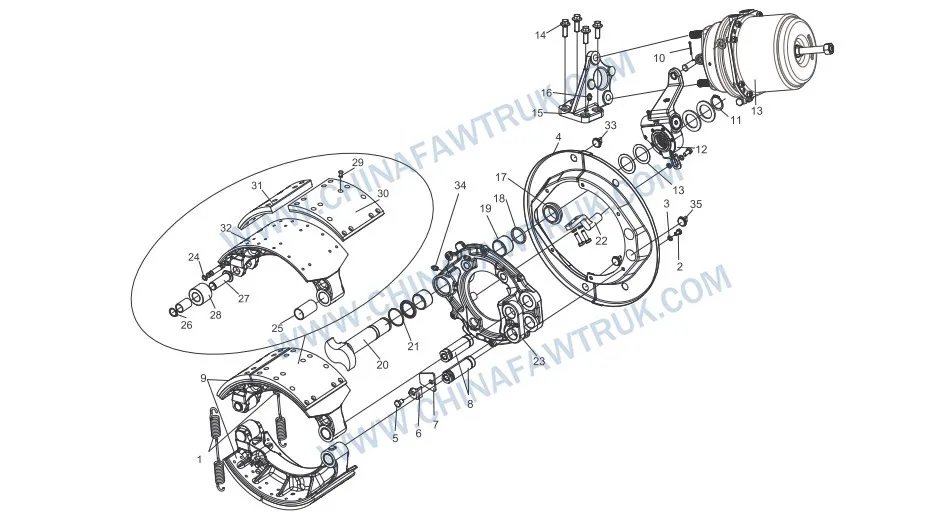

FAW Russian Front Right Brake Assembly: Engineering 53 Strategic Components for Balanced Arctic Deceleration

The FAW Russian Front Right Brake assembly is the pivotal counterpart in the steering axle deceleration system of the CA3250P66K24L1TE5Z dump truck. While mirroring the left-side unit in function, this assembly features unique geometry in its camshaft and adjuster mechanisms, specifically calibrated to ensure symmetrical braking forces on icy surfaces. Operating in the Russian Arctic requires the FAW Russian Front Right Brake to withstand thermal shocks from -50°C ambient temperatures to 400°C operating heat without fracturing or fading. This guide provides a granular analysis of the friction components, actuation logic, and structural mounting that define the FAW Russian Front Right Brake.

FAW Russian Front Right Brake

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3501436-820 | Return Spring | 2 |

| 2 | CQ1501016 | Hexagon Head Bolt | 3 |

| 3 | Q40310 | Spring Washer | 3 |

| 4 | 3501031-820 | Dust Shield / Dust Cover | 1 |

| 5 | CQ1501016 | Hexagon Head Bolt | 1 |

| 6 | 3501053-A0S | Lock Plate – Brake Shoe Axle Retainer | 1 |

| 7 | 3501052-A0S | Retainer Plate – Brake Shoe Axle | 1 |

| 8 | 3501051-820 | Front Brake Shoe Axle / Pin | 2 |

| 9 | 3501375-820 | Front Brake Shoe with Roller Assembly | 2 |

| 10 | Q40114 | Washer | 1 |

| – | Q5003025 | Cotter Pin | 1 |

| – | Q5101438 | Flat Head Pin | 1 |

| 11 | 3501251-A0S | Spacer – Brake Adjuster Arm | 1 |

| – | 3502252-A0R | Rear Brake Wear Indicator Washer | 1 |

| – | Q43138 | Shaft Snap Ring | 1 |

| 12 | 3501210-820-C00 | Front Right Automatic Adjuster Arm Assembly | 1 |

| – | CQ1500816 | Hexagon Head Bolt | 1 |

| – | Q40108 | Washer | 1 |

| – | Q40108 | Washer | As Req |

| 13 | 3530020-896-C00 | Spring Brake Chamber Assembly | 1 |

| 14 | Q1851450 | Hexagon Flange Bolt | 4 |

| 15 | 3501128-820 | Front Right Air Chamber Bracket | 1 |

| 16 | CQ70190 | Elbow Grease Fitting | 1 |

| 17 | 3501157-A0S | Spacer – Brake Camshaft | 1 |

| 18 | 3501156-A0S | Felt Seal Ring – Brake Camshaft | 1 |

| 19 | 3501028-A2S | Bushing – Brake Camshaft | 2 |

| 20 | 3501152-820 | Front Right Brake Camshaft | 1 |

| 21 | 3501029-A0S | Oil Seal – Brake Camshaft | 1 |

| – | 3501153-A0S | Washer – Brake Camshaft | 1 |

| 22 | 3501033-820 | Bracket | 1 |

| – | CQ1500820 | Hexagon Head Bolt | 2 |

| – | Q40308 | Spring Washer | 2 |

| 23 | 3501022-820 | Front Right Brake Bracket | 1 |

| 24 | 3502398-A0E | Return Spring Anchor Pin | 2 |

| – | Q43112 | Shaft Snap Ring | 4 |

| 25 | 3501396-A0S | Bushing – Front Brake Shoe | 2 |

| 26 | Q43122 | Shaft Snap Ring | 2 |

| 27 | 3502394-A0E | Roller Shaft | 2 |

| 28 | 3502392-A0E | Brake Shoe Roller | 2 |

| – | 3502393-A0E | Roller Bushing | 2 |

| 29 | 3502408-A0E | Rivet – Brake Lining | 32 |

| 30 | 3501406-820 | Front Brake Shoe Lining I | 2 |

| 31 | 3501407-820 | Front Brake Shoe Lining II | 2 |

| 32 | 3501391-820 | Front Brake Shoe | 2 |

| 33 | 3501034-02 | Plug – Dust Shield Inspection Hole | 2 |

| 34 | CQ70001 | Straight Grease Fitting | 1 |

| 35 | 3501034-820 | Plug | 2 |

Friction Mechanics: The Science of Stopping

At the heart of the FAW Russian Front Right Brake assembly lies the friction generation system. This relies on the Front Brake Shoe (Part No. 3501391-820), a rigid steel arc designed to carry the friction material. In this cold-weather specification, FAW utilizes a dual-lining approach with Front Brake Shoe Lining I (Part No. 3501406-820) and Front Brake Shoe Lining II (Part No. 3501407-820). These linings are bonded and riveted using the Rivet – Brake Lining (Part No. 3502408-A0E) to prevent delamination during extreme thermal cycling, which is common when braking hard in sub-zero ambient temperatures.

The movement of the shoes in the FAW Russian Front Right Brake is orchestrated by the Return Spring (Part No. 3501436-820). This component is critical; if it loses tension due to metal fatigue or cold brittleness, the shoes will drag against the drum, creating localized heat spots and glazing the linings. The FAW Russian Front Right Brake uses high-tensile wire for these springs to ensure rapid retraction. The shoes pivot on the Front Brake Shoe Axle / Pin (Part No. 3501051-820), secured by the Lock Plate – Brake Shoe Axle Retainer (Part No. 3501053-A0S), ensuring precise alignment under the immense torque loads of braking.

To reduce friction within the actuation mechanism itself, the FAW Russian Front Right Brake employs the Brake Shoe Roller (Part No. 3502392-A0E) and Roller Shaft (Part No. 3502394-A0E). These rollers minimize the physical resistance between the S-cam and the brake shoes, allowing for smoother modulation and preventing the “grabbing” sensation often felt in inferior drum brakes. The Roller Bushing (Part No. 3502393-A0E) is made from a self-lubricating composite to function even if the grease thickens in the Russian winter.

Actuation Logic: Asymmetric Engineering

The conversion of pneumatic pressure into mechanical force in the FAW Russian Front Right Brake is handled by the Front Right Brake Camshaft (Part No. 3501152-820). Unlike the left-side equivalent, this S-cam features a reverse helix profile, engineered to counteract the rotational torque of the right-side wheels during deceleration. It is driven by the Front Right Automatic Adjuster Arm Assembly (Part No. 3501210-820-C00), a crucial component that automatically maintains the optimal gap between the lining and the drum. Without this automatic adjustment, the FAW Russian Front Right Brake would require frequent manual intervention to maintain symmetrical stopping power.

The motive force is provided by the Spring Brake Chamber Assembly (Part No. 3530020-896-C00), mounted securely on the Front Right Air Chamber Bracket (Part No. 3501128-820). In the FAW Russian Front Right Brake system, this chamber is positioned to minimize exposure to road spray. The connection between the chamber and the bracket utilizes Hexagon Flange Bolt (Part No. Q1851450) fasteners, ensuring that the heavy air chamber does not shift under vibration, which could lead to binding in the pushrod and uneven wear on the FAW Russian Front Right Brake components.

Proper alignment of the camshaft is maintained by a series of spacers and washers, specifically the Spacer – Brake Camshaft (Part No. 3501157-A0S) and Washer – Brake Camshaft (Part No. 3501153-A0S). These components in the FAW Russian Front Right Brake assembly prevent lateral movement of the camshaft, ensuring that the S-head engages the rollers squarely. Any misalignment here results in accelerated wear of the Bushing – Brake Camshaft (Part No. 3501028-A2S) and reduced braking efficiency.

Structural Integrity and Environmental Protection

The foundation of the FAW Russian Front Right Brake is the Front Right Brake Bracket (Part No. 3501022-820), also known as the spider. This cast component bolts to the axle flange and supports the entire brake assembly. It is designed to handle the immense torque reaction generated when stopping a 30-ton loaded truck. Protecting the internal components of the FAW Russian Front Right Brake from the harsh external environment is the Dust Shield / Dust Cover (Part No. 3501031-820). This shield prevents mud, salt, and ice from entering the drum and contaminating the friction surfaces.

For inspection purposes, the dust shield on the FAW Russian Front Right Brake features access ports sealed with the Plug – Dust Shield Inspection Hole (Part No. 3501034-02). These plugs allow mechanics to check lining thickness without disassembling the wheel end. Ensuring these plugs are compliant and in place is vital; missing plugs allow abrasive road grit to enter the FAW Russian Front Right Brake, scoring the drum and destroying the Front Brake Shoe Lining prematurely.

Internal retention is managed by various snap rings, such as the Shaft Snap Ring (Part No. Q43112) used on the roller shafts. These small clips prevent critical pivot pins from migrating out of position. The FAW Russian Front Right Brake also utilizes the Lock Plate – Brake Shoe Axle Retainer (Part No. 3501053-A0S) as a secondary safety measure to keep the anchor pins fixed. This multi-layer retention strategy is a hallmark of the FAW Russian Front Right Brake safety design philosophy.

Lubrication and Maintenance Protocols

Longevity of the FAW Russian Front Right Brake is directly tied to lubrication. The assembly features accessible points like the Elbow Grease Fitting (Part No. CQ70190) and the Straight Grease Fitting (Part No. CQ70001). These allow fresh grease to be purged into the camshaft bushings and slack adjuster. In the FAW Russian Front Right Brake, keeping these points greased flushes out contaminants and creates a barrier against moisture ingress, which is the primary cause of seized brakes in winter.

Sealing the grease within the working areas is the job of the Oil Seal – Brake Camshaft (Part No. 3501029-A0S) and the Felt Seal Ring – Brake Camshaft (Part No. 3501156-A0S). The felt ring acts as a wiper, preventing coarse dirt from reaching the inner seal. If these seals fail on the FAW Russian Front Right Brake, grease can leak onto the brake linings, causing a catastrophic loss of friction. Therefore, inspecting these seals for leakage is a mandatory step during every service interval of the FAW Russian Front Right Brake.

Finally, the FAW Russian Front Right Brake relies on the integrity of its fasteners. The Hexagon Head Bolt (Part No. CQ1501016) and corresponding Spring Washer (Part No. Q40310) must be torqued to spec. Loose bolts on the dust shield or anchor pins can lead to rattling and eventual fatigue failure. By strictly adhering to the parts list and maintenance procedures for the FAW Russian Front Right Brake, operators maximize uptime and safety.

Conclusion: The Anchor of Safety

The FAW Russian Front Right Brake is a complex assembly where 53 distinct components work in unison to provide safety and control. From the friction-generating Front Brake Shoe Lining to the force-multiplying Front Right Brake Camshaft, every part is tailored for the rigors of the Russian environment. The robust Front Right Brake Bracket provides the necessary rigidity, while the advanced sealing system ensures long service intervals.

For fleet managers, the message is clear: there is no substitute for genuine parts when servicing the FAW Russian Front Right Brake. Using authentic Return Spring units and correct specification linings ensures that the braking performance remains balanced and predictable. By maintaining the FAW Russian Front Right Brake according to factory standards, operators protect their drivers, their cargo, and their bottom line against the unpredictable challenges of the road.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.