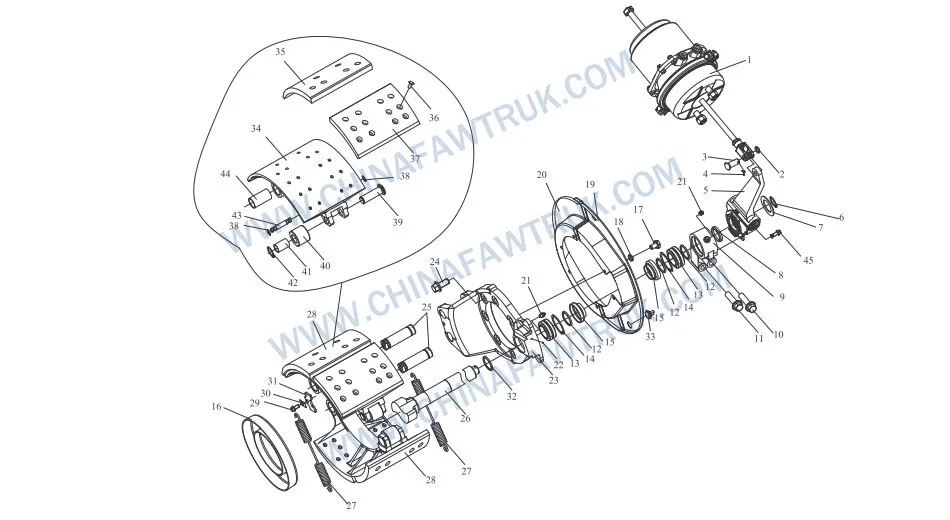

FAW مجموعة الفرامل الروسية الوسطى اليسرى: هندسة 45 المكونات الإستراتيجية لاستقرار المحور الترادفي

ال FAW الفرامل المركزية اليسرى الروسية التجميع هو وحدة التباطؤ الأساسية لمحور الدفع الأمامي للعربة الخلفية في الشاحنة القلابة CA3250P66K24L1TE5Z. مميزة عن معظم الفرامل الخلفية, ال FAW الفرامل المركزية اليسرى الروسية يجب أن يستوعب مفصل التعليق الفريد وهندسة عمود الإدارة بين المحاور للمحور الأوسط. مصممة لقطاع التعدين السيبيري, يدمج هذا التجميع دعامات عمود الكامات المتخصصة ومحركات زنبركية شديدة التحمل لتوفير قوة إيقاف ثابتة في درجات حرارة منخفضة تصل إلى -50 درجة مئوية. هذا الدليل يفكك بنية الاحتكاك, منطق التشغيل, ودقة التركيب التي تحدد FAW الفرامل المركزية اليسرى الروسية.

FAW الفرامل المركزية اليسرى الروسية

| لا. |

رقم الجزء |

جزء اسم |

الكمية |

| 1 | 3530035-896-C00 | المحور الأوسط أسطوانة الربيع اليسرى مع موصل سريع عاصي | 1 |

| 2 | س40114 | غسالة | 2 |

| 3 | Q5101438 | دبوس رأس مسطح | 2 |

| 4 | س5003025 | دبوس كوتر | 2 |

| 5 | 3503205-A0E | مجموعة ذراع ضبط الفرامل للمحور الأوسط | 1 |

| 6 | Q43138 | رمح المفاجئة الدائري | 2 |

| 7 | 3501156A392 | تعديل الفرامل الرقائق | 2 |

| 8 | 3502123-A0E | فاصل – قوس عمود الحدبات | 2 |

| 9 | 3503127-A0E | قوس عمود الحدبات الأيسر للمحور الأوسط | 1 |

| 10 | 3503038-A0E | مسمار قفل دعامة عمود الحدبات للمحور الأوسط | 2 |

| 11 | 3503039-A0E | مسمار قفل دعامة عمود الحدبات للمحور الأوسط | 2 |

| 12 | 3502153-A0E | ختم النفط – قوس عمود الحدبات | 6 |

| 13 | 3502135-A0E | عمود الحدبات المشترك تحمل الجمعية | 4 |

| 14 | س43062 | ثقب المفاجئة الدائري | 4 |

| 15 | 3502124-A0E | مقعد – ختم النفط | 4 |

| 16 | 3502432-A0E | عاكس الزيت 2 | 2 |

| 17 | CQ1500812 | مسدس رئيس الترباس | 12 |

| 18 | س40308 | غسالة الربيع | 12 |

| 19 | 3502031-A0E | درع الغبار الخلفي للفرامل الخلفية | 2 |

| 20 | 3502032-A0E | درع الغبار الأمامي للفرامل الخلفية | 2 |

| 21 | CQ70001 | تركيب الشحوم المستقيم | 4 |

| 22 | Q966555 | الكرة الفولاذية | 2 |

| 23 | 3502021-A0E | قوس الفرامل الخلفية | 2 |

| 24 | 3502038-487 | قفل الترباس – لقوس الفرامل | 14 |

| 25 | 3502086-أ6ه | محور حذاء الفرامل الخلفي / دبوس مرساة | 4 |

| 26 | 3502151-أ6ه | عمود الحدبات الفرامل الخلفية اليسرى (تطبيق المحور الأوسط) | 1 |

| 27 | 3502436-A0E | عودة الربيع | 4 |

| 28 | 3502375-أ6ه | حذاء الفرامل الخلفي مع مجموعة الأسطوانة | 4 |

| 29 | CQ1501016 | مسدس رئيس الترباس | 2 |

| 30 | 3501087-4ه | لوحة القفل – مسمار تثبيت محور الفرامل | 2 |

| 31 | 3502087-أ6ه | لوحة تثبيت محور حذاء الفرامل | 2 |

| 32 | 3501029-أ0س | ختم النفط – عمود الحدبات الفرامل | 2 |

| 33 | 3501034-02 | سدادة – فتحة فحص درع الغبار | 4 |

| 34 | 3502391-أ6ه | حذاء الفرامل الخلفية | 4 |

| 35 | 3502406-أ6ه | بطانة الاحتكاك الخلفية I | 4 |

| 36 | 3502407-أ6ه | بطانة الاحتكاك الخلفية II | 4 |

| 37 | 3502408-A0E | برشام – بطانة الفرامل | 104 |

| 38 | س43112 | رمح المفاجئة الدائري | 8 |

| 39 | 3502394-A0E | رمح الأسطوانة | 4 |

| 40 | 3502392-A0E | بكرة حذاء الفرامل | 4 |

| 41 | 3502393-A0E | جلبة الأسطوانة | 4 |

| 42 | Q43122 | رمح المفاجئة الدائري | 4 |

| 43 | 3502398-A0E | عودة الربيع مرساة دبوس | 4 |

| 44 | 3501396-أ0س | جلبة – حذاء الفرامل | 4 |

| 45 | CQ1500820 | مسدس رئيس الترباس | 2 |

| – | س40308 | غسالة الربيع | 2 |

ديناميكيات تباطؤ المحور الأوسط

ال FAW الفرامل المركزية اليسرى الروسية يخدم دورا محددا في 6×6 تكوين نظام الدفع. تقع على محور القيادة الرئيسي (المحور الأوسط), تواجه وحدة الفرامل هذه أحمالًا الالتوائية فريدة من نوعها بسبب الترس التفاضلي بين المحاور ومفصلية تعليق شعاع المشي. يتميز التجميع بالقوة المحور الأوسط أسطوانة الربيع اليسرى مع موصل سريع عاصي (الجزء لا. 3530035-896-C00), والذي يوفر قوة فرملة الخدمة والقدرة على ركن السيارة في حالات الطوارئ. يعد هذا المحرك ثنائي الوظيفة ضروريًا لتثبيت السيارة على المنحدر, المنحدرات الجليدية للمناجم المفتوحة.

على عكس الفرامل الخلفية القياسية, ال FAW الفرامل المركزية اليسرى الروسية يستخدم أجهزة تركيب محددة مثل قوس عمود الحدبات الأيسر للمحور الأوسط (الجزء لا. 3503127-A0E). تم تصميم هذه الدعامة لمسح الوصلة المعقدة لنظام التعليق الترادفي مع توفير نقطة ارتكاز صلبة لعمود الكامات. يتم تحقيق التأمين عن طريق الشد العالي قفل الترباس – قوس عمود الحدبات وحدات (الجزء لا. 3503038-A0E و3503039-A0E), والتي تمنع الدعامة من التحرك تحت الاهتزاز الشديد المعتاد لعمليات الشاحنات القلابة على الطرق الوعرة.

تظل استراتيجية الاحتكاك متسقة مع المحور الخلفي لضمان الكبح المتوازن. ال FAW الفرامل المركزية اليسرى الروسية يستخدم نفس الأسطوانة مقاس 410 مم و بطانة الاحتكاك الخلفية تعيين (الجزء لا. 3502406-أ6ه / 3502407-أ6ه) كالمحور الخلفي. تعمل هذه القواسم المشتركة على تبسيط عملية جرد قطع الغيار لمديري الأساطيل. لكن, يتم ضبط توقيت التشغيل بدقة عبر مجموعة ذراع ضبط الفرامل للمحور الأوسط (الجزء لا. 3503205-A0E), التأكد من تعشيق المحورين الأوسط والخلفي في وقت واحد لمنع انغلاق العجلات وبقع الإطارات المسطحة.

عمود الحدبات وتحمل العمارة

آلية التشغيل الأساسية لل FAW الفرامل المركزية اليسرى الروسية هو عمود الحدبات الفرامل الخلفية اليسرى (الجزء لا. 3502151-أ6ه). على الرغم من تثبيته على المحور الأوسط, تشترك في هندسة الوحدة الخلفية اليسرى, تبسيط سلسلة التوريد. تقوم كاميرا S هذه بتحويل الحركة الخطية لضابط الركود إلى القوة الدوارة اللازمة لتوزيع أحذية الفرامل. أمر بالغ الأهمية لعملها هو عمود الحدبات المشترك تحمل الجمعية (الجزء لا. 3502135-A0E). يستوعب هذا المحمل الكروي المحاذاة الطفيفة الناتجة عن انثناء المحور تحت الأحمال الثقيلة, منع عمود الحدبات من الربط.

يتم توفير حماية هذه الآلية من خلال نظام مانع للتسرب متعدد الطبقات. ال ختم النفط – قوس عمود الحدبات (الجزء لا. 3502153-A0E) يعمل بالاشتراك مع مقعد – ختم النفط (الجزء لا. 3502124-A0E) لإبعاد أوساخ الطريق والمياه عن مبيت المحمل. في FAW الفرامل المركزية اليسرى الروسية, الحفاظ على هذه الأختام أمر حيوي; يمكن أن يؤدي دخول غبار السيليكا الكاشطة من طرق التعدين إلى تدمير مجلات عمود الحدبات في غضون أسابيع.

تتم إدارة التعديل الدقيق للتشغيل النهائي بواسطة تعديل الفرامل الرقائق (الجزء لا. 3501156A392) و فاصل – قوس عمود الحدبات (الجزء لا. 3502123-A0E). تضمن هذه المكونات بقاء عمود الكامات متمركزًا داخل الأسطوانة, منع رأس S من الاتصال بقوس العنكبوت. الحشو الصحيح أثناء التجميع أو الصيانة FAW الفرامل المركزية اليسرى الروسية يضمن أن أداة ضبط الركود التلقائي تعمل بشكل صحيح, الحفاظ على الخلوص الأمثل من البطانة إلى الأسطوانة.

مكونات الاحتكاك والتدريع البيئي

جيل الاحتكاك في FAW الفرامل المركزية اليسرى الروسية يتم التعامل معها من قبل ضخمة حذاء الفرامل الخلفية (الجزء لا. 3502391-أ6ه). يتم الاحتفاظ بهذه الأحذية من قبل محور حذاء الفرامل الخلفي / دبوس مرساة (الجزء لا. 3502086-أ6ه) و عودة الربيع (الجزء لا. 3502436-A0E). نوابض العودة مصنوعة من سلك ثقيل لضمان سحب الحذاء بالكامل, منع السحب الذي قد يؤدي إلى ارتفاع درجة حرارة طرف العجلة. ارتفاع درجة الحرارة هو خطر كبير في فصل الشتاء, لأنه يمكن أن يذيب الثلج الذي يتجمد مرة أخرى ويتحول إلى جليد على البطانات عندما تتوقف الشاحنة.

للتخفيف من التلوث البيئي, ال FAW الفرامل المركزية اليسرى الروسية يتميز درع الغبار الخلفي للفرامل الخلفية (الجزء لا. 3502031-A0E) و درع الغبار الأمامي للفرامل الخلفية (الجزء لا. 3502032-A0E). تشكل هذه الصفائح المتشابكة حاجزًا ضد الطين والصخور. يتم إغلاق فتحات التفتيش باستخدام سدادة – فتحة فحص درع الغبار (الجزء لا. 3501034-02), السماح للميكانيكيين بالتحقق من تآكل البطانة دون تعريض الجزء الداخلي للأسطوانة للعناصر.

يتم تسهيل الاتصال بين الحذاء وكاميرا S بواسطة حذاء الفرامل الخلفي مع مجموعة الأسطوانة (الجزء لا. 3502375-أ6ه). وهذا يشمل بكرة حذاء الفرامل (الجزء لا. 3502392-A0E) و رمح الأسطوانة (الجزء لا. 3502394-A0E). تعمل هذه الأسطوانات على تقليل الاحتكاك والتباطؤ في دورة التشغيل, تزويد السائق باستجابة فرملة خطية ويمكن التنبؤ بها. ال جلبة الأسطوانة (الجزء لا. 3502393-A0E) تم تصميمه للعمل دون توقف حتى عندما تزيد لزوجة الشحوم في البرد القارس.

الوصول إلى الصيانة والاحتفاظ بالمكونات

موثوقية FAW الفرامل المركزية اليسرى الروسية يتم ضمانه من خلال أساليب الاحتفاظ القوية. يتم تأمين دبابيس المرساة بواسطة لوحة تثبيت محور حذاء الفرامل (الجزء لا. 3502087-أ6ه) ومقفل مع لوحة القفل (الجزء لا. 3501087-4ه). يمنع نظام القفل الزائد هذا المسامير من الخروج تحت الاهتزاز الالتوائي للفرملة. بالإضافة إلى, عديد رمح المفاجئة الدائري وحدات (الجزء لا. Q43112 و Q43122) تأمين بكرات والنقاط المحورية, ضمان بقاء الهندسة الداخلية ثابتة.

يتم تسهيل الصيانة الروتينية من خلال تركيب الشحوم المستقيم (الجزء لا. CQ70001). تقع على قوس عمود الحدبات وضابط الركود, تسمح هذه التركيبات بتطهير مواد التشحيم الجديدة في مناطق التآكل الحرجة. في FAW الفرامل المركزية اليسرى الروسية, التشحيم المنتظم يدفع الماء والشحوم القديمة, إطالة عمر جلبة – حذاء الفرامل (الجزء لا. 3501396-أ0س) ومحامل عمود الحدبات.

العمود الفقري الهيكلي, ال قوس الفرامل الخلفية (الجزء لا. 3502021-A0E), يتم تثبيته على مبيت المحور باستخدام قفل الترباس – لقوس الفرامل (الجزء لا. 3502038-487). هذه البراغي هي عناصر السلامة الهامة; يجب أن يتم عزمها إلى قيم محددة لتحمل قوى القص الناتجة عن الكبح. من خلال الالتزام الصارم بقائمة الأجزاء الخاصة بـ FAW الفرامل المركزية اليسرى الروسية, باستخدام حقيقية برشام (الجزء لا. 3502408-A0E) وبطانات, يضمن المشغلون استمرار سلامة وأداء أسطولهم الثقيل.

خاتمة: محور المحور الترادفي

ال FAW الفرامل المركزية اليسرى الروسية عبارة عن مجموعة متخصصة تعمل على سد الفجوة بين المكابح الخلفية القياسية والاحتياجات المحددة لعربة القيادة الترادفية. مع 45 المكونات الاستراتيجية, بما في ذلك المخصصة المحور الأوسط الأيسر اسطوانة الربيع وتعزيزها قوس عمود الحدبات الأيسر للمحور الأوسط, فهو يوفر المتانة المطلوبة لعمليات القطب الشمالي. يضمن تصميمه تطبيق قوة الكبح بشكل متساوٍ عبر العربة, منع قفز الإطارات وتلف التعليق.

لفرق صيانة الأسطول, فهم أرقام الأجزاء المحددة للمحور الأوسط, مثل أداة ضبط الركود الفريدة والأقواس, أمر ضروري. بينما تشترك في مكونات الاحتكاك مع المحور الخلفي, أجهزة التشغيل متميزة. بالمحافظة على FAW الفرامل المركزية اليسرى الروسية مع قطع غيار FAW الأصلية, يضمن المشغلون أقصى قدر من الجهوزية والسلامة لمركباتهم في أصعب بيئات العمل في العالم.

التعبئة والتغليف والخدمات اللوجستية

أجزاء فاو, بما في ذلك مجموعة كتلة الأسطوانة, يتم تعبئتها بعناية لضمان الولادة الآمنة. يتم تأمين كل مكون في مواد واقية لمنع الضرر أثناء النقل. تضمن الشبكة اللوجستية الشحنات في الوقت المناسب في جميع أنحاء العالم, دعم عمليات الصيانة الفعالة. فيما يلي صورة توضح العبوة القياسية لقطع غيار شاحنات FAW, إظهار الاهتمام بالتفاصيل في التعامل والتخزين.

يقلل أسلوب التغليف هذا من مخاطر التآكل أو التلف الناتج عن الصدمات, ضمان وصول أجزاء مثل FAW Cylinder Block Assembly في حالة ممتازة. يمكن للعملاء الاعتماد على الخدمات اللوجستية التي تقدمها FAW للحصول على الجودة والموثوقية المتسقة.