Welcome to this expert guide on the FAW Crankcase Ventilation System, a critical emissions and engine-protection component for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This system is essential for engine longevity.

The FAW Crankcase Ventilation System is designed to safely manage “blow-by”—the high-pressure gases and oil mist that escape past the piston rings during combustion. If left unmanaged, this pressure would blow out engine seals and release harmful emissions.

This technical guide is an indispensable resource for fleet technicians and parts specialists. We will deconstruct the entire FAW Crankcase Ventilation System into its smallest serviceable units, including the oil-gas separator, the oil return line, and all associated pipes, brackets, and seals.

The heart of the FAW Crankcase Ventilation System is the ‘Oil-Gas Separator Assembly’ (1014010-81D). This is the “brain” of the operation. Blow-by gas from the crankcase (which is pushed up from the valve cover) is not just air; it’s a high-velocity mist of hot, atomized engine oil. This component is designed to “clean” this gas.

Inside this assembly is a complex series of baffles or a “coalescing filter” element. As the oily mist is forced through this media, the tiny oil droplets “coalesce,” or merge, into larger, heavier droplets. This is the primary function of the FAW Crankcase Ventilation System. These heavy droplets then fall, under gravity, to the bottom of the separator’s collection bowl.

A failure of this separator, either through clogging or a media breach, is critical. A clogged FAW Crankcase Ventilation System will cause crankcase pressure to build, blowing out the main crankshaft seals. A breached filter will allow liquid engine oil to be sucked directly into the turbocharger, which can lead to high oil consumption, blue smoke, and fouling of the intercooler and intake manifold.

Once the FAW Crankcase Ventilation System has successfully captured the liquid oil, it must be returned to the engine. This is a “closed-loop” system, meaning it recycles the oil instead of dumping it. This is handled by the ‘Oil-Gas Separator Return Pipe’ (1014019-81D).

This rigid, pre-bent pipe connects to the bottom of the separator (1014010-81D) and routes the collected oil back into the engine block, where it drains safely back into the main oil pan. This is an essential function for conserving oil.

Because this line is subject to intense engine vibration, it must be rigidly secured. This is the job of the ‘Return Pipe Bracket’ (1014027-81D). This bracket is secured to the engine block with a ‘Hex flange bolt’ (Q1841020), and then holds the return pipe firmly in place, preventing it from cracking due to fatigue. A failure here would turn the return line of the FAW Crankcase Ventilation System into a major oil leak.

After the oil is separated, the “clean” gas (now mostly just combustion vapors and air) must be safely vented. This is the “Positive Crankcase Ventilation” (PCV) function of the FAW Crankcase Ventilation System. The ‘Ventilation Pipe’ (1014017-81D) is the large hose or pipe that serves as the exit for these gases.

This pipe routes the gases from the separator outlet directly into the engine’s clean air intake, just *before* the turbocharger. The suction from the turbo creates a slight, constant vacuum on the crankcase. This negative pressure is highly desirable, as it actively “pulls” the blow-by gases out of the crankcase, preventing pressure from building up and blowing out seals. This is the primary goal of the FAW Crankcase Ventilation System.

This is also a critical emissions control device. By routing these hydrocarbon-laden vapors back into the engine, they are re-burned during the normal combustion process instead of being vented to the atmosphere.

Like the return line, this pipe is secured by the ‘Ventilation Pipe Bracket’ (1014018-81D) and its ‘Hex flange bolt’ (Q1840820) to prevent vibration damage. The entire system is sealed with ‘Worm Drive Hose Clamps’ (CQ67622B and CQ67650B). A loose clamp here is a major problem, as it creates a “vacuum leak” that allows dirty, *unfiltered* air to be sucked directly into the turbocharger, which will destroy the compressor wheel. A properly sealed FAW Crankcase Ventilation System is key to turbo longevity.

The main ‘Oil-Gas Separator Assembly’ (1014010-81D) must be securely mounted to the engine (often on the valve cover or side of the block) and perfectly sealed. This is the job of the ‘Gasket – Breather’ (1014027-53D). This is a precision-cut gasket designed to seal the mounting flange of the separator.

A failure of this one gasket would cause two problems simultaneously: a messy oil leak from the crankcase, and a vacuum leak, allowing the FAW Crankcase Ventilation System to pull in unmetered air.

The separator assembly is secured by two ‘Connecting Bolt’ (1014014-81D) fasteners. These bolts pass through the separator housing and thread into the engine, compressing the ‘Gasket – Breather’ to create the final, reliable seal for the FAW Crankcase Ventilation System. The correct torque on these bolts is essential to avoid cracking the separator housing or failing to seal the gasket.

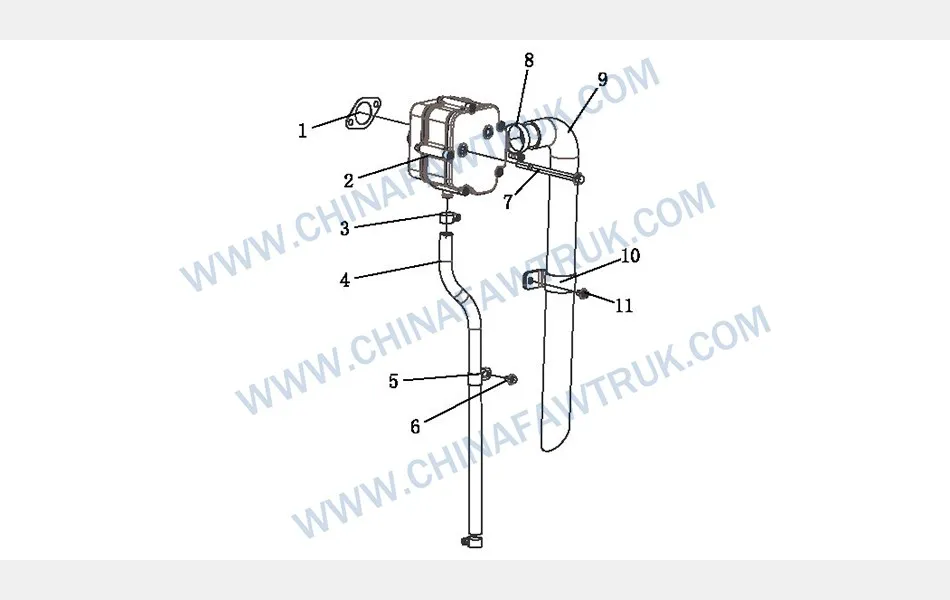

The following table provides the complete, detailed breakdown of all components identified in the ‘Crankcase Ventilation System’ diagram for the FAW CA4251P66K24T1A3E5 tractor. A complete service of the FAW Crankcase Ventilation System involves inspecting all hoses for cracks and replacing the main separator element.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 1014027-53D | Gasket – Breather | 1 |

| 2 | 1014010-81D | Oil-Gas Separator Assembly | 1 |

| 3 | CQ67622B | Worm Drive Hose Clamp B-Type | 2 |

| 4 | 1014019-81D | Oil-Gas Separator Return Pipe | 1 |

| 5 | 1014027-81D | Return Pipe Bracket | 1 |

| 6 | Q1841020 | Hex flange bolt, coarse rod (Standard Type) | 1 |

| 7 | 1014014-81D | Connecting Bolt | 2 |

| 8 | CQ67650B | Worm Drive Hose Clamp B-Type | 1 |

| 9 | 1014017-81D | Ventilation Pipe | 1 |

| 10 | 1014018-81D | Ventilation Pipe Bracket | 1 |

| 11 | Q1840820 | Hex flange bolt, coarse rod (Standard Type) | 1 |

The specifications for the FAW Crankcase Ventilation System are defined by its function as a closed-loop oil-gas separator and emissions control system. The entire FAW Crankcase Ventilation System is vital for engine protection.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Crankcase Ventilation System |

| System Type | Closed-Loop, Positive Crankcase Ventilation (PCV) |

| Main Component | Oil-Gas Separator Assembly (1014010-81D) |

| Separation Method | Coalescing Filter / Baffle Labyrinth |

| Oil Circuit | Oil Return Pipe (1014019-81D) to engine sump |

| Gas Circuit | Ventilation Pipe (1014017-81D) to turbocharger intake |

| Main Gasket | Gasket – Breather (1014027-53D) |

| Primary Function | Prevent crankcase pressure, protect seals, recycle oil, reduce emissions. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.