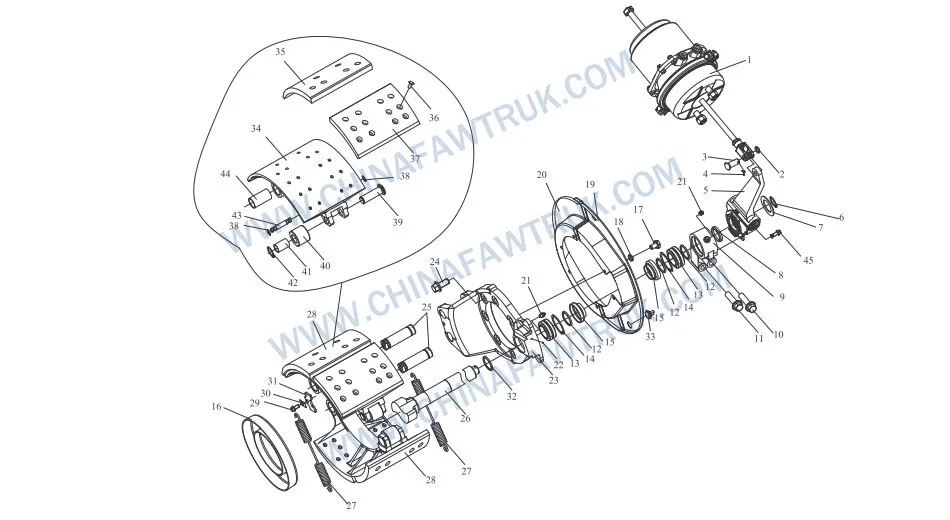

FAW Russian Centre-Left Brake Assembly: Engineering 45 Strategic Components for Tandem Axle Stability

The FAW Russian Centre-Left Brake assembly is the primary deceleration unit for the forward drive axle of the rear bogie on the CA3250P66K24L1TE5Z dump truck. Distinct from the rear-most brakes, the FAW Russian Centre-Left Brake must accommodate the unique suspension articulation and inter-axle driveshaft geometry of the middle axle. Engineered for the Siberian mining sector, this assembly integrates specialized camshaft bracketing and heavy-duty spring actuators to deliver consistent stopping power in temperatures as low as -50°C. This guide deconstructs the friction architecture, actuation logic, and mounting precision that define the FAW Russian Centre-Left Brake.

FAW Russian Centre-Left Brake

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3530035-896-C00 | Middle Axle Left Spring Cylinder with Quick Connector Assy | 1 |

| 2 | Q40114 | Washer | 2 |

| 3 | Q5101438 | Flat Head Pin | 2 |

| 4 | Q5003025 | Cotter Pin | 2 |

| 5 | 3503205-A0E | Middle Axle Left Brake Adjuster Arm Assembly | 1 |

| 6 | Q43138 | Shaft Snap Ring | 2 |

| 7 | 3501156A392 | Brake Adjustment Shim | 2 |

| 8 | 3502123-A0E | Spacer – Camshaft Bracket | 2 |

| 9 | 3503127-A0E | Middle Axle Left Camshaft Bracket | 1 |

| 10 | 3503038-A0E | Middle Axle Camshaft Bracket Locking Bolt | 2 |

| 11 | 3503039-A0E | Middle Axle Camshaft Bracket Locking Bolt | 2 |

| 12 | 3502153-A0E | Oil Seal – Camshaft Bracket | 6 |

| 13 | 3502135-A0E | Camshaft Joint Bearing Assembly | 4 |

| 14 | Q43062 | Hole Snap Ring | 4 |

| 15 | 3502124-A0E | Seat – Oil Seal | 4 |

| 16 | 3502432-A0E | Oil Deflector 2 | 2 |

| 17 | CQ1500812 | Hexagon Head Bolt | 12 |

| 18 | Q40308 | Spring Washer | 12 |

| 19 | 3502031-A0E | Rear Brake Rear Dust Shield | 2 |

| 20 | 3502032-A0E | Rear Brake Front Dust Shield | 2 |

| 21 | CQ70001 | Straight Grease Fitting | 4 |

| 22 | Q966555 | Steel Ball | 2 |

| 23 | 3502021-A0E | Rear Brake Bracket | 2 |

| 24 | 3502038-487 | Locking Bolt – For Brake Bracket | 14 |

| 25 | 3502086-A6E | Rear Brake Shoe Axle / Anchor Pin | 4 |

| 26 | 3502151-A6E | Rear Left Brake Camshaft (Middle Axle Application) | 1 |

| 27 | 3502436-A0E | Return Spring | 4 |

| 28 | 3502375-A6E | Rear Brake Shoe with Roller Assembly | 4 |

| 29 | CQ1501016 | Hexagon Head Bolt | 2 |

| 30 | 3501087-4E | Lock Plate – Brake Shoe Axle Retainer Bolt | 2 |

| 31 | 3502087-A6E | Brake Shoe Axle Retainer Plate | 2 |

| 32 | 3501029-A0S | Oil Seal – Brake Camshaft | 2 |

| 33 | 3501034-02 | Plug – Dust Shield Inspection Hole | 4 |

| 34 | 3502391-A6E | Rear Brake Shoe | 4 |

| 35 | 3502406-A6E | Rear Friction Lining I | 4 |

| 36 | 3502407-A6E | Rear Friction Lining II | 4 |

| 37 | 3502408-A0E | Rivet – Brake Lining | 104 |

| 38 | Q43112 | Shaft Snap Ring | 8 |

| 39 | 3502394-A0E | Roller Shaft | 4 |

| 40 | 3502392-A0E | Brake Shoe Roller | 4 |

| 41 | 3502393-A0E | Roller Bushing | 4 |

| 42 | Q43122 | Shaft Snap Ring | 4 |

| 43 | 3502398-A0E | Return Spring Anchor Pin | 4 |

| 44 | 3501396-A0S | Bushing – Brake Shoe | 4 |

| 45 | CQ1500820 | Hexagon Head Bolt | 2 |

| – | Q40308 | Spring Washer | 2 |

Mid-Axle Deceleration Dynamics

The FAW Russian Centre-Left Brake serves a specific role within the 6×6 drivetrain configuration. Located on the leading drive axle (middle axle), this brake unit experiences unique torsional loads due to the inter-axle differential and the articulation of the walking beam suspension. The assembly features the robust Middle Axle Left Spring Cylinder with Quick Connector Assy (Part No. 3530035-896-C00), which provides both service braking force and emergency parking capability. This dual-function actuator is essential for holding the vehicle on the steep, icy inclines of open-pit mines.

Unlike standard rear brakes, the FAW Russian Centre-Left Brake utilizes specific mounting hardware like the Middle Axle Left Camshaft Bracket (Part No. 3503127-A0E). This bracket is designed to clear the complex linkage of the tandem suspension while providing a rigid fulcrum for the camshaft. Securement is achieved via high-tensile Locking Bolt – Camshaft Bracket units (Part No. 3503038-A0E and 3503039-A0E), which prevent the bracket from shifting under the severe vibration typical of off-road dump truck operations.

The friction strategy remains consistent with the rear axle to ensure balanced braking. The FAW Russian Centre-Left Brake employs the same 410mm drum and Rear Friction Lining set (Part No. 3502406-A6E / 3502407-A6E) as the rear-most axle. This commonality simplifies parts inventory for fleet managers. However, the actuation timing is fine-tuned via the Middle Axle Left Brake Adjuster Arm Assembly (Part No. 3503205-A0E), ensuring that the middle and rear axles engage simultaneously to prevent wheel lockup and tire flat-spotting.

Camshaft and Bearing Architecture

The core actuation mechanism of the FAW Russian Centre-Left Brake is the Rear Left Brake Camshaft (Part No. 3502151-A6E). Even though it is installed on the middle axle, it shares the geometry of the rear left unit, simplifying the supply chain. This S-cam converts the linear motion of the slack adjuster into the rotary force needed to spread the brake shoes. Critical to its operation is the Camshaft Joint Bearing Assembly (Part No. 3502135-A0E). This spherical bearing accommodates the slight misalignment caused by axle flex under heavy loads, preventing the camshaft from binding.

Protection of this mechanism is provided by a multi-layered sealing system. The Oil Seal – Camshaft Bracket (Part No. 3502153-A0E) works in conjunction with the Seat – Oil Seal (Part No. 3502124-A0E) to keep road grime and water out of the bearing housing. In the FAW Russian Centre-Left Brake, maintaining these seals is vital; ingress of abrasive silica dust from mining roads can destroy the camshaft journals in weeks.

Precise end-play adjustment is managed by the Brake Adjustment Shim (Part No. 3501156A392) and Spacer – Camshaft Bracket (Part No. 3502123-A0E). These components ensure the camshaft remains centered within the drum, preventing the S-head from contacting the spider bracket. Correct shimming during assembly or maintenance of the FAW Russian Centre-Left Brake ensures that the automatic slack adjuster functions correctly, maintaining the optimal lining-to-drum clearance.

Friction Components and Environmental Shielding

The friction generation in the FAW Russian Centre-Left Brake is handled by the massive Rear Brake Shoe (Part No. 3502391-A6E). These shoes are retained by the Rear Brake Shoe Axle / Anchor Pin (Part No. 3502086-A6E) and the Return Spring (Part No. 3502436-A0E). The return springs are made from heavy-gauge wire to ensure the shoes retract fully, preventing drag that could overheat the wheel end. Overheating is a major risk in winter, as it can melt snow which then refreezes into ice on the linings when the truck parks.

To mitigate environmental contamination, the FAW Russian Centre-Left Brake features the Rear Brake Rear Dust Shield (Part No. 3502031-A0E) and Rear Brake Front Dust Shield (Part No. 3502032-A0E). These interlocking plates form a barrier against mud and rocks. The inspection holes are sealed with the Plug – Dust Shield Inspection Hole (Part No. 3501034-02), allowing mechanics to check lining wear without exposing the drum interior to the elements.

The connection between the shoes and the S-cam is smoothed by the Rear Brake Shoe with Roller Assembly (Part No. 3502375-A6E). This includes the Brake Shoe Roller (Part No. 3502392-A0E) and Roller Shaft (Part No. 3502394-A0E). These rollers reduce friction and hysteresis in the actuation cycle, providing the driver with linear and predictable braking response. The Roller Bushing (Part No. 3502393-A0E) is designed to operate without seizing even when the grease viscosity increases in extreme cold.

Maintenance Access and Component Retention

Reliability of the FAW Russian Centre-Left Brake is ensured through robust retention methods. The anchor pins are secured by the Brake Shoe Axle Retainer Plate (Part No. 3502087-A6E) and locked with the Lock Plate (Part No. 3501087-4E). This redundant locking system prevents the pins from walking out under the torsional vibration of braking. Furthermore, numerous Shaft Snap Ring units (Part No. Q43112 and Q43122) secure the rollers and pivot points, ensuring the internal geometry remains fixed.

Routine maintenance is facilitated by the Straight Grease Fitting (Part No. CQ70001). Located on the camshaft bracket and slack adjuster, these fittings allow fresh lubricant to be purged into critical wear areas. In the FAW Russian Centre-Left Brake, regular greasing pushes out water and old grease, extending the life of the Bushing – Brake Shoe (Part No. 3501396-A0S) and camshaft bearings.

The structural backbone, the Rear Brake Bracket (Part No. 3502021-A0E), is bolted to the axle housing with Locking Bolt – For Brake Bracket (Part No. 3502038-487). These bolts are critical safety items; they must be torqued to specific values to withstand the shear forces of braking. By strictly adhering to the parts list for the FAW Russian Centre-Left Brake, utilizing genuine Rivet (Part No. 3502408-A0E) and linings, operators ensure the continued safety and performance of their heavy-duty fleet.

Conclusion: The Linchpin of the Tandem Axle

The FAW Russian Centre-Left Brake is a specialized assembly that bridges the gap between standard rear braking and the specific needs of a tandem drive bogie. With 45 strategic components, including the dedicated Middle Axle Left Spring Cylinder and reinforced Middle Axle Left Camshaft Bracket, it offers the durability required for Arctic operations. Its design ensures that braking force is applied evenly across the bogie, preventing tire hop and suspension damage.

For fleet maintenance teams, understanding the specific part numbers for the middle axle, such as the unique slack adjuster and bracketry, is essential. While it shares friction components with the rear axle, the actuation hardware is distinct. By maintaining the FAW Russian Centre-Left Brake with genuine FAW parts, operators guarantee maximum uptime and safety for their vehicles in the world’s toughest working environments.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.