FAW Russian Front Combination Lamp Logic: Illuminating 10 Precision Elements to Pierce the Arctic Night

The FAW Russian Front Combination Lamp logic assembly is the primary visual guidance system for the CA3250P66K24L1TE5Z dump truck. In the mining sectors of the Russian North, where winter darkness prevails for 20 hours a day and blizzard conditions reduce visibility to near zero, the performance of the FAW Russian Front Combination Lamp is a matter of life and death. This assembly integrates high-intensity illumination, signaling, and position markers into a single, ruggedized housing designed to withstand impact from ice and stone while maintaining hermetic sealing against freezing moisture.

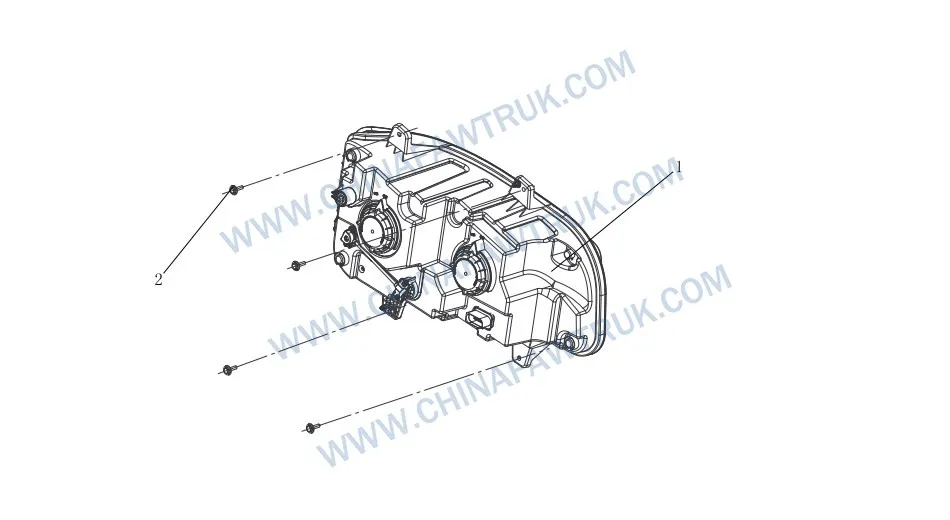

FAW Russian Front Combination Lamp

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3711015A91W-C00 | Left Front Combination Lamp Assembly | 1 |

| 1 | 3711020A91W-C00 | Right Front Combination Lamp Assembly | 1 |

| 2 | CQ1460625 | Combination Bolt | 8 |

Optical Engineering for Polar Conditions

The design philosophy behind the FAW Russian Front Combination Lamp prioritizes two conflicting requirements: high luminous output and thermal management for ice melting. In modern automotive design, LEDs are common, but the FAW Russian Front Combination Lamp typically utilizes high-wattage halogen elements for the primary beams. This is a strategic choice for the Arctic; the infrared heat generated by the halogen bulb warms the polycarbonate lens, preventing the accumulation of snow and ice while driving. Without this passive heating effect, a cold LED lens would quickly become obscured by freezing slush, rendering the FAW Russian Front Combination Lamp useless in a blizzard.

The optical geometry of the Left Front Combination Lamp Assembly (Part No. 3711015A91W-C00) is specifically tuned for right-hand traffic patterns found in Russia. The low-beam cut-off is sharp and asymmetrical, illuminating the road shoulder and signage without blinding oncoming traffic on narrow, snow-banked roads. The reflector surfaces within the FAW Russian Front Combination Lamp are vacuum-metallized with a high-purity aluminum coating, protected by a silica topcoat to prevent oxidation and yellowing over years of use. This ensures that the photometric performance remains compliant with ECE regulations throughout the vehicle’s lifespan.

Furthermore, the “91W-C00” designation implies a heavy-duty filament construction. Dump trucks generate significant vibration, which can cause standard filaments to shatter. The bulbs used in the FAW Russian Front Combination Lamp feature reinforced support bridges to stabilize the tungsten coil. This vibration resistance is critical for maintaining illumination on the washboard surfaces of mining haul roads. By combining thermal de-icing capability with shock-resistant internals, the FAW Russian Front Combination Lamp provides the reliable visibility needed for safe 24-hour operations.

Materials and Environmental Sealing

The housing of the FAW Russian Front Combination Lamp is molded from an impact-modified ABS/Polycarbonate blend. This material is selected for its ductility at low temperatures. Standard plastics become brittle and shatter like glass when hit by a rock at -40°C. The housing of the FAW Russian Front Combination Lamp absorbs the kinetic energy of road debris without fracturing. The lens itself is a thick-wall polycarbonate treated with a hard-coat lacquer that resists scratching from sand and pitting from gravel, maintaining optical clarity under abrasive conditions.

Sealing is the most critical aspect of the assembly’s longevity. The interface between the lens and the housing is bonded with a robotic urethane adhesive application, creating a permanent, watertight seal. However, the FAW Russian Front Combination Lamp must also “breathe.” As the air inside the lamp heats up and cools down, pressure differentials occur. To manage this, the assembly incorporates microporous gore-tex vents or breathable membrane patches. These allow air to expand and contract without sucking in moisture or dust, preventing internal condensation fogging that plagues inferior aftermarket lamps.

The electrical interface of the FAW Russian Front Combination Lamp features a rear-mounted, weather-sealed connector. The pin terminals are often gold or silver-plated to prevent fretting corrosion caused by micro-vibrations. The rubber boot sealing the connector is formulated from EPDM synthetic rubber, which retains its flexibility and sealing pressure even in the deep freeze of the Siberian winter. This attention to detail ensures that the FAW Russian Front Combination Lamp never suffers from intermittent connection failures due to water ingress or corrosion.

Mounting Logic: Vibration Isolation

Securement of the FAW Russian Front Combination Lamp is achieved using 8 specialized Combination Bolt fasteners (Part No. CQ1460625). These are not standard screws; they are hex-head bolts with integrated captive washers. The wide surface area of the washer distributes the clamping load across the plastic mounting tabs of the lamp housing. In the FAW Russian Front Combination Lamp application, this distribution is vital to prevent stress cracking of the plastic tabs, which can occur if bolts are over-torqued or if the clamping force is too concentrated.

The mounting points on the FAW Russian Front Combination Lamp are designed with slight flexibility to act as a secondary suspension system for the bulbs. By allowing the lamp housing to move microscopically relative to the rigid steel bumper, high-frequency engine vibrations are dampened before they reach the fragile tungsten filaments. This “soft-mount” strategy significantly extends the mean time between failures (MTBF) for the bulbs within the FAW Russian Front Combination Lamp.

Correct alignment of the Right Front Combination Lamp Assembly (Part No. 3711020A91W-C00) is ensured by locating pins molded into the housing backplate. These pins index into corresponding holes in the bumper bracket, ensuring that the beam pattern is initially aligned relative to the chassis centerline. While fine-tuning adjustment screws are provided for vertical and horizontal aim, this initial physical indexing speeds up the installation process on the assembly line and simplifies collision repair in the field, ensuring the FAW Russian Front Combination Lamp points where it is needed.

Maintenance and Replacement Best Practices

Maintenance of the FAW Russian Front Combination Lamp typically involves bulb replacement. The rear access covers are designed with large tabs that can be operated while wearing thick winter gloves. Sealing gaskets on these covers must be inspected for cracks or compression set every time a bulb is changed. Reusing a damaged gasket on the FAW Russian Front Combination Lamp is the leading cause of moisture ingress and reflector corrosion.

When replacing the entire unit, it is crucial to use the correct Combination Bolt (Part No. CQ1460625). Standard bolts without the wide flange washer can crush the mounting bosses. Additionally, aiming the headlights is a mandatory step after replacement. A misaligned FAW Russian Front Combination Lamp not only reduces the driver’s effective vision distance but can also blind operators of oncoming vehicles, creating a safety hazard on narrow mine roads.

Finally, protecting the lens surface is essential. Cleaning the FAW Russian Front Combination Lamp with a dry cloth when it is covered in abrasive road grime will permanently scour the hard coat, leading to a hazy beam pattern. Operators should be trained to wash the lamps with water or snow before wiping them. Preserving the optical clarity of the FAW Russian Front Combination Lamp is the simplest way to maintain safety margins during the long polar nights.

Conclusion: The Beacon of Operational Continuity

The FAW Russian Front Combination Lamp assembly is more than a cosmetic feature; it is the primary sensory organ for the truck in the dark. Its sophisticated thermal design, impact-resistant materials, and vibration-isolated mounting ensure that the CA3250P66K24L1TE5Z can operate continuously in conditions that would ground lesser vehicles. The 10 components listed form a cohesive system dedicated to one goal: piercing the darkness.

For fleet managers, investing in genuine Left Front Combination Lamp Assembly and Right Front Combination Lamp Assembly units is an investment in uptime. Generic replacements often lack the correct cold-weather plastics and sealing technologies, leading to premature failure and frequent downtime. By maintaining the FAW Russian Front Combination Lamp with authentic parts, operators ensure that their drivers have the visibility required to work safely and efficiently, shift after shift.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.