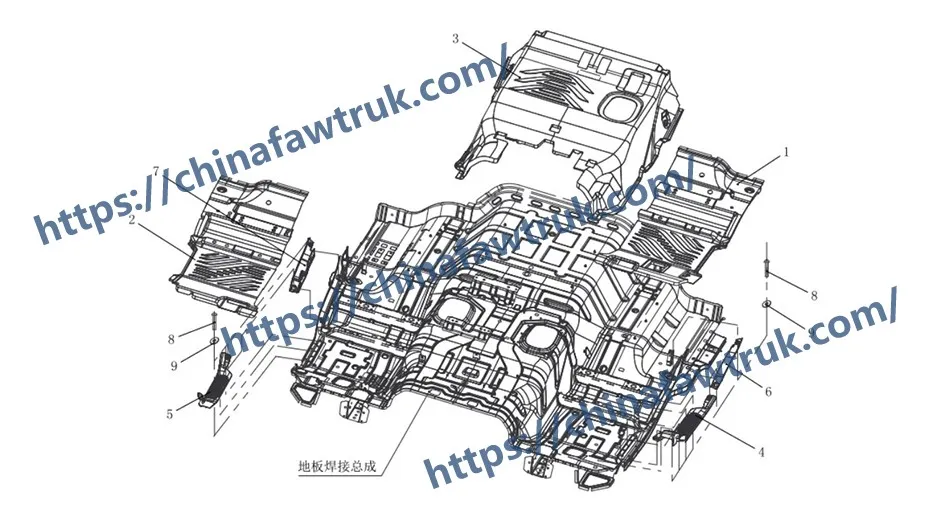

This is a concise technical guide to the FAW J6P Carpet Components assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This deconstruction analyzes the 9 serviceable component types, detailing the multi-piece floor mats, protective trim strips, and the securing hardware that seals the cab floor.

The FAW J6P Carpet Components system is an essential part of the vehicle’s interior. While seemingly simple, its functions are crucial for ergonomics, noise reduction, and structural protection. This system includes specialized mats and retention strips designed to fit the unique contours of the cab floor, which often feature complex shapes due to the transmission tunnel and suspension mounts.

The multi-piece design of the FAW J6P Carpet Components (left, center, right) allows for easier installation and quick removal for cleaning. This deconstruction will analyze the three main mats, the four critical sealing trim strips, and the heavy-duty fastening system used to anchor the entire assembly. A properly fitted set of FAW J6P Carpet Components ensures driver safety by providing a non-slip floor and protecting the expensive underlying electronics and cab metalwork from moisture and abrasion.

This group of FAW J6P Carpet Components provides the primary sound and heat barrier between the noisy chassis and the cab. Their dense material construction is key to driver comfort.

1. Component: ‘Left floor mat’ (5109221-B35) – Qty 1

This (Comp 1) covers the main driver-side floor area. The Noise Reduction Logic is that this thick material significantly dampens road noise and engine vibration transfer.

2. Component: ‘Right floor mat’ (5109222-B35) – Qty 1

This (Comp 2) covers the passenger-side area. Both mats must be fire-retardant and highly durable to resist constant boot traffic and wear.

3. Component: ‘Center floor mat’ (5109226-B35) – Qty 1

This (Comp 3) is designed to drape over the large transmission tunnel. This area is the highest source of heat and noise. The center mat is the most crucial of the FAW J6P Carpet Components for thermal isolation.

This group of components provides the critical security and peripheral sealing for the FAW J6P Carpet Components, anchoring them to the door sills.

1. Component: ‘Left/Right door sill front trim strip’ (5109511/512-B27) – Qty 1 each

This (Comp 4, 5) is a plastic or metal strip that covers and seals the forward edge of the carpet near the door opening. The Sealing Logic ensures the edge of the carpet is pressed firmly against the cab floor, preventing water or dirt ingress.

2. Component: ‘Left/Right door sill middle trim strip’ (5109521/522-B27) – Qty 1 each

This (Comp 6, 7) is the middle section of the trim strip. This ensures the FAW J6P Carpet Components are secured across the full length of the door opening, preventing the mats from lifting up.

The Safety Retention Logic of these trim strips is vital. Loose floor mats can bunch up under the clutch or brake pedal, leading to a dangerous loss of control. By firmly securing the FAW J6P Carpet Components with these strips, this safety hazard is eliminated.

This group includes the hardware required to permanently attach the trim strips and, indirectly, the FAW J6P Carpet Components, to the cab structure.

1. Component: ‘Cross recessed pan head screw’ (Q2140616F6) – Qty 12

This (Comp 8) is the primary screw for securing the various trim strips (Comp 4-7). The Recessed Head Logic ensures the head sits flush or below the surface of the trim strip, preventing snagging or tripping hazards for the driver.

2. Component: ‘Large washer’ (Q40206F6) – Qty 12

This (Comp 9) is used in conjunction with the screws (Comp 8). The Load Distribution Logic dictates that this washer distributes the clamping force over a wider area of the plastic trim strip, preventing the screw head from cracking the trim when tightened down. This is crucial for the longevity of the FAW J6P Carpet Components trim.

3. Component: Maintenance Focus

The entire fastening system for the FAW J6P Carpet Components is designed to be easily removable by a service technician. However, due to constant temperature cycling and vibration, these fasteners should be checked periodically to ensure the mats remain secure and the trim strips are not rattling against the cab structure. This small maintenance step greatly increases the effective service life of the FAW J6P Carpet Components.

The following table provides the complete, detailed breakdown of all 9 component types in the FAW J6P Carpet Components assembly for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This list is essential for ordering spare parts and performing a complete service of the FAW J6P Carpet Components.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 5109221-B35 | Left floor mat | 1 |

| 2 | 5109222-B35 | Right floor mat | 1 |

| 3 | 5109226-B35 | Center floor mat | 1 |

| 4 | 5109511-B27 | Left door sill front trim strip | 1 |

| 5 | 5109512-B27 | Right door sill front trim strip | 1 |

| 6 | 5109521-B27 | Left door sill middle trim strip | 1 |

| 7 | 5109522-B27 | Right door sill middle trim strip | 1 |

| 8 | Q2140616F6 | Cross recessed pan head screw | 12 |

| 9 | Q40206F6 | Large washer | 12 |

The specifications for the FAW J6P Carpet Components are defined by its multi-piece design, ensuring acoustic isolation, ease of cleaning, and precise fitment across the cab floor.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Carpet Components |

| Primary Logic | Acoustic, thermal, and anti-slip isolation for cab floor |

| Mat Structure | 3-Piece design (Left, Right, Center) |

| Sealing Components | Trim strips (e.g., 5109511-B27) covering the door sills |

| Retention Hardware | Q2140616F6 Screws with Large Washers (Q40206F6) |

| Total Component Types | 9 |

| Associated System | Cab Interior / HVAC. The FAW J6P Carpet Components ensure cabin integrity. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.