Добро пожаловать в это важное техническое руководство по FAW Exhaust Brake система (Часть №. 3523010-91Вт), an essential auxiliary braking component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 дизельный полуприцеп тягач. This system is vital for vehicle safety and maintenance.

The FAW Exhaust Brake is a secondary braking system designed to save the vehicle’s primary service brakes (the air brakes) from overheating and fading, especially during long, крутые спуски. It functions by converting the engine from a power-producing unit into a power-absorbing air compressor.

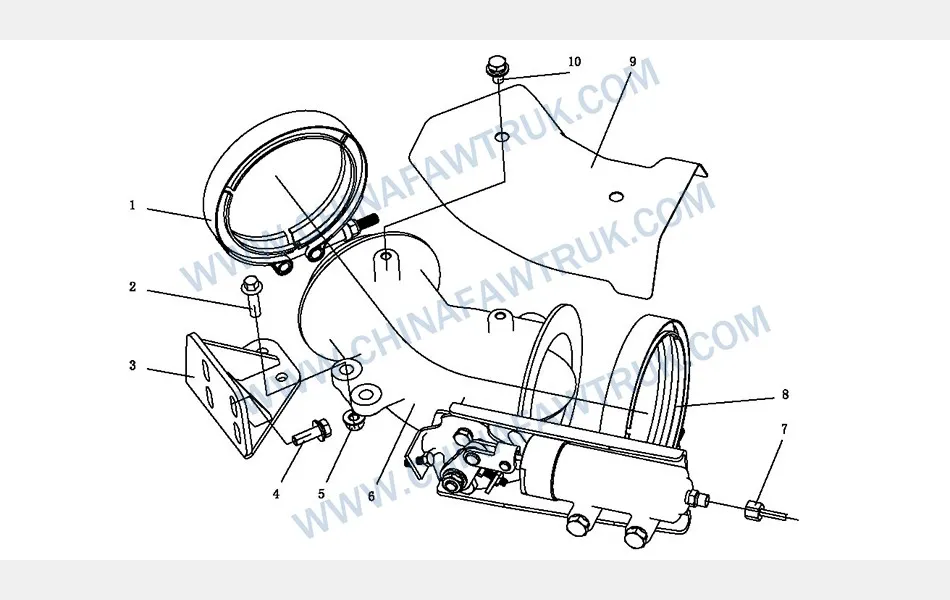

Это подробное руководство является важным ресурсом для профессиональных технических специалистов., менеджеры автопарка, и специалисты по запчастям. Мы разберем всю FAW Exhaust Brake сборка в свой 10 исправные компоненты, including the main valve, the air-actuation system, the heat shield, и все критически важное монтажное оборудование.

Сердце FAW Exhaust Brake system is the ‘Exhaust Brake Valve Assembly’ (3523010-91Вт). This is a heavy-duty cast-iron housing that contains a “butterfly valve,” which is a flat disc that can pivot 90 degrees to block the exhaust pipe.

This valve is installed in the exhaust system *after* the turbocharger but *before* the main SCR/After-treatment box. When the driver activates the FAW Exhaust Brake, this valve slams shut, creating a massive restriction in the exhaust path. Этот “затыкать” creates immense “back pressure” in the exhaust manifold.

This back pressure is the source of the braking power. During the engine’s “exhaust stroke,” the piston must push the burnt gases out of the cylinder. With the FAW Exhaust Brake valve closed, the piston is pushing against this immense back pressure. This requires a huge amount of energy to accomplish, эффективно “slowing down” the crankshaft on every single exhaust stroke. Этот “negative torque” is what provides the braking effect, slowing the entire truck without the driver ever touching the brake pedal.

Этот FAW Exhaust Brake valve is a high-wear, high-heat component. It must be able to withstand constant, superheated exhaust gases and carbon buildup without seizing. A seized FAW Exhaust Brake is a major fault; если он залипнет, the truck has no engine braking. Если он застрял в закрытом положении, the engine will have no power.

The butterfly valve in the FAW Exhaust Brake is not controlled by an electric motor. It is far too hot and requires too much force. Вместо, it is controlled pneumatically (by air pressure). The ‘Air pipe assembly-exhaust solenoid valve to exhaust cylinder’ (3506815-477) is the component that makes this happen.

Это “логика” принадлежащий FAW Exhaust Brake. When the driver flips the switch for the engine brake, the ECU (Блок управления двигателем) receives the signal. The ECU then activates an “exhaust solenoid valve” (здесь не указано, but implied by the pipe’s name). This solenoid is an electronic switch that opens a path for compressed air from the truck’s main air tanks.

This high-pressure air is instantaneously sent through the ‘Air pipe assembly’ (3506815-477) and into a small pneumatic “цилиндр” или “привод” that is mounted directly to the ‘Exhaust Brake Valve Assembly’. This blast of air pushes a piston, which in turn rotates the butterfly valve 90 степени, slamming it shut. When the driver turns the switch off, the solenoid closes, the air is vented, and a spring on the valve snaps it back open. Это делает FAW Exhaust Brake an incredibly fast-acting and powerful system.

Когда FAW Exhaust Brake valve is closed, it blocks all the engine’s exhaust gas. This gas, which is already red-hot from the turbocharger, becomes super-compressed, raising its temperature even further. Весь FAW Exhaust Brake housing and the pipes leading to it can glow cherry red (exceeding 700°C / 1300° F.).

This intense radiant heat is a massive fire risk and will melt any nearby components. The ‘Heat shield’ (1203073-92Вт) is the critical safety component designed to prevent this. It is a stamped, multi-layer metal shield that is mounted near the FAW Exhaust Brake клапан.

It functions as a “thermal barrier,” creating a pocket of air and reflecting the radiant heat. This shield protects the chassis frame rail, nearby wiring harnesses, air lines, and the cab floor from melting or catching fire. A missing or damaged heat shield on a FAW Exhaust Brake system is an extreme safety hazard and must be replaced immediately.

The FAW Exhaust Brake system is a heavy, high-vibration component that must be perfectly sealed. This parts list details all the critical mounting hardware.

**Зажимы (1203075-50А / 1203075-55А):** The ‘Clamp Assembly’ units are not simple hose clamps. Это сверхмощные, высокотемпературный “V-band” или “Marmon” зажимы. They are designed to create a high-pressure, leak-proof seal between the flanged ends of the turbocharger, а FAW Exhaust Brake клапан, and the connecting pipes. A leak here will cause a loud “scream” или “свист” and a total loss of braking power.

**Скобка (1203065-92Вт):** The ‘Bracket assembly-connecting pipe’ is the main structural support. It bolts to the chassis or engine and holds the weight of the exhaust piping, preventing the heavy FAW Exhaust Brake valve from cracking the turbo flange.

**Крепежи:** The entire system is held together with high-tensile, heat-resistant hardware. «Болты с шестигранной головкой’ (Q1840830) и «Комбинированные болты’ (CQ1460825, CQ1460816) are used for the brackets. The ‘Hex head flange lock nut’ (CQ32608) is a special prevailing-torque nut designed to resist loosening, even under the intense heat and vibration of the FAW Exhaust Brake.

В следующей таблице представлена полная, подробная разбивка всех 10 components identified in the ‘Exhaust Brake’ схема трактора FAW CA4251P66K24T1A3E5. The FAW Exhaust Brake is a critical safety and maintenance-saving device.

| Отметка | Часть №. | Наименование | Количество |

|---|---|---|---|

| 1 | 1203075-50А | Clamp Assembly | 1 |

| 2 | Q1840830 | Болт с шестигранной головкой, грубый стержень (Стандартный тип) | 2 |

| 3 | 1203065-92Вт | Bracket assembly-connecting pipe | 1 |

| 4 | CQ1460825 | Комбинированный болт | 4 |

| 5 | CQ32608 | Контргайка фланца с шестигранной головкой | 2 |

| 6 | 3523010-91Вт | Exhaust Brake Valve Assembly (по образцу) | 1 |

| 7 | 3506815-477 | Air pipe assembly-exhaust solenoid valve to exhaust cylinder | 1 |

| 8 | 1203075-55А | Clamp Assembly (по образцу) | 1 |

| 9 | 1203073-92Вт | Тепловой экран | 1 |

| 10 | CQ1460816 | Комбинированный болт | 2 |

Технические характеристики FAW Exhaust Brake are defined by its function as a high-temperature, pneumatically-actuated auxiliary braking system. Весь FAW Exhaust Brake assembly is a safety-critical component.

| Приложение для автомобиля | FAW Цзефан CA4251P66K24T1A3E5 6×4 Трактор |

| Группа компонентов | FAW Exhaust Brake |

| Main Valve Assembly | 1х (Часть №. 3523010-91Вт) |

| Тип тормоза | Exhaust Gas Throttling (Butterfly Valve) |

| Actuation System | Пневматический (Пневматический) via Solenoid |

| Actuation Line | 1x Air Pipe Assembly (3506815-477) |

| Thermal Protection | 1x Heat Shield (1203073-92Вт) |

| Система крепления | 1x Bracket Assembly (1203065-92Вт) | Тип

| Main Clamps | V-Band / Marmon Style (1203075-50А, 1203075-55А) |

| Основная функция | To slow the vehicle by creating engine back-pressure, saving the service brakes. |

Запчасти ФАВ, включая блок цилиндров в сборе, тщательно упакованы, чтобы обеспечить безопасную доставку. Каждый компонент закреплен защитными материалами для предотвращения повреждений при транспортировке.. Логистическая сеть гарантирует своевременную доставку по всему миру., поддержка эффективных операций по техническому обслуживанию. Ниже приведено изображение, иллюстрирующее стандартную упаковку запчастей для грузовиков FAW., демонстрация внимания к деталям в обращении и хранении.

Такой подход к упаковке сводит к минимуму риск коррозии или ударного повреждения., обеспечение доставки таких деталей, как блок цилиндров FAW в сборе, в идеальном состоянии.. Клиенты могут положиться на логистику FAW для обеспечения стабильного качества и надежности..