Bem-vindo a este guia técnico abrangente sobre o Primeiro conjunto de eixo e engrenagem de entrada FAW, o completo “entrada” group for the manual transmission in the FAW Jiefang CA4251P66K24T1A3E5 6×4 trator semirreboque diesel. This assembly is the critical link between the engine’s clutch and the transmission’s gearset.

O Primeiro conjunto de eixo e engrenagem de entrada FAW (also known as the input shaft) is responsible for receiving 100% of the engine’s torque from the clutch disc. It holds the main ‘Input Gear’ (1701121-A0L) qual, por sua vez, drives the transmission’s counter-shaft, setting the entire gear-driven system in motion.

Este guia detalhado é um recurso essencial para técnicos profissionais de transmissão e especialistas em peças.. Vamos desconstruir todo Primeiro conjunto de eixo e engrenagem de entrada FAW, breaking it down into its 11 componentes reparáveis, incluindo o eixo principal, the input gear, the critical support bearings, and all the circlips and seals that ensure its precise alignment and leak-free operation.

O Primeiro conjunto de eixo e engrenagem de entrada FAW is composed of two primary, named components:

**1. First Shaft – Transmissão (1701112-A7G):** Este é o “First Shaft,” more commonly known as the transmission input shaft. It is a high-strength, hardened steel shaft. A frente “nariz” of this shaft is splined and extends into the clutch housing, where it engages with the splined hub of the clutch disc. This spline is what allows the Primeiro conjunto de eixo e engrenagem de entrada FAW to be connected (and disconnected) from the engine’s flywheel.

**2. Input Gear – First Shaft (1701121-A0L):** Este é o “Input Gear.” Este grande, helically-cut gear is permanently fixed (either splined or press-fit) onto the ‘First Shaft’. Its function is to transfer 100% of the engine’s torque from the shaft to the transmission’s counter-shaft, which is in constant mesh with this gear. The helical cut of the teeth is a critical design feature, ensuring quiet operation and maximum surface area contact for high-torque transfer. A chipped or worn tooth on this gear is a catastrophic failure for the Primeiro conjunto de eixo e engrenagem de entrada FAW and the entire transmission.

O inteiro Primeiro conjunto de eixo e engrenagem de entrada FAW must be supported as it spins under immense loads. This is the job of the ‘Deep groove ball bearing with stop ring’ (6212-ZNBR/C3YB2). Este é o rolamento principal do eixo de entrada.

Este grande, heavy-duty ball bearing (a “6212” série) is pressed onto the ‘First Shaft’ (1701112-A7G). Its outer race is then secured in a precision-bored hole in the ‘Front housing’ (caixa de sino) of the transmission case. This bearing must handle both the “radial” carregar (the sideways force from the gears pushing against each other) e o “axial” carregar (the push/pull force from the clutch being engaged and disengaged).

O “anel de parada” (or snap ring) na pista externa do rolamento é uma característica crítica. Este anel se encaixa em uma ranhura na carcaça da transmissão, travando o rolamento (e assim todo Primeiro conjunto de eixo e engrenagem de entrada FAW) em sua posição precisa para frente e para trás. Esta é uma função vital para manter a engrenagem perfeita dentro da transmissão.

O Primeiro conjunto de eixo e engrenagem de entrada FAW requer incrivelmente preciso “jogo final” (a quantidade de movimento de entrada e saída). This is controlled by a complex set of “ajuste seletivo” circlips and a gasket.

The parts list calls out four separate ‘Circlip – Rolamento traseiro do primeiro eixo’ items (1701131-A7G, 1701132-A7G, 1701133-A7G, and 1701134-A7G), as well as a ‘Gasket – Rolamento traseiro do primeiro eixo’ (1701123-A7G). This indicates that these parts are not identical.

Este é um “ajuste seletivo” ou “shimming” sistema. The different part numbers for the circlips correspond to different, precise thicknesses. Durante a montagem, a technician must measure the shaft’s end-play with a dial indicator. They will then consult a chart and select the correct-thickness circlip and/or gasket from this set. This process “sets the preload” on the main bearing. Using the wrong circlip will cause the Primeiro conjunto de eixo e engrenagem de entrada FAW to be too “apertado” (leading to bearing failure) or too “solto” (leading to gear whine and misalignment).

A separate ‘Circlip – engrenagem reversa’ (1701314-A7G) is also listed. This is a standard snap ring used to hold the reverse idler gear in its proper place on its own shaft, which is also part of the Primeiro conjunto de eixo e engrenagem de entrada FAW‘s overall function.

O Primeiro conjunto de eixo e engrenagem de entrada FAW is completed by two critical, but small, componentes: the ‘Bushing’ (1701111-A7G) and the ‘Oil seal – primeiro eixo’ (1701135-A7G).

**1. O ‘selo de óleo’ (1701135-A7G):** Este é o principal “vedação do eixo de entrada.” It is a radial lip seal that is pressed into the front of the transmission housing. Its flexible rubber lip rides on a polished surface of the first shaft. Its only job is to keep the transmission’s gear oil *inside* the transmission. Uma falha deste selo é uma falha crítica do Primeiro conjunto de eixo e engrenagem de entrada FAW sistema, as it allows gear oil to leak into the dry clutch housing, saturating the clutch disc and causing it to slip and fail.

**2. A ‘Bucha’ (1701111-A7G):** Este é o “bucha piloto” for the main shaft. The rear of the ‘First Shaft’ (eixo de entrada) está oco. O “nariz” ou “dica” of the transmission’s *main* shaft (aquele com todas as engrenagens deslizantes) cabe *dentro* desta seção oca. This bushing, made of bronze or a similar low-friction material, is pressed into this hole. Fornece suporte frontal para todo o eixo principal. Uma bucha desgastada aqui fará com que o eixo principal “oscilar,” leading to gear grinding, vibração, and shifting problems. It is a critical, often-overlooked part of the Primeiro conjunto de eixo e engrenagem de entrada FAW.

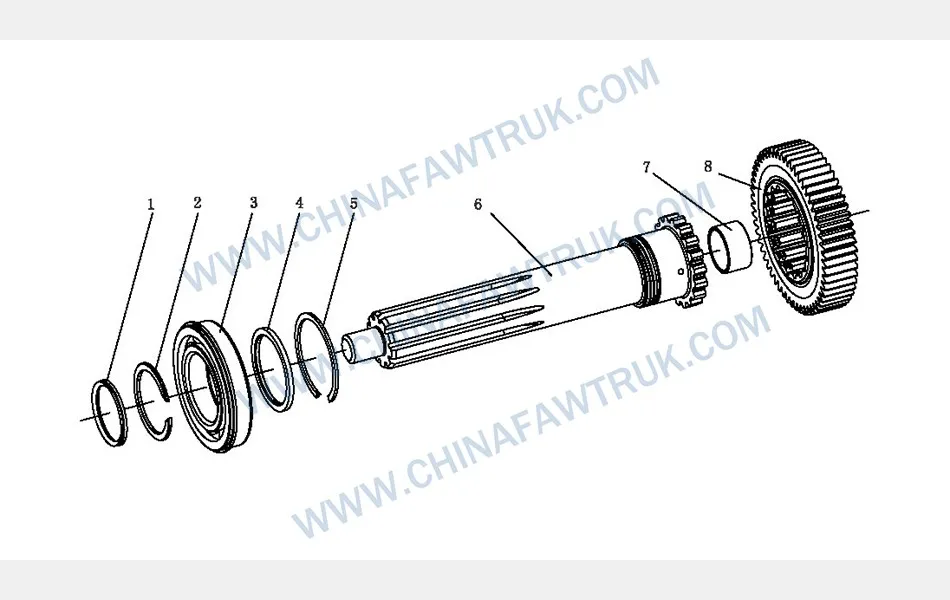

A tabela a seguir fornece o completo, detalhamento de todos 11 components identified in the ‘First Shaft Assembly and Input Gear’ diagrama para o trator FAW CA4251P66K24T1A3E5. Uma reconstrução do Primeiro conjunto de eixo e engrenagem de entrada FAW requer seleção cuidadosa dos anéis de retenção corretos.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 1701135-A7G | Vedação de óleo – primeiro eixo | 1 |

| 2 | 1701131-A7G | Circlip – Rolamento traseiro do primeiro eixo | 1 |

| 3 | 1701132-A7G | Circlip – Rolamento traseiro do primeiro eixo (Consulte 1701131-A7G) | 1 |

| 4 | 1701133-A7G | Circlip – Rolamento traseiro do primeiro eixo (Consulte 1701131-A7G) | 1 |

| 5 | 1701134-A7G | Circlip – Rolamento traseiro do primeiro eixo (Consulte 1701131-A7G) | 1 |

| 6 | 6212-ZNBR/C3YB2 | Rolamento rígido de esferas com anel limitador | 1 |

| 7 | 1701123-A7G | Junta – Rolamento traseiro do primeiro eixo | 1 |

| 8 | 1701314-A7G | Circlip – engrenagem reversa | 1 |

| 9 | 1701112-A7G | Primeiro eixo – transmissão | 1 |

| 10 | 1701111-A7G | Casquilho | 1 |

| 11 | 1701121-A0L | Engrenagem de entrada – primeiro eixo | 1 |

As especificações para o Primeiro conjunto de eixo e engrenagem de entrada FAW são definidos por sua função como a entrada primária de torque para a transmissão. Esse Primeiro conjunto de eixo e engrenagem de entrada FAW é um equilíbrio de precisão, montagem de alta resistência.

| Aplicação em veículos | FAW Jiefang CA4251P66K24T1A3E5 6×4 Trator |

| Grupo de Componentes | Primeiro conjunto de eixo e engrenagem de entrada FAW |

| Eixo principal P/N | 1701112-A7G (Eixo de entrada) |

| Engrenagem principal P/N | 1701121-A0L (Input Gear) |

| Rolamento principal P/N | 6212-ZNBR/C3YB2 (Rolamento de esfera de ranhura profunda) |

| Selo principal P/N | 1701135-A7G (Oil Seal) |

| Bucha Piloto P/N | 1701111-A7G |

| Controle de fim de jogo | Clipes de ajuste seletivo (1701131/2/3/4-A7G) |

| Função Primária | Para transmitir 100% do torque do motor do disco de embreagem ao contraeixo da transmissão. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.