the most critical structural interfaces.

The bolts feature specialized anti-corrosion coatings (indicated by ‘T’ or ‘TF38K’ suffixes) to resist the highly corrosive road salt environment of the Russian winter. This ensures that the fasteners of the FAW Russian Rear-Axle Suspension Bracket can be removed for service even after years of exposure. The total number of bolts and pins ensures a highly redundant mounting system.

The welding quality of the **Rear Axle Lower Bracket Welding Assembly** (Part No. 2919310-A7E) is paramount. This assembly, like many in the FAW Russian Rear-Axle Suspension Bracket system, relies on robust, continuous welds that are inspected for defects. In the cold, thermal contraction creates tension; a flawed weld will crack, leading to immediate structural failure of the torque rod anchor point. FAW specifies low-hydrogen welding processes to maximize weld integrity.

Maintenance and Cold-Weather Serviceability

Maintaining the FAW Russian Rear-Axle Suspension Bracket requires proactive inspection. The primary failure mode is wear around the pin holes or stress cracks in the bracket castings. Visual inspection of the **Rear Leaf Spring Seat** (Part No. 2912441-55R / 2912442-55R) for signs of slippage (rust trails) or deformation is mandatory. Any evidence of movement indicates that the U-bolts are loose, risking catastrophic spring failure.

The **Cushion** (Part No. 2912402-55R) should be checked for wear and deterioration. If the cushion is worn, the metal components of the FAW Russian Rear-Axle Suspension Bracket will pound against each other, accelerating bracket fatigue. The **Elastic Cylindrical Pins** (Part No. 2919201-A2E) should be replaced during any major axle service to ensure the pivot points remain tight and vibration-free.

When replacing components, only genuine FAW parts should be used. The “55R” and “64W” specifications are integral to the cold-weather performance of the FAW Russian Rear-Axle Suspension Bracket. Aftermarket substitutes often use standard steel that lacks the necessary low-temperature impact toughness, leading to premature failure when the truck is needed most.

The complexity of the FAW Russian Rear-Axle Suspension Bracket demands professional service. Correctly installing the leaf spring seats and setting the alignment of the reaction rod brackets ensures the truck’s driveline geometry is preserved. This meticulous attention to detail is what guarantees the long-term reliability of the CA3250P66K24L1TE5Z in the heavy-haul segment.

Component Breakdown: Rear Axle Suspension Bracket Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | CQ15120130T | Hexagon Head Bolt | 8 |

| 2 | Q1842050TF38K | Hexagon Flange Bolt (Coarse Shank) | 6 |

| 3 | Q1842095TF38K | Hexagon Flange Bolt (Coarse Shank) | 2 |

| 4 | 2912445-55R | Rear Leaf Spring Seat Assembly | 1 |

| 5 | 2912405-55R | Cushion & Locating Pin Assembly – Rear Leaf Spring Seat | 2 |

| 6 | 2919220A64W | Reaction Rod Upper Bracket with Locating Pin Assy – Rear Axle | 1 |

| 7 | 2912450-55R | Rear Leaf Spring Seat Assembly | 1 |

| 8 | CQ1512060T | Hexagon Head Bolt | 8 |

| 9 | 2919310-A7E | Rear Axle Lower Bracket Welding Assembly | 2 |

| 4-1 | 2912441-55R | Rear Leaf Spring Seat – Middle Left/Rear Right | 1 |

| 4-2 | 2919201-A2E | Elastic Cylindrical Pin | 1 |

| 5-1 | 2912402-55R | Cushion – Rear Leaf Spring Seat | 2 |

| 5-2 | 2912401-A2E | Elastic Cylindrical Pin | 2 |

| 6-1 | 2919212A64W | Upper Reaction Rod Bracket – Rear Axle | 1 |

| 6-2 | 2919201-A2E | Elastic Cylindrical Pin | 1 |

| 7-1 | 2912442-55R | Rear Leaf Spring Seat – Middle Right/Rear Left | 1 |

| 7-2 | 2919201-A2E | Elastic Cylindrical Pin | 1 |

Conclusion: Structural Reliability Guaranteed

The FAW Russian Rear-Axle Suspension Bracket assembly is the definitive anchor for the rear suspension, guaranteeing the structural integrity of the drive axles under extreme loads. By integrating heavy-duty steel castings with shock-absorbing cushions and high-tensile fasteners, the system ensures the CA3250P66K24L1TE5Z performs reliably. The “55R” and “64W” component specifications are key to its arctic endurance.

For fleet managers, proactive maintenance—checking for wear in the cushions and ensuring the bolts are torqued to spec—is essential for vehicle uptime. Utilizing genuine FAW parts for the FAW Russian Rear-Axle Suspension Bracket preserves the precise alignment and safety standards engineered for the harsh environment of the Russian North.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.