Bienvenido a esta guía experta sobre el Sistema de ventilación del cárter FAW, a critical emissions and engine-protection component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 tractor semirremolque diésel. This system is essential for engine longevity.

El Sistema de ventilación del cárter FAW is designed to safely manage “explosión”—the high-pressure gases and oil mist that escape past the piston rings during combustion. If left unmanaged, this pressure would blow out engine seals and release harmful emissions.

This technical guide is an indispensable resource for fleet technicians and parts specialists. Deconstruiremos todo Sistema de ventilación del cárter FAW en sus unidades útiles más pequeñas, including the oil-gas separator, the oil return line, and all associated pipes, paréntesis, y sellos.

El corazón de la Sistema de ventilación del cárter FAW is the ‘Oil-Gas Separator Assembly’ (1014010-81D). Este es el “cerebro” de la operación. Blow-by gas from the crankcase (which is pushed up from the valve cover) is not just air; it’s a high-velocity mist of hot, atomized engine oil. This component is designed to “limpio” this gas.

Inside this assembly is a complex series of baffles or a “coalescing filter” elemento. As the oily mist is forced through this media, the tiny oil droplets “juntarse,” or merge, en más grande, gotas más pesadas. Esta es la función principal del Sistema de ventilación del cárter FAW. These heavy droplets then fall, under gravity, to the bottom of the separator’s collection bowl.

A failure of this separator, either through clogging or a media breach, es critico. Un obstruido Sistema de ventilación del cárter FAW will cause crankcase pressure to build, blowing out the main crankshaft seals. A breached filter will allow liquid engine oil to be sucked directly into the turbocharger, which can lead to high oil consumption, humo azul, and fouling of the intercooler and intake manifold.

Una vez que el Sistema de ventilación del cárter FAW has successfully captured the liquid oil, it must be returned to the engine. Este es un “circuito cerrado” sistema, meaning it recycles the oil instead of dumping it. This is handled by the ‘Oil-Gas Separator Return Pipe’ (1014019-81D).

This rigid, pre-bent pipe connects to the bottom of the separator (1014010-81D) and routes the collected oil back into the engine block, where it drains safely back into the main oil pan. This is an essential function for conserving oil.

Because this line is subject to intense engine vibration, it must be rigidly secured. This is the job of the ‘Return Pipe Bracket’ (1014027-81D). This bracket is secured to the engine block with a ‘Hex flange bolt’ (Q1841020), and then holds the return pipe firmly in place, preventing it from cracking due to fatigue. A failure here would turn the return line of the Sistema de ventilación del cárter FAW into a major oil leak.

After the oil is separated, el “limpio” gas (now mostly just combustion vapors and air) must be safely vented. Este es el “Positive Crankcase Ventilation” (PCV) función de la Sistema de ventilación del cárter FAW. The ‘Ventilation Pipe’ (1014017-81D) is the large hose or pipe that serves as the exit for these gases.

This pipe routes the gases from the separator outlet directly into the engine’s clean air intake, just *before* the turbocharger. The suction from the turbo creates a slight, constant vacuum on the crankcase. This negative pressure is highly desirable, as it actively “tira” the blow-by gases out of the crankcase, preventing pressure from building up and blowing out seals. This is the primary goal of the Sistema de ventilación del cárter FAW.

This is also a critical emissions control device. By routing these hydrocarbon-laden vapors back into the engine, they are re-burned during the normal combustion process instead of being vented to the atmosphere.

Like the return line, this pipe is secured by the ‘Ventilation Pipe Bracket’ (1014018-81D) and its ‘Hex flange bolt’ (Q1840820) to prevent vibration damage. The entire system is sealed with ‘Worm Drive Hose Clamps’ (CQ67622B y CQ67650B). A loose clamp here is a major problem, as it creates a “fuga de vacío” that allows dirty, *unfiltered* air to be sucked directly into the turbocharger, which will destroy the compressor wheel. A properly sealed Sistema de ventilación del cárter FAW is key to turbo longevity.

The main ‘Oil-Gas Separator Assembly’ (1014010-81D) must be securely mounted to the engine (often on the valve cover or side of the block) and perfectly sealed. This is the job of the ‘Gasket – Descanso’ (1014027-53D). This is a precision-cut gasket designed to seal the mounting flange of the separator.

A failure of this one gasket would cause two problems simultaneously: a messy oil leak from the crankcase, and a vacuum leak, permitiendo el Sistema de ventilación del cárter FAW to pull in unmetered air.

The separator assembly is secured by two ‘Connecting Bolt’ (1014014-81D) sujetadores. These bolts pass through the separator housing and thread into the engine, comprimiendo la 'Junta – Descanso’ to create the final, reliable seal for the Sistema de ventilación del cárter FAW. The correct torque on these bolts is essential to avoid cracking the separator housing or failing to seal the gasket.

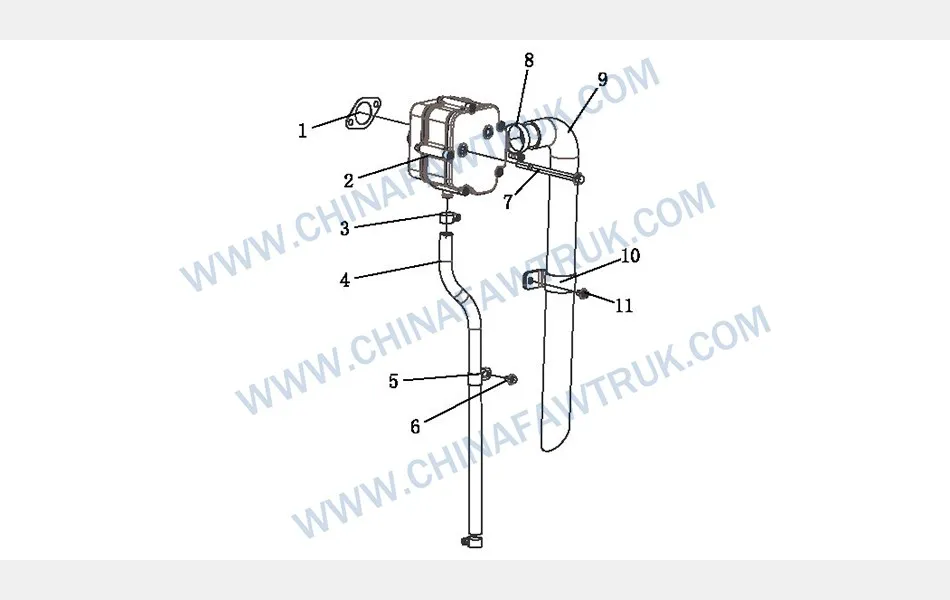

La siguiente tabla proporciona la información completa, detailed breakdown of all components identified in the ‘Crankcase Ventilation System’ diagrama para el tractor FAW CA4251P66K24T1A3E5. Un servicio completo de Sistema de ventilación del cárter FAW involves inspecting all hoses for cracks and replacing the main separator element.

| Marca | Número de pieza. | Nombre de la pieza | Cantidad |

|---|---|---|---|

| 1 | 1014027-53D | Empaquetadora – Descanso | 1 |

| 2 | 1014010-81D | Conjunto del separador de gas de petróleo | 1 |

| 3 | CQ67622B | Abrazadera de manguera con tornillo sin fin tipo B | 2 |

| 4 | 1014019-81D | Oil-Gas Separator Return Pipe | 1 |

| 5 | 1014027-81D | Return Pipe Bracket | 1 |

| 6 | Q1841020 | Perno de brida hexagonal, varilla gruesa (Tipo estándar) | 1 |

| 7 | 1014014-81D | Perno de conexión | 2 |

| 8 | CQ67650B | Abrazadera de manguera con tornillo sin fin tipo B | 1 |

| 9 | 1014017-81D | Ventilation Pipe | 1 |

| 10 | 1014018-81D | Ventilation Pipe Bracket | 1 |

| 11 | Q1840820 | Perno de brida hexagonal, varilla gruesa (Tipo estándar) | 1 |

Las especificaciones para el Sistema de ventilación del cárter FAW are defined by its function as a closed-loop oil-gas separator and emissions control system. todo el Sistema de ventilación del cárter FAW is vital for engine protection.

| Solicitud de vehículo | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Grupo de componentes | Sistema de ventilación del cárter FAW |

| Tipo de sistema | Closed-Loop, Positive Crankcase Ventilation (PCV) |

| Main Component | Conjunto del separador de gas de petróleo (1014010-81D) |

| Separation Method | Coalescing Filter / Baffle Labyrinth |

| Oil Circuit | Tubo de retorno de aceite (1014019-81D) to engine sump |

| Gas Circuit | Ventilation Pipe (1014017-81D) to turbocharger intake |

| Junta principal | Empaquetadora – Descanso (1014027-53D) |

| Función primaria | Prevent crankcase pressure, protect seals, recycle oil, reducir las emisiones. |

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.