Bienvenido a esta completa guía técnica sobre el Conjunto del primer eje FAW y engranaje de entrada, el completo “aporte” group for the manual transmission in the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. This assembly is the critical link between the engine’s clutch and the transmission’s gearset.

El Conjunto del primer eje FAW y engranaje de entrada (also known as the input shaft) is responsible for receiving 100% of the engine’s torque from the clutch disc. It holds the main ‘Input Gear’ (1701121-A0L) cual, Sucesivamente, drives the transmission’s counter-shaft, setting the entire gear-driven system in motion.

Esta guía detallada es un recurso esencial para técnicos profesionales de transmisiones y especialistas en repuestos.. Deconstruiremos todo Conjunto del primer eje FAW y engranaje de entrada, breaking it down into its 11 componentes reparables, incluyendo el eje principal, the input gear, the critical support bearings, and all the circlips and seals that ensure its precise alignment and leak-free operation.

El Conjunto del primer eje FAW y engranaje de entrada is composed of two primary, named components:

**1. Primer eje – Transmisión (1701112-A7G):** Este es el “Primer eje,” more commonly known as the transmission input shaft. Es de alta resistencia, hardened steel shaft. The front “nariz” of this shaft is splined and extends into the clutch housing, where it engages with the splined hub of the clutch disc. This spline is what allows the Conjunto del primer eje FAW y engranaje de entrada to be connected (and disconnected) from the engine’s flywheel.

**2. Engranaje de entrada – Primer eje (1701121-A0L):** Este es el “Input Gear.” este grande, helically-cut gear is permanently fixed (either splined or press-fit) onto the ‘First Shaft’. Its function is to transfer 100% of the engine’s torque from the shaft to the transmission’s counter-shaft, which is in constant mesh with this gear. The helical cut of the teeth is a critical design feature, ensuring quiet operation and maximum surface area contact for high-torque transfer. A chipped or worn tooth on this gear is a catastrophic failure for the Conjunto del primer eje FAW y engranaje de entrada and the entire transmission.

todo el Conjunto del primer eje FAW y engranaje de entrada must be supported as it spins under immense loads. This is the job of the ‘Deep groove ball bearing with stop ring’ (6212-ZNBR/C3YB2). This is the main bearing for the input shaft.

este grande, heavy-duty ball bearing (a “6212” serie) is pressed onto the ‘First Shaft’ (1701112-A7G). Its outer race is then secured in a precision-bored hole in the ‘Front housing’ (bell housing) of the transmission case. This bearing must handle both the “radial” carga (the sideways force from the gears pushing against each other) y el “axial” carga (the push/pull force from the clutch being engaged and disengaged).

El “anillo de parada” (or snap ring) on the bearing’s outer race is a critical feature. This ring fits into a groove in the transmission housing, locking the bearing (and thus the entire Conjunto del primer eje FAW y engranaje de entrada) in its precise fore-and-aft position. This is a vital function for maintaining the perfect gear mesh inside the transmission.

El Conjunto del primer eje FAW y engranaje de entrada requires incredibly precise “juego final” (the amount of in-and-out movement). This is controlled by a complex set of “ajuste selectivo” circlips and a gasket.

The parts list calls out four separate ‘Circlip – cojinete trasero del primer eje’ elementos (1701131-A7G, 1701132-A7G, 1701133-A7G, and 1701134-A7G), as well as a ‘Gasket – cojinete trasero del primer eje’ (1701123-A7G). This indicates that these parts are not identical.

Este es un “ajuste selectivo” o “shimming” sistema. The different part numbers for the circlips correspond to different, precise thicknesses. Durante el montaje, a technician must measure the shaft’s end-play with a dial indicator. They will then consult a chart and select the correct-thickness circlip and/or gasket from this set. This process “sets the preload” on the main bearing. Using the wrong circlip will cause the Conjunto del primer eje FAW y engranaje de entrada to be too “ajustado” (leading to bearing failure) or too “perder” (leading to gear whine and misalignment).

A separate ‘Circlip – marcha atrás’ (1701314-A7G) is also listed. This is a standard snap ring used to hold the reverse idler gear in its proper place on its own shaft, which is also part of the Conjunto del primer eje FAW y engranaje de entrada‘s overall function.

El Conjunto del primer eje FAW y engranaje de entrada is completed by two critical, but small, componentes: the ‘Bushing’ (1701111-A7G) and the ‘Oil seal – primer eje’ (1701135-A7G).

**1. El 'sello de aceite’ (1701135-A7G):** Este es el principal “input shaft seal.” It is a radial lip seal that is pressed into the front of the transmission housing. Its flexible rubber lip rides on a polished surface of the first shaft. Its only job is to keep the transmission’s gear oil *inside* the transmission. A failure of this seal is a critical failure of the Conjunto del primer eje FAW y engranaje de entrada sistema, as it allows gear oil to leak into the dry clutch housing, saturating the clutch disc and causing it to slip and fail.

**2. El 'buje’ (1701111-A7G):** Este es el “pilot bushing” for the main shaft. The rear of the ‘First Shaft’ (eje de entrada) is hollowed out. El “nariz” o “consejo” of the transmission’s *main* shaft (the one with all the sliding gears) fits *inside* this hollowed-out section. This bushing, made of bronze or a similar low-friction material, is pressed into this hole. It provides the front support for the entire main shaft. A worn bushing here will cause the main shaft to “tambalearse,” leading to gear grinding, vibración, and shifting problems. It is a critical, often-overlooked part of the Conjunto del primer eje FAW y engranaje de entrada.

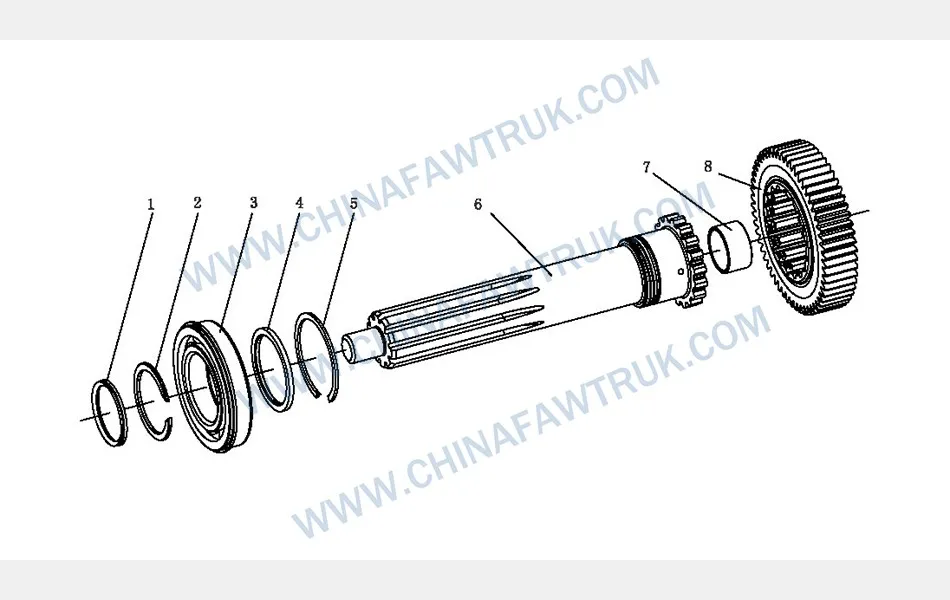

La siguiente tabla proporciona la información completa, desglose detallado de todos 11 components identified in the ‘First Shaft Assembly and Input Gear’ diagrama para el tractor FAW CA4251P66K24T1A3E5. Una reconstrucción del Conjunto del primer eje FAW y engranaje de entrada requires careful selection of the correct circlips.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1701135-A7G | Sello de petróleo – primer eje | 1 |

| 2 | 1701131-A7G | clip de seguridad – cojinete trasero del primer eje | 1 |

| 3 | 1701132-A7G | clip de seguridad – cojinete trasero del primer eje (See 1701131-A7G) | 1 |

| 4 | 1701133-A7G | clip de seguridad – cojinete trasero del primer eje (See 1701131-A7G) | 1 |

| 5 | 1701134-A7G | clip de seguridad – cojinete trasero del primer eje (See 1701131-A7G) | 1 |

| 6 | 6212-ZNBR/C3YB2 | Deep groove ball bearing with stop ring | 1 |

| 7 | 1701123-A7G | Empaquetadora – cojinete trasero del primer eje | 1 |

| 8 | 1701314-A7G | clip de seguridad – marcha atrás | 1 |

| 9 | 1701112-A7G | Primer eje – transmisión | 1 |

| 10 | 1701111-A7G | Cojinete | 1 |

| 11 | 1701121-A0L | Engranaje de entrada – primer eje | 1 |

Las especificaciones para el Conjunto del primer eje FAW y engranaje de entrada are defined by its function as the primary torque input for the transmission. Este Conjunto del primer eje FAW y engranaje de entrada is a precision-balanced, high-strength assembly.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Conjunto del primer eje FAW y engranaje de entrada |

| N/P del eje principal | 1701112-A7G (Eje de entrada) |

| N/P del engranaje principal | 1701121-A0L (Engranaje de entrada) |

| Main Bearing P/N | 6212-ZNBR/C3YB2 (Rodamiento de bolas de ranura profunda) |

| N/P del sello principal | 1701135-A7G (Sello de aceite) |

| Pilot Bushing P/N | 1701111-A7G |

| End-Play Control | Selective-fit Circlips (1701131/2/3/4-A7G) |

| Función primaria | To transmit 100% of engine torque from the clutch disc to the transmission’s counter-shaft. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.