Welcome to this expert technical guide on the FAW Logic Assembly For The Valve Train, the complete “top-end” actuation system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is the most complex assembly of moving parts in the engine.

The FAW Logic Assembly For The Valve Train (or “valvetrain”) contains every component responsible for translating the camshaft’s rotation into the precise opening and closing of all 24 engine valves. This system’s “logic” dictates the engine’s entire breathing and braking performance.

This guide is an essential resource for professional engine rebuilders, machine shops, and technicians. We will deconstruct the entire FAW Logic Assembly For The Valve Train, including every rocker arm, valve, spring, seat, seal, bridge, and solenoid, breaking it down to its smallest serviceable unit.

The core of the actuation system within the FAW Logic Assembly For The Valve Train is the rocker arm set. The parts list details an ‘Intake rocker arm assembly’ (1007110-51B) and an ‘Exhaust rocker arm assembly’ (1007120-51B), with six of each for the six-cylinder engine. These are the levers that the camshaft lobes act upon.

These are not simple levers; they are complex assemblies, likely featuring a roller-follower at the point of contact with the cam to reduce friction and wear. This roller is a high-wear item, and its integrity is key to the health of the FAW Logic Assembly For The Valve Train. The other end of the arm is designed to press on the valve bridge, actuating two valves at once.

The rocker arms are supported by a shaft that is held in place by a series of ‘Rocker arm blocks’. The parts list shows a very specific set: ‘Rocker arm block (one)’ (1007181-81D), ‘Rocker arm block (two)’ (1007182-51B), ‘Rocker arm block (one, two, three)’ (1007165-51B), ‘Rocker arm block (three)’ (1007183-51B), and ‘Rocker arm block (four, five, six)’ (1007175-51B). This highly specific, non-interchangeable set of blocks forms the bearing saddles for the rocker arm shaft, ensuring its perfect alignment over the cylinder head. These blocks, along with the ‘Rocker arm shaft locating sleeve’ (1007163-51B), are fundamental to the rigid structure of the FAW Logic Assembly For The Valve Train.

This engine uses a four-valve-per-cylinder design (two intake, two exhaust), but only has a single camshaft. The “logic” that allows one rocker arm to actuate two valves is the “valve bridge.” The FAW Logic Assembly For The Valve Train includes six ‘Intake valve bridge’ (1007012-81D) and six ‘Exhaust valve bridge assembly’ (1007015-81D) units.

A valve bridge (or yoke) is a small, precise T-shaped component that sits on top of the two valve stems for a single port (e.g., the two intake valves). The rocker arm presses on the center of the bridge, which then transfers this force evenly to both valves, pushing them open in perfect synchrony. The ‘Exhaust valve bridge assembly’ is likely more complex, possibly containing a mechanism related to the engine brake.

The parts list also includes 48 ‘Valve block’ (1007028-53D) units. This quantity (48 = 24 valves x 2) is initially confusing. However, these are likely the hardened steel “tappets” or “caps” that sit on the very tip of the valve stems. The valve bridge’s adjuster screws press on these tappets, not the valve stem itself. This provides a durable, replaceable wear surface, protecting the valve stem. The proper function of these small components is essential for the entire FAW Logic Assembly For The Valve Train to operate correctly.

A key feature of this FAW Logic Assembly For The Valve Train is the ‘Solenoid valve’ (1007164-51B), of which there are two. In a heavy-duty diesel, a solenoid in the valvetrain almost invariably controls the engine brake (e.g., a “Jake Brake”). This solenoid is an electronically controlled valve that manages the flow of high-pressure engine oil.

When the driver activates the engine brake, this solenoid opens, directing oil to a special hydraulic circuit within the FAW Logic Assembly For The Valve Train (likely integrated into the rocker arms or exhaust bridges). This hydraulic pressure overcomes the valve spring and forces the exhaust valves to open at the *top* of the compression stroke, right *before* the fuel injection stroke.

This action releases the highly compressed air (over 500 PSI) from the cylinder, dissipating the energy as noise (the classic “Jake Brake” sound) instead of pushing the piston back down. The engine is effectively turned into a giant, power-absorbing air compressor, which provides significant braking force without using the service brakes. This solenoid is the electronic “brain” of the braking side of the FAW Logic Assembly For The Valve Train. It is protected by a ‘Solenoid valve cover assembly’ (1007160-51B) and sealed with ‘Copper gaskets’ (Q/WC3403-94(8X14)).

This FAW Logic Assembly For The Valve Train list is a complete kit, as it includes the valves themselves: 12 ‘Intake valve’ (1007011-81D) and 12 ‘Exhaust valve’ (1007016-81D). The intake valve has a larger head to maximize airflow *in*, while the exhaust valve has a smaller head and is made of a superior high-temperature alloy (like Inconel or a sodium-filled stem) to survive the 700°C+ exhaust gases.

These valves are sealed against the head by the ‘Intake valve seat’ (1003012-81D) and ‘Exhaust valve seat’ (1003013-81D). These hardened steel rings are pressed into the cylinder head and are the replaceable “wear surface” that the valve seals against. This entire FAW Logic Assembly For The Valve Train is designed to be fully serviceable.

The valves are kept closed by a complex set of springs. The list shows ‘Intake valve spring’ (1007021-81D) and ‘Exhaust valve inner spring’ (1007023-81D). This is a critical detail. The exhaust valve likely uses *two* springs (an inner and an outer, though the outer isn’t listed here) for added pressure. This dual-spring setup is crucial to prevent “valve float” on the exhaust side, where high-RPM exhaust pulses can literally “blow” the valve open, destroying the timing. These springs sit on the ‘Valve spring seat’ (1007024-81D), a hardened washer that protects the aluminum head.

Two components in this FAW Logic Assembly For The Valve Train list are responsible for sealing the valve stems. First, the ‘Valve guide’ (1003014-81D), of which there are 24, is the bronze or iron sleeve pressed into the head. The valve stem slides up and down inside this guide. This component maintains the valve’s alignment and transfers heat from the stem to the water-cooled head.

Second, and most critically for oil consumption, is the ‘Valve guide oil seal assembly’ (1007035-81D), with 24 units. This is a small, “umbrella-shaped” seal, typically made of high-temperature Viton. It clips onto the top of the valve guide. Its purpose is to prevent the “bath” of oil splashing around the rocker arms from being sucked down the valve guide (between the guide and the fast-moving stem) and into the combustion chamber.

Worn valve stem seals are the number one cause of high oil consumption and blue smoke on engine startup. Replacing these 24 seals is a mandatory step in any professional rebuild of the FAW Logic Assembly For The Valve Train to ensure a smoke-free, efficient, and emissions-compliant engine. The entire FAW Logic Assembly For The Valve Train depends on these small seals.

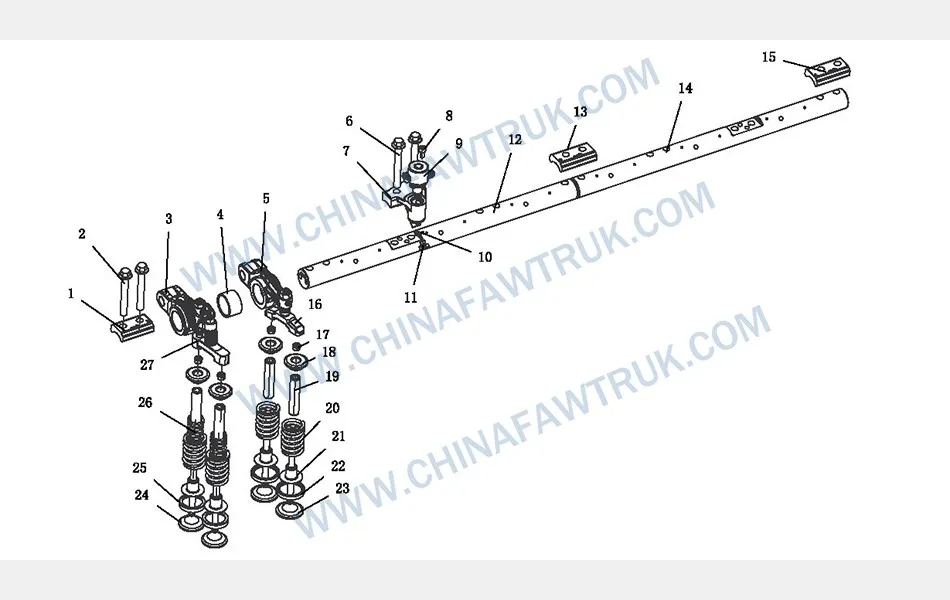

The following table provides the complete, detailed breakdown of all components identified in the ‘Logic Assembly For The Valve Train’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This is the complete parts group for a full top-end valvetrain service of the FAW Logic Assembly For The Valve Train.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1007183-51B | Rocker arm block (three) | 1 |

| 2 | Q1841075T | Hex flange bolt, coarse rod (Standard Type) | 10 |

| 3 | 1007120-51B | Exhaust rocker arm assembly | 6 |

| 4 | 1007163-51B | Rocker arm shaft locating sleeve | 1 |

| 5 | 1007110-51B | Intake rocker arm assembly | 6 |

| 6 | Q1841080T | Hex flange bolt, coarse rod (Standard Type) | 4 |

| 7 | 1007164-51B | Solenoid valve | 2 |

| 8 | CQ2180612 | Inner hex socket head cap screw | 2 |

| 9 | 1007160-51B | Solenoid valve cover assembly | 1 |

| 10 | Q/WC3403-94(8X14) | Copper gasket | 2 |

| 11 | CQ61708 | Hex head bolt | 2 |

| 12 | 1007175-51B | Rocker arm block (four, five, six) | 1 |

| 13 | 1007182-51B | Rocker arm block (two) | 3 |

| 14 | 1007165-51B | Rocker arm block (one, two, three) | 1 |

| 15 | 1007181-81D | Rocker arm block (one) | 1 |

| 16 | 1007012-81D | Intake valve bridge | 6 |

| 17 | 1007028-53D | Valve block | 48 |

| 18 | 1007024-81D | Valve spring seat | 24 |

| 19 | 1003014-81D | Valve guide | 24 |

| 20 | 1007021-81D | Intake valve spring | 24 |

| 21 | 1007035-81D | Valve guide oil seal assembly | 24 |

| 22 | 1003012-81D | Intake valve seat | 12 |

| 23 | 1007011-81D | Intake valve | 12 |

| 24 | 1007016-81D | Exhaust valve | 12 |

| 25 | 1003013-81D | Exhaust valve seat | 12 |

| 26 | 1007023-81D | Exhaust valve inner spring | 12 |

| 27 | 1007015-81D | Exhaust valve bridge assembly | 6 |

The specifications for the FAW Logic Assembly For The Valve Train are defined by its function as the complete 24-valve actuation and engine braking system. The entire FAW Logic Assembly For The Valve Train is a precision-engineered system.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Logic Assembly For The Valve Train |

| Valve Design | 4-Valves per Cylinder (24 Total) |

| Actuation System | Overhead Cam (OHC) with Rocker Arm Assemblies (1007110-51B, 1007120-51B) |

| Multi-Valve Actuation | Valve Bridges (1007012-81D, 1007015-81D) |

| Valve Components | 12x Intake (1007011-81D), 12x Exhaust (1007016-81D) |

| Oil Control | 24x Valve guide oil seal assembly (1007035-81D) | Two

| Special Feature | Solenoid-Actuated Engine Brake (1007164-51B) |

| Rocker Support System | Multi-part Rocker Arm Block system (1007183-51B, etc.) |

| Primary Function | Controls all engine breathing (power) and engine braking (slowing). |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.