Lógica de lâmpada combinada frontal russa FAW: Iluminando 10 Elementos de precisão para perfurar a noite ártica

O Lâmpada combinada frontal russa FAW a montagem lógica é o principal sistema de orientação visual para o caminhão basculante CA3250P66K24L1TE5Z. Nos setores mineiros do Norte da Rússia, onde a escuridão do inverno prevalece por 20 horas por dia e as condições de nevasca reduzem a visibilidade a quase zero, o desempenho do Lâmpada combinada frontal russa FAW é uma questão de vida ou morte. Este conjunto integra iluminação de alta intensidade, sinalização, e posicionar marcadores em um único, carcaça robusta projetada para resistir ao impacto de gelo e pedra, mantendo a vedação hermética contra umidade congelante.

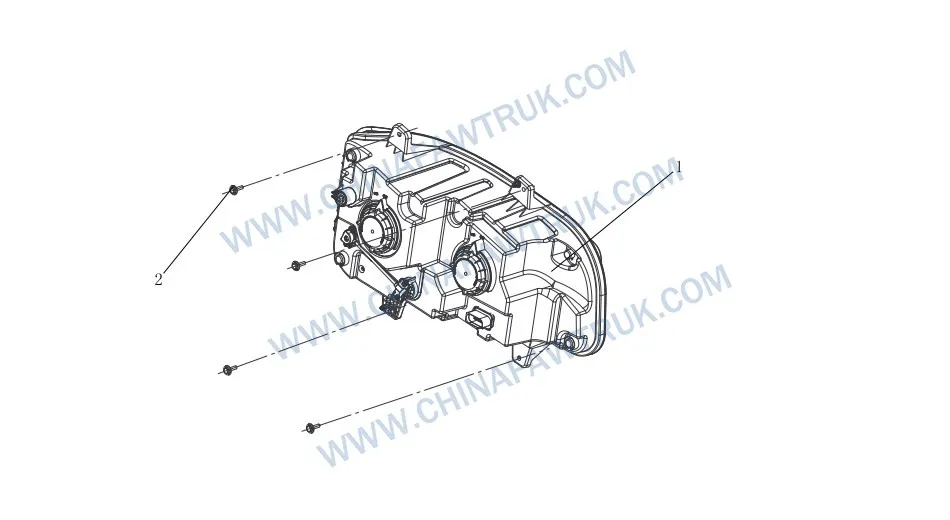

Lâmpada combinada frontal russa FAW

| Não. |

Número da peça |

Nome da peça |

Quantidade |

| 1 | 3711015A91W-C00 | Conjunto de lâmpada combinada dianteira esquerda | 1 |

| 1 | 3711020A91W-C00 | Conjunto de lâmpada combinada dianteira direita | 1 |

| 2 | CQ1460625 | Parafuso de combinação | 8 |

Engenharia Óptica para Condições Polares

A filosofia de design por trás do Lâmpada combinada frontal russa FAW prioriza dois requisitos conflitantes: alto rendimento luminoso e gerenciamento térmico para derretimento de gelo. No design automotivo moderno, LEDs são comuns, mas o Lâmpada combinada frontal russa FAW normalmente utiliza elementos de halogênio de alta potência para os feixes primários. Esta é uma escolha estratégica para o Ártico; o calor infravermelho gerado pela lâmpada halógena aquece a lente de policarbonato, evitando o acúmulo de neve e gelo durante a condução. Sem este efeito de aquecimento passivo, uma lente LED fria ficaria rapidamente obscurecida pela lama congelada, renderizando o Lâmpada combinada frontal russa FAW inútil em uma nevasca.

A geometria óptica do Conjunto de lâmpada combinada dianteira esquerda (Parte não. 3711015A91W-C00) é ajustado especificamente para padrões de tráfego pela direita encontrados na Rússia. O corte do farol baixo é nítido e assimétrico, iluminando o acostamento e a sinalização da estrada sem ofuscar o tráfego em sentido contrário em estradas estreitas, estradas cobertas de neve. As superfícies refletoras dentro do Lâmpada combinada frontal russa FAW são metalizados a vácuo com revestimento de alumínio de alta pureza, protegido por um acabamento de sílica para evitar oxidação e amarelecimento ao longo dos anos de uso. Isto garante que o desempenho fotométrico permanece em conformidade com os regulamentos ECE durante toda a vida útil do veículo.

Além disso, o “91W-C00” designação implica uma construção de filamento resistente. Caminhões basculantes geram vibração significativa, o que pode causar a quebra dos filamentos padrão. As lâmpadas utilizadas no Lâmpada combinada frontal russa FAW apresentam pontes de suporte reforçadas para estabilizar a bobina de tungstênio. Esta resistência à vibração é crítica para manter a iluminação nas superfícies de lavagem das estradas de transporte de mineração. Combinando a capacidade de degelo térmico com componentes internos resistentes a choques, o Lâmpada combinada frontal russa FAW fornece a visibilidade confiável necessária para operações seguras 24 horas por dia.

Materiais e Vedação Ambiental

A habitação do Lâmpada combinada frontal russa FAW é moldado a partir de uma mistura de ABS/policarbonato modificado por impacto. Este material é selecionado por sua ductilidade em baixas temperaturas. Os plásticos padrão tornam-se quebradiços e estilhaçam-se como vidro quando atingidos por uma pedra a -40°C. A habitação do Lâmpada combinada frontal russa FAW absorve a energia cinética dos detritos da estrada sem fraturar. A lente em si é um policarbonato de parede espessa tratado com uma laca de revestimento duro que resiste a arranhões de areia e corrosão de cascalho, mantendo a clareza óptica sob condições abrasivas.

A vedação é o aspecto mais crítico da longevidade da montagem. A interface entre a lente e a caixa é colada com uma aplicação robótica de adesivo de uretano, criando um permanente, vedação estanque. No entanto, o Lâmpada combinada frontal russa FAW também deve “respirar.” À medida que o ar dentro da lâmpada aquece e esfria, ocorrem diferenciais de pressão. Para gerenciar isso, o conjunto incorpora aberturas microporosas de gore-tex ou patches de membrana respiráveis. Isso permite que o ar se expanda e contraia sem sugar umidade ou poeira, evitando o embaçamento da condensação interna que assola lâmpadas de reposição inferiores.

A interface elétrica do Lâmpada combinada frontal russa FAW possui uma montagem traseira, conector à prova de intempéries. Os terminais dos pinos geralmente são banhados a ouro ou prata para evitar corrosão causada por microvibrações. A proteção de borracha que veda o conector é formulada em borracha sintética EPDM, que mantém a sua flexibilidade e pressão de vedação mesmo no frio intenso do inverno siberiano. Essa atenção aos detalhes garante que o Lâmpada combinada frontal russa FAW nunca sofre falhas intermitentes de conexão devido à entrada de água ou corrosão.

Lógica de montagem: Isolamento de vibração

Segurança do Lâmpada combinada frontal russa FAW é conseguido usando 8 especializado Parafuso de combinação fixadores (Parte não. CQ1460625). Estes não são parafusos padrão; eles são parafusos sextavados com arruelas cativas integradas. A ampla área de superfície da arruela distribui a carga de fixação pelas abas de montagem plásticas do alojamento da lâmpada. No Lâmpada combinada frontal russa FAW aplicativo, esta distribuição é vital para evitar rachaduras por tensão nas abas de plástico, o que pode ocorrer se os parafusos estiverem com torque excessivo ou se a força de fixação estiver muito concentrada.

Os pontos de montagem no Lâmpada combinada frontal russa FAW são projetados com ligeira flexibilidade para atuar como um sistema de suspensão secundário para as lâmpadas. Ao permitir que o alojamento da lâmpada se mova microscopicamente em relação ao pára-choques de aço rígido, as vibrações de alta frequência do motor são amortecidas antes de atingirem os frágeis filamentos de tungstênio. Esse “montagem suave” estratégia estende significativamente o tempo médio entre falhas (MTBF) para as lâmpadas dentro do Lâmpada combinada frontal russa FAW.

Alinhamento correto do Conjunto de lâmpada combinada dianteira direita (Parte não. 3711020A91W-C00) é garantido pela localização de pinos moldados na placa traseira da caixa. Esses pinos são indexados nos orifícios correspondentes no suporte do pára-choque, garantindo que o padrão do feixe esteja inicialmente alinhado em relação à linha central do chassi. Embora sejam fornecidos parafusos de ajuste de ajuste fino para mira vertical e horizontal, essa indexação física inicial acelera o processo de instalação na linha de montagem e simplifica o reparo de colisões em campo, garantindo o Lâmpada combinada frontal russa FAW pontos onde é necessário.

Melhores práticas de manutenção e substituição

Manutenção do Lâmpada combinada frontal russa FAW normalmente envolve a substituição da lâmpada. As tampas de acesso traseiro são projetadas com abas grandes que podem ser operadas usando luvas grossas de inverno. As juntas de vedação nessas tampas devem ser inspecionadas quanto a rachaduras ou conjunto de compressão sempre que uma lâmpada for trocada. Reutilizando uma junta danificada no Lâmpada combinada frontal russa FAW é a principal causa de entrada de umidade e corrosão do refletor.

Ao substituir a unidade inteira, é crucial usar o correto Parafuso de combinação (Parte não. CQ1460625). Parafusos padrão sem arruela de flange larga podem esmagar as saliências de montagem. Adicionalmente, apontar os faróis é uma etapa obrigatória após a substituição. Um desalinhado Lâmpada combinada frontal russa FAW não só reduz a distância de visão efetiva do motorista, mas também pode cegar os operadores de veículos que se aproximam, criando um risco à segurança em estradas estreitas de minas.

Finalmente, proteger a superfície da lente é essencial. Limpando o Lâmpada combinada frontal russa FAW com um pano seco quando estiver coberto com sujeira abrasiva da estrada irá limpar permanentemente a camada dura, levando a um padrão de feixe nebuloso. Os operadores devem ser treinados para lavar as lâmpadas com água ou neve antes de limpá-las. Preservando a clareza óptica do Lâmpada combinada frontal russa FAW é a maneira mais simples de manter margens de segurança durante as longas noites polares.

Conclusão: O farol da continuidade operacional

O Lâmpada combinada frontal russa FAW a montagem é mais do que um recurso cosmético; é o principal órgão sensorial do caminhão no escuro. Seu sofisticado design térmico, materiais resistentes ao impacto, e a montagem com isolamento de vibração garantem que o CA3250P66K24L1TE5Z possa operar continuamente em condições que aterrariam veículos menores. O 10 componentes listados formam um sistema coeso dedicado a um objetivo: perfurando a escuridão.

Para gerentes de frota, investindo em genuíno Conjunto de lâmpada combinada dianteira esquerda e Conjunto de lâmpada combinada dianteira direita unidades é um investimento em tempo de atividade. Os substitutos genéricos muitas vezes carecem dos plásticos corretos para climas frios e das tecnologias de vedação, levando a falhas prematuras e tempos de inatividade frequentes. Ao manter o Lâmpada combinada frontal russa FAW com peças autênticas, os operadores garantem que seus motoristas tenham a visibilidade necessária para trabalhar com segurança e eficiência, turno após turno.

Embalagem e Logística

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.