Welcome to this critical technical guide on the FAW Exhaust Brake system (Part No. 3523010-91W), an essential auxiliary braking component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This system is vital for vehicle safety and maintenance.

The FAW Exhaust Brake is a secondary braking system designed to save the vehicle’s primary service brakes (the air brakes) from overheating and fading, especially during long, steep descents. It functions by converting the engine from a power-producing unit into a power-absorbing air compressor.

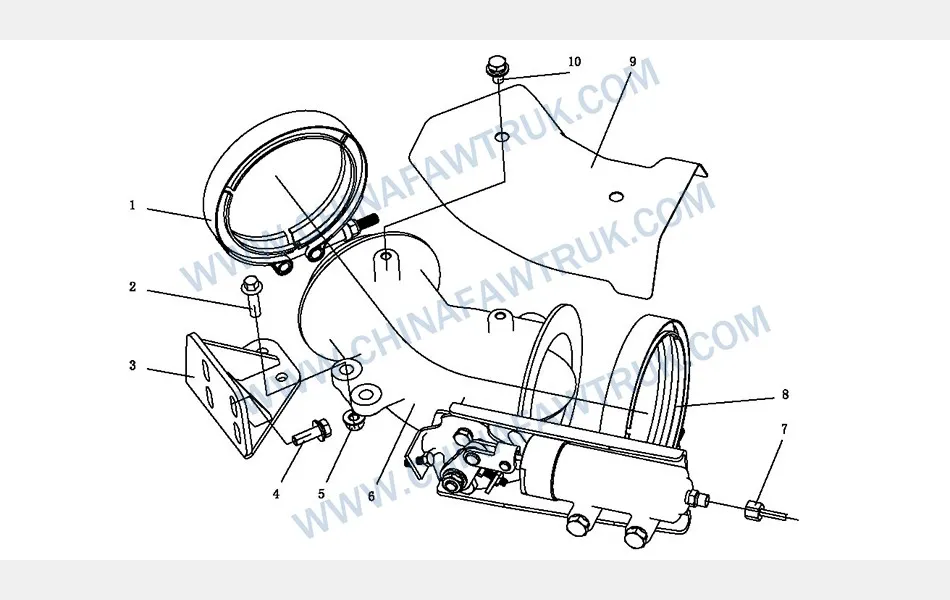

This in-depth guide is an essential resource for professional technicians, fleet managers, and parts specialists. We will deconstruct the entire FAW Exhaust Brake assembly into its 10 serviceable components, including the main valve, the air-actuation system, the heat shield, and all critical mounting hardware.

The heart of the FAW Exhaust Brake system is the ‘Exhaust Brake Valve Assembly’ (3523010-91W). This is a heavy-duty cast-iron housing that contains a “butterfly valve,” which is a flat disc that can pivot 90 degrees to block the exhaust pipe.

This valve is installed in the exhaust system *after* the turbocharger but *before* the main SCR/After-treatment box. When the driver activates the FAW Exhaust Brake, this valve slams shut, creating a massive restriction in the exhaust path. This “plug” creates immense “back pressure” in the exhaust manifold.

This back pressure is the source of the braking power. During the engine’s “exhaust stroke,” the piston must push the burnt gases out of the cylinder. With the FAW Exhaust Brake valve closed, the piston is pushing against this immense back pressure. This requires a huge amount of energy to accomplish, effectively “slowing down” the crankshaft on every single exhaust stroke. This “negative torque” is what provides the braking effect, slowing the entire truck without the driver ever touching the brake pedal.

This FAW Exhaust Brake valve is a high-wear, high-heat component. It must be able to withstand constant, superheated exhaust gases and carbon buildup without seizing. A seized FAW Exhaust Brake is a major fault; if it sticks open, the truck has no engine braking. If it sticks closed, the engine will have no power.

The butterfly valve in the FAW Exhaust Brake is not controlled by an electric motor. It is far too hot and requires too much force. Instead, it is controlled pneumatically (by air pressure). The ‘Air pipe assembly-exhaust solenoid valve to exhaust cylinder’ (3506815-477) is the component that makes this happen.

This is the “logic” of the FAW Exhaust Brake. When the driver flips the switch for the engine brake, the ECU (Engine Control Unit) receives the signal. The ECU then activates an “exhaust solenoid valve” (not listed here, but implied by the pipe’s name). This solenoid is an electronic switch that opens a path for compressed air from the truck’s main air tanks.

This high-pressure air is instantaneously sent through the ‘Air pipe assembly’ (3506815-477) and into a small pneumatic “cylinder” or “actuator” that is mounted directly to the ‘Exhaust Brake Valve Assembly’. This blast of air pushes a piston, which in turn rotates the butterfly valve 90 degrees, slamming it shut. When the driver turns the switch off, the solenoid closes, the air is vented, and a spring on the valve snaps it back open. This makes the FAW Exhaust Brake an incredibly fast-acting and powerful system.

When the FAW Exhaust Brake valve is closed, it blocks all the engine’s exhaust gas. This gas, which is already red-hot from the turbocharger, becomes super-compressed, raising its temperature even further. The entire FAW Exhaust Brake housing and the pipes leading to it can glow cherry red (exceeding 700°C / 1300°F).

This intense radiant heat is a massive fire risk and will melt any nearby components. The ‘Heat shield’ (1203073-92W) is the critical safety component designed to prevent this. It is a stamped, multi-layer metal shield that is mounted near the FAW Exhaust Brake valve.

It functions as a “thermal barrier,” creating a pocket of air and reflecting the radiant heat. This shield protects the chassis frame rail, nearby wiring harnesses, air lines, and the cab floor from melting or catching fire. A missing or damaged heat shield on a FAW Exhaust Brake system is an extreme safety hazard and must be replaced immediately.

The FAW Exhaust Brake system is a heavy, high-vibration component that must be perfectly sealed. This parts list details all the critical mounting hardware.

**Clamps (1203075-50A / 1203075-55A):** The ‘Clamp Assembly’ units are not simple hose clamps. These are heavy-duty, high-temperature “V-band” or “Marmon” clamps. They are designed to create a high-pressure, leak-proof seal between the flanged ends of the turbocharger, the FAW Exhaust Brake valve, and the connecting pipes. A leak here will cause a loud “scream” or “whistle” and a total loss of braking power.

**Bracket (1203065-92W):** The ‘Bracket assembly-connecting pipe’ is the main structural support. It bolts to the chassis or engine and holds the weight of the exhaust piping, preventing the heavy FAW Exhaust Brake valve from cracking the turbo flange.

**Fasteners:** The entire system is held together with high-tensile, heat-resistant hardware. ‘Hex flange bolts’ (Q1840830) and ‘Combination Bolts’ (CQ1460825, CQ1460816) are used for the brackets. The ‘Hex head flange lock nut’ (CQ32608) is a special prevailing-torque nut designed to resist loosening, even under the intense heat and vibration of the FAW Exhaust Brake.

The following table provides the complete, detailed breakdown of all 10 components identified in the ‘Exhaust Brake’ diagram for the FAW CA4251P66K24T1A3E5 tractor. The FAW Exhaust Brake is a critical safety and maintenance-saving device.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1203075-50A | Clamp Assembly | 1 |

| 2 | Q1840830 | Hex flange bolt, coarse rod (Standard Type) | 2 |

| 3 | 1203065-92W | Bracket assembly-connecting pipe | 1 |

| 4 | CQ1460825 | Combination Bolt | 4 |

| 5 | CQ32608 | Hex head flange lock nut | 2 |

| 6 | 3523010-91W | Exhaust Brake Valve Assembly (as-per-sample) | 1 |

| 7 | 3506815-477 | Air pipe assembly-exhaust solenoid valve to exhaust cylinder | 1 |

| 8 | 1203075-55A | Clamp Assembly (as-per-sample) | 1 |

| 9 | 1203073-92W | Heat shield | 1 |

| 10 | CQ1460816 | Combination Bolt | 2 |

The specifications for the FAW Exhaust Brake are defined by its function as a high-temperature, pneumatically-actuated auxiliary braking system. The entire FAW Exhaust Brake assembly is a safety-critical component.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Exhaust Brake |

| Main Valve Assembly | 1x (Part No. 3523010-91W) |

| Brake Type | Exhaust Gas Throttling (Butterfly Valve) |

| Actuation System | Pneumatic (Air-Actuated) via Solenoid |

| Actuation Line | 1x Air Pipe Assembly (3506815-477) |

| Thermal Protection | 1x Heat Shield (1203073-92W) |

| Mounting System | 1x Bracket Assembly (1203065-92W) | Type

| Main Clamps | V-Band / Marmon Style (1203075-50A, 1203075-55A) |

| Primary Function | To slow the vehicle by creating engine back-pressure, saving the service brakes. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.