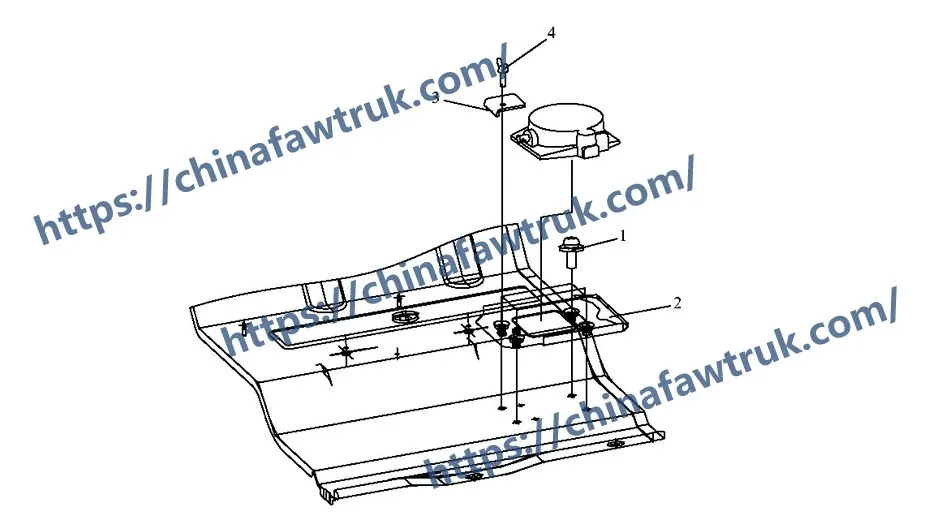

This is a concise technical deconstruction of the FAW J6P Jack Stand (Mounting Bracket) assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This guide analyzes the 4 serviceable component types that form the critical assembly used to store the vehicle’s hydraulic jack.

The FAW J6P Jack Stand assembly is a vital component of the vehicle’s required safety equipment. Its primary function is not to lift the vehicle, but to securely anchor the heavy hydraulic jack in the cab. This anchoring prevents the jack—a heavy, dense piece of metal—from becoming a dangerous projectile inside the cab during a sudden stop, collision, or roll-over. The simplicity of the assembly, featuring a main bracket and clamping components, reflects its dedication to raw security.

This deconstruction analyzes the four key parts: the main mounting bracket, the jack itself (Comp 3), the securing bolt, and the specific wrench used for fastening. Maintaining the integrity of the FAW J6P Jack Stand is non-negotiable for operator safety. The strong hardware is specifically designed to resist the forces exerted by the heavy component during extreme vehicle dynamics. The FAW J6P Jack Stand ensures the essential tool is always secure and ready for use.

This group represents the core structural components of the FAW J6P Jack Stand, dedicated solely to keeping the hydraulic jack secure.

1. Component: ‘Jack fixed bracket assy’ (5101270-A01) – Qty 1

This (Comp 1) is the main mounting bracket. The Secure Storage Logic requires this bracket to be heavy-gauge steel, bolted directly to the cab’s interior floor or wall. It is contoured to hold the base of the hydraulic jack (Comp 3). This is the anchor point for the entire FAW J6P Jack Stand system.

2. Component: ‘Hydraulic jack’ (5101274-A01) – Qty 1

This (Comp 3) is the primary tool secured by the bracket. Its presence emphasizes the essential nature of the FAW J6P Jack Stand. This heavy-duty, bottle-type hydraulic jack is rated for the truck’s operational weight.

3. Component: ‘Cross recessed pan head screw assy’ (Q2360825) – Qty 4

This (Comp 2) is the main bolt used to secure the fixed bracket (Comp 1) to the cab structure. These screws feature a captive washer, ensuring distributed clamping force for the FAW J6P Jack Stand.

This group includes the final pieces of hardware that clamp the jack into the FAW J6P Jack Stand bracket and secure the assembly.

1. Component: ‘Model nut’ (5101276-A01) – Qty 1

This (Comp 4) is the specialized nut used to clamp the jack into the main bracket (Comp 1). The Clamping Nut Logic is that this nut likely works with a threaded rod or bolt that wraps over the top of the hydraulic jack body. It is often a wing-nut or large thumb-nut, allowing the driver to quickly and easily secure or release the jack without requiring tools. This is a key operational feature of the FAW J6P Jack Stand.

2. Component: ‘Jack fixed bracket assy’ (5101270-A01) & ‘Hydraulic jack’ (5101274-A01)

Although listed as the assembly, the functional relationship between the ‘Jack fixed bracket assy’ (Comp 1) and the ‘Hydraulic jack’ (Comp 3) is paramount. The FAW J6P Jack Stand system is designed to provide a quick release for emergency use while meeting safety standards that prevent accidental release. The clamping mechanism (Comp 4) must apply continuous pressure to the hydraulic jack body to resist vibration-induced loosening.

3. Component: Tool Integration

The entire FAW J6P Jack Stand system is intended to house the heaviest tool carried in the cab. The fasteners (Comp 2) must be checked periodically for tightness, as excessive vibration can eventually compromise the anchor points in the cab structure. The simple design minimizes the chance of breakage or failure.

The following table provides the complete, detailed breakdown of all 4 component types in the FAW J6P Jack Stand assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the FAW J6P Jack Stand.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5101270-A01 | Jack fixed bracket assy | 1 |

| 2 | Q2360825 | Cross recessed pan head screw assy | 4 |

| 3 | 5101274-A01 | Hydraulic jack | 1 |

| 4 | 5101276-A01 | Model nut (Jack retention) | 1 |

The specifications for the FAW J6P Jack Stand are defined by its function as a high-security retention device for a 20-ton class hydraulic jack. The assembly is critical for operator safety.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Jack Stand (Storage Bracket) |

| Primary Logic | Secure mounting of tool (jack) to prevent cab projectile danger |

| Jack Tool P/N | 5101274-A01 |

| Bracket P/N | 5101270-A01 |

| Retention Hardware | ‘Model nut’ (5101276-A01) for quick release/lock |

| Mounting Hardware | Q2360825 (Cross recessed pan head screw assy) |

| Total Component Types | 4 |

| Associated System | Cab Interior / Safety Equipment. The FAW J6P Jack Stand is the core safety device. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.