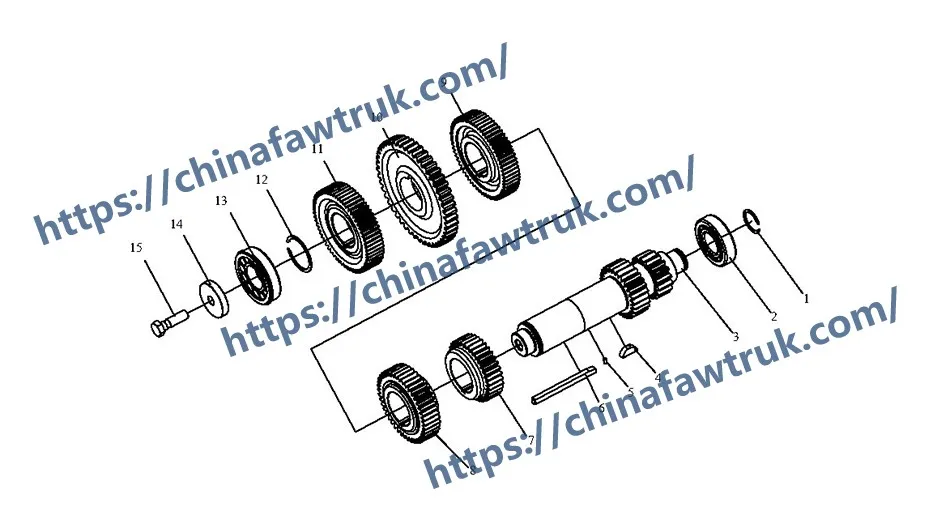

Welcome to this specialized deconstruction of the FAW J6P Left Centre Shaft, a core component within the CA10TA160M gearbox for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This technical guide analyzes the 15 components that create the complete FAW J6P Left Centre Shaft, also known as a countershaft, which is fundamental to the gearbox’s torque-handling capability.

The FAW J6P Left Centre Shaft is one half of a “twin-countershaft” or “dual-countershaft” design. This advanced gearbox logic splits the engine’s torque into two paths (left and right shafts). This dramatically reduces the load on each individual gear tooth, allowing the transmission to handle the massive, low-speed torque required by a fully-loaded dump truck.

This group represents the foundation of the FAW J6P Left Centre Shaft. It includes the shaft itself and the various keys used to permanently lock the drive gears onto it, ensuring the entire assembly spins as one solid unit.

1. Component: ‘Centre shaft’ (1701211-A7G)

This (Comp 3) is the ‘Centre shaft’ itself, the spine of the assembly. It is a single, heavy-duty shaft, precision-machined and forged from hardened steel to be extremely rigid and resistant to torsional (twisting) forces.

The Torque Splitting Logic is its core purpose. As the FAW J6P Left Centre Shaft, it runs parallel to the mainshaft and an identical “Right Centre Shaft.” It receives approximately 50% of the power from the input shaft gear and is in constant, permanent mesh with the “driven” gears on the mainshaft.

2. The “Key” Group (Comp 4, 5, 6)

This group includes: ‘Woodruff key’ (Comp 4), ‘Spring cylindrical pin’ (Comp 5), and ‘Flat key’ (Comp 6). These are all “locating keys” used to fix the gears to the FAW J6P Left Centre Shaft.

The Locking Logic is their function. The drive gears (like Comp 7, 8, 9) are not “free-spinning”; they must be rigidly locked to the FAW J6P Left Centre Shaft. A ‘Woodruff key’ (Comp 4) is a half-moon shaped key that sits in a crescent-shaped slot, locking a gear hub in place. A ‘Flat key’ (Comp 6) is a simple, strong key for a straight slot. A ‘Spring pin’ (Comp 5) is a vibration-proof pin, likely used to secure a gear collar.

This is the primary “working” part of the FAW J6P Left Centre Shaft. These are the fixed gears that provide the “drive” torque to the mainshaft’s “driven” gears.

1. The “Main Gears” (Comp 7, 8, 9)

This group includes: ‘Second gear – centre shaft’ (Comp 7), ‘Third gear – centre shaft’ (Comp 8), and ‘Fourth gear – centre shaft’ (Comp 9). Note: In this design, “First gear” and “Reverse” are often handled by the ‘Reduction gear’ or a separate idler, not this main stack.

The Constant Mesh Logic is key. Unlike the mainshaft gears (which spin freely), all gears on the FAW J6P Left Centre Shaft are *fixed* to the shaft (e.g., by the keys in Core 1). They spin as one single, solid unit.

This means when the engine turns the FAW J6P Left Centre Shaft, all these gears (2nd, 3rd, 4th) are spinning at the same RPM. The driver selects a gear by locking the corresponding “driven” gear (on the mainshaft) to the mainshaft, which completes the power path for that specific ratio.

2. Component: ‘Reduction gear – centre shaft’ (1701217-A7G)

This (Comp 11) is the ‘Reduction gear’. This is likely the main “input” gear of the FAW J6P Left Centre Shaft, which meshes with the ‘First Axis’ (input shaft) gear.

Its Reduction Logic is to provide the first, main gear reduction in the entire gearbox. It multiplies the torque *before* it even gets to the 2nd/3rd/4th gears, providing the massive “grunt” or “pulling power” needed for a dump truck. It is secured on the shaft by its own ‘Snap ring’ (Comp 12).

This component’s logic is to provide a “tap” or “take-off” point for the engine’s power, allowing it to run auxiliary equipment, which is essential for a dump truck.

1. Component: ‘PTO gear – centre shaft’ (1701246-A7G)

This (Comp 10) is the ‘Power Take-Off Gear’. This gear is also fixed to the FAW J6P Left Centre Shaft and spins constantly with it (anytime the clutch is engaged).

The Hydraulic Logic is its application. This gear (Comp 10) is what meshes with the idler gear of the PTO unit (which is bolted to the side of the gearbox housing). When the driver engages the PTO, this gear transmits the engine’s power *out* of the gearbox to run the hydraulic pump for the dump body.

Its position on the FAW J6P Left Centre Shaft is critical. Because this shaft spins whenever the clutch is engaged (even when the main gearbox is in neutral), it allows the dump truck to be stationary but still use the engine’s power to run the hydraulic pump and raise the dump bed.

This final group is responsible for supporting the entire FAW J6P Left Centre Shaft assembly, holding it in its precise location and allowing it to spin smoothly under immense radial and axial loads.

1. The “Bearing” Group (Comp 2, 13)

This includes: ‘Cylindrical roller bearing’ (Comp 2) and ‘Cylindrical roller bearing with stop ring’ (Comp 13). These are the main bearings for the FAW J6P Left Centre Shaft, supporting it at the front and rear of the gearbox case.

The Roller Bearing Logic is used for its superior strength. Unlike ball bearings, roller bearings have a larger contact patch, making them ideal for handling the extremely high *radial* loads (the “pushing” force between gears) inside a heavy-duty gearbox. The ‘stop ring’ on Comp 13 is a snap ring on the *outer* race, which “locates” the bearing in the housing bore.

2. The “Retention” Group (Comp 1, 12, 14, 15)

This group includes: ‘Snap ring – centre shaft rear bearing’ (Comp 1), ‘Snap ring – reduction gear’ (Comp 12), ‘Baffle plate – centre shaft front bearing’ (Comp 14), and ‘Hexagon head bolt with guide neck’ (Comp 15).

The Axial Control Logic is their function. The ‘Snap rings’ (Comp 1, 12) fit into grooves on the FAW J6P Left Centre Shaft itself to lock bearings or gears (like the ‘Reduction gear’, Comp 11) in place, preventing any “axial” (in-and-out) movement.

The Baffle Plate Logic (Comp 14) is critical. This plate, held by the ‘Hexagon head bolt’ (Comp 15), acts as a “retainer” for the front bearing (Comp 13). It also functions as an “oil slinger” or “baffle,” directing lubricating oil into the bearing race while also preventing excessive “splash” from reaching the front seal. This entire group ensures the FAW J6P Left Centre Shaft stays perfectly positioned.

The following table provides the complete, detailed breakdown of all 15 component types in the FAW J6P Left Centre Shaft assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1701236-A7G | Snap ring – centre shaft rear bearing | 1 |

| 2 | NCL308E/YA | Cylindrical roller bearing | 1 |

| 3 | 1701211-A7G | Centre shaft | 1 |

| 4 | 1701226-A7G | Woodruff key | 1 |

| 5 | Q5280510 | Spring cylindrical pin | 1 |

| 6 | 1701228-A7G | Flat key | 1 |

| 7 | 1701212-A7G | Second gear – centre shaft | 1 |

| 8 | 1701213-A7G | Third gear – centre shaft | 1 |

| 9 | 1701214-A7G | Fourth gear – centre shaft | 1 |

| 10 | 1701246-A7G | PTO gear – centre shaft | 1 |

| 11 | 1701217-A7G | Reduction gear – centre shaft | 1 |

| 12 | 1701229-A7G | Snap ring – reduction gear | 1 |

| 13 | NU309NRB/YA6 | Cylindrical roller bearing with stop ring | 1 |

| 14 | 1701233-A7G | Baffle plate – centre shaft front bearing | 1 |

| 15 | CQ1511655 | Hexagon head bolt with guide neck | 1 |

The specifications for the FAW J6P Left Centre Shaft are defined by its role as one of two “countershafts” in a high-torque, twin-countershaft gearbox design.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Left Centre Shaft (Countershaft) |

| Associated Gearbox | CA10TA160M (10-Speed) |

| Primary Logic | Torque Splitting (Twin Countershaft Design) |

| Core Component | ‘Centre shaft’ (1701211-A7G) |

| Gears (Constant Mesh) | 2nd, 3rd, 4th, Reduction, PTO |

| Front Bearing | ‘Cylindrical roller bearing with stop ring’ (NU309NRB/YA6) |

| Rear Bearing | ‘Cylindrical roller bearing’ (NCL308E/YA) |

| Auxiliary Function | ‘PTO gear – centre shaft’ (1701246-A7G) |

| Total Component Types | 15 |

| Associated System | FAW J6P Left Centre Shaft & Right Centre Shaft Assembly |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.