FAW Russian Front Shock Upper-Mount: Securing 3 Vital Structural Nodes for Damping Precision

The FAW Russian Front Shock Upper-Mount assembly is the definitive structural interface between the hydraulic damping system and the chassis frame of the CA3250P66K24L1TE5Z dump truck. Unlike the lower mount which moves with the axle, this upper bracket must remain absolutely rigid, absorbing the violent kinetic energy converted by the shock absorber during rebound and compression strokes. Engineered with “55R” specification metallurgy, the FAW Russian Front Shock Upper-Mount is designed to resist fatigue cracking even when subjected to the high-frequency vibrations of frozen Siberian haul roads. This guide details the bracket’s architecture and the high-tensile fastening logic that keeps it secure.

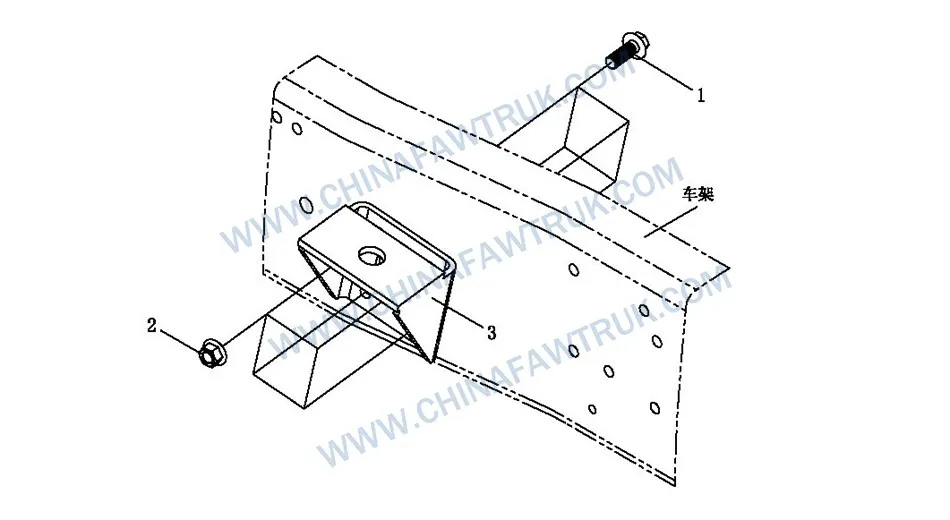

FAW Russian Front Shock Upper-Mount

Bracket Metallurgy and Structural Design

The core of this assembly is the Upper Bracket Assembly – Front Shock Absorber (Part No. 2905415-55R). This component is not a simple stamped piece of sheet metal; it is a heavy-duty fabrication or casting designed to handle multi-directional stress. In the FAW Russian Front Shock Upper-Mount application, the bracket must withstand the vertical thrust of the shock absorber pushing upwards during compression (bump) and the downward pulling force during rebound (droop). The “55R” suffix indicates a specific low-temperature steel alloy or heat treatment process. This is crucial for the Russian market because standard structural steel can become brittle at -50°C. The FAW Russian Front Shock Upper-Mount bracket maintains its ductility, allowing it to flex microscopically under peak loads rather than snapping.

The geometry of the Upper Bracket Assembly – Front Shock Absorber (Part No. 2905415-55R) features a cantilevered design. It bolts to the vertical web of the chassis frame rail and extends outward to align with the shock absorber eye. To prevent flexing, the bracket incorporates stiffening ribs and gussets. These structural elements distribute the point load from the shock mount over a wide footprint on the frame rail. If the FAW Russian Front Shock Upper-Mount were to flex, it would lead to metal fatigue in the chassis rail itself, potentially causing cracks in the main frame. Therefore, the rigidity of this component is a primary factor in the overall durability of the vehicle’s skeleton.

The mounting ear of the FAW Russian Front Shock Upper-Mount is precision-drilled to accept the upper shock bolt. The alignment of this hole is critical. It must be perfectly parallel to the lower shock mount on the axle. Any angular misalignment would force the shock absorber piston to bind inside its cylinder, destroying the seals and valving. FAW’s manufacturing tolerances for the Upper Bracket Assembly – Front Shock Absorber ensure that the shock operates in a true vertical plane, maximizing the lifespan of the damping unit.

Surface protection is another critical aspect of the FAW Russian Front Shock Upper-Mount. Located high in the wheel well, it is exposed to a constant spray of road salts, gravel, and ice. The bracket undergoes an electrophoretic coating (E-coat) process followed by a robust chassis paint application. This multi-layer defense prevents corrosion from compromising the structural integrity of the Upper Bracket Assembly – Front Shock Absorber. Fleet managers should regularly inspect this coating; any chips or rust spots should be treated immediately to prevent the onset of structural decay in this critical safety component.

High-Shear Fastening Architecture

The connection between the FAW Russian Front Shock Upper-Mount and the chassis is secured by four Hexagon Head Flange Bolts (Part No. Q1851445T). These are not standard bolts; the “1445T” designation implies a specific length (45mm) and a high-tensile strength rating, typically Grade 10.9. These bolts act as the shear pins for the assembly. Every time the suspension cycles, the damping force tries to shear these bolts off the frame. The high-grade steel used in the FAW Russian Front Shock Upper-Mount fasteners ensures they have the shear strength to resist these forces indefinitely.

The flange head design of the Hexagon Head Flange Bolt (Part No. Q1851445T) is a deliberate engineering choice. By integrating the washer into the bolt head, the clamping force is distributed over a larger area of the bracket surface. This prevents the bolt head from embedding into the Upper Bracket Assembly – Front Shock Absorber, which would lead to a loss of torque tension. In the high-vibration environment of a diesel truck, maintaining bolt preload is essential. If the bolts loosen, the bracket will begin to “fret” against the frame, elongating the mounting holes and ruining both components.

Corrosion resistance for the fasteners is paramount in the Russian operational theater. The Hexagon Head Flange Bolt (Part No. Q1851445T) features a Dacromet or zinc-flake coating. This sacrificial layer protects the threads from seizing due to rust. When a mechanic needs to replace a shock bracket after five years of service in Siberia, this coating ensures that the bolts can be removed without snapping, significantly reducing maintenance downtime. The FAW Russian Front Shock Upper-Mount system is designed for serviceability as much as for durability.

The bolt pattern on the FAW Russian Front Shock Upper-Mount is arranged to maximize stability. By spacing the four bolts in a wide rectangular or trapezoidal pattern, the design resists the rotational torque applied to the bracket. This leverage ensures that the bracket cannot twist on the frame rail, maintaining the precise alignment required for the shock absorber. The engineering logic behind the FAW Russian Front Shock Upper-Mount fastening system prioritizes absolute rigidity in all planes of motion.

Nut Technology and Locking Logic

Securing the flange bolts are four Hexagon Flange Nuts (Part No. CQ39714). These nuts are the final line of defense against vibration-induced loosening. The FAW Russian Front Shock Upper-Mount utilizes a locking nut design, likely featuring a distorted thread form or a serrated bearing face. This prevailing torque feature ensures that even if the clamping load is momentarily reduced due to thermal contraction in the -50°C cold, the nut will not back off. The reliability of the FAW Russian Front Shock Upper-Mount depends entirely on these four nuts remaining tight.

The Hexagon Flange Nut (Part No. CQ39714) works in tandem with the flange bolt to create a “hard” joint. Because there are no soft gaskets or compressible washers in the stack, the torque applied to the nut translates directly into clamping force. This metal-on-metal contact is essential for transferring the shock loads directly to the chassis frame. Any compliance in the fastening system of the FAW Russian Front Shock Upper-Mount would lead to a dampening of the shock’s effectiveness and accelerated wear of the mounting points.

It is a critical maintenance protocol to treat the Hexagon Flange Nut (Part No. CQ39714) as a single-use item in critical applications. While they can physically be reused, the locking feature degrades after the first installation. Given the low cost of the nut versus the high cost of a suspension failure, FAW recommends installing new nuts whenever the Upper Bracket Assembly – Front Shock Absorber is removed. This ensures that the locking retention meets factory specifications every time.

Visual inspection of the FAW Russian Front Shock Upper-Mount fasteners should be part of the daily pre-start check. Drivers and mechanics should look for “rust trails” running down from the nut or bolt head. This fine red dust is a tell-tale sign of movement in the joint. If detected, immediate re-torquing is required to save the bracket. The FAW Russian Front Shock Upper-Mount is designed to be robust, but it requires vigilant maintenance to perform in the harsh Russian environment.

Impact of Failure and Maintenance Strategy

Failure of the FAW Russian Front Shock Upper-Mount leads to immediate and severe consequences. If the bracket cracks or the bolts shear, the top of the shock absorber becomes detached. This allows the shock to flail around inside the wheel well, potentially damaging the brake lines, air bags, or tires. Furthermore, without the damping provided by the shock, the leaf spring will oscillate uncontrollably, leading to a loss of steering control on uneven surfaces. The FAW Russian Front Shock Upper-Mount is therefore a safety-critical component that demands zero tolerance for wear or damage.

In the event of a damaged bracket, welding is generally discouraged. The heat from welding can alter the temper of the “55R” alloy steel, creating brittle zones that will fracture again under load. Replacement with a genuine Upper Bracket Assembly – Front Shock Absorber (Part No. 2905415-55R) is the only approved repair method. This ensures that the metallurgy and geometric precision of the repair match the original engineering intent of the FAW Russian Front Shock Upper-Mount.

Installation of the FAW Russian Front Shock Upper-Mount must follow a specific sequence. The bracket should be bolted to the frame first, and the bolts torqued to specification. Only then should the shock absorber be attached. Attempting to force the bracket into place with the shock already attached can preload the bushing, leading to premature failure. Following the correct procedure ensures that the FAW Russian Front Shock Upper-Mount sits stress-free in its static position, ready to absorb the dynamic loads of the road.

By adhering to these maintenance guidelines and utilizing the correct “55R” specification parts, fleet operators can ensure that their CA3250P66K24L1TE5Z trucks remain operational. The FAW Russian Front Shock Upper-Mount is a small assembly with a massive responsibility, acting as the anchor for the vehicle’s ride control system in the most unforgiving terrain on earth.

Component Breakdown: Front Shock Absorber Upper Bracket Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 | CQ39714 | Hexagon Flange Nut | 4 |

| 2 | Q1851445T | Hexagon Head Flange Bolt | 4 |

| 3 | 2905415-55R | Upper Bracket Assembly – Front Shock Absorber | 1 |

Conclusion: The Foundation of Control

The FAW Russian Front Shock Upper-Mount is more than a simple mounting point; it is a critical node in the suspension architecture that dictates the vehicle’s handling stability. Its robust design, featuring “55R” steel and high-shear flange bolts, ensures that it can withstand the extreme rigors of arctic mining operations. Every component, from the Upper Bracket Assembly – Front Shock Absorber (Part No. 2905415-55R) to the locking Hexagon Flange Nut (Part No. CQ39714), plays a vital role in keeping the truck safe and controllable.

Fleet managers must prioritize the inspection and maintenance of this assembly. Ensuring that the FAW Russian Front Shock Upper-Mount remains securely fastened and free of corrosion damage is the key to preventing costly suspension failures and maximizing the uptime of the CA3250P66K24L1TE5Z fleet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.