Montaje superior del amortiguador delantero ruso FAW: Asegurar 3 Nodos estructurales vitales para la precisión de la amortiguación

El Montaje superior del amortiguador delantero ruso FAW El conjunto es la interfaz estructural definitiva entre el sistema de amortiguación hidráulica y el bastidor del chasis del camión volquete CA3250P66K24L1TE5Z.. A diferencia del soporte inferior que se mueve con el eje., este soporte superior debe permanecer absolutamente rígido, Absorber la violenta energía cinética convertida por el amortiguador durante los golpes de rebote y compresión.. Diseñado con “55R” especificación metalurgia, el Montaje superior del amortiguador delantero ruso FAW está diseñado para resistir el agrietamiento por fatiga incluso cuando se lo somete a las vibraciones de alta frecuencia de los caminos de transporte congelados de Siberia.. Esta guía detalla la arquitectura del soporte y la lógica de sujeción de alta resistencia que lo mantiene seguro..

Montaje superior del amortiguador delantero ruso FAW

Metalurgia de soportes y diseño estructural.

El núcleo de esta asamblea es el Conjunto de soporte superior – Amortiguador delantero (Número de pieza. 2905415-55R). Este componente no es una simple pieza de chapa estampada.; Es una fabricación o fundición de alta resistencia diseñada para soportar tensiones multidireccionales.. En el Montaje superior del amortiguador delantero ruso FAW solicitud, El soporte debe soportar el empuje vertical del amortiguador que empuja hacia arriba durante la compresión. (bulto) y la fuerza de tracción hacia abajo durante el rebote (inclinarse). El “55R” El sufijo indica una aleación de acero de baja temperatura específica o un proceso de tratamiento térmico.. Esto es crucial para el mercado ruso porque el acero estructural estándar puede volverse quebradizo a -50°C.. El Montaje superior del amortiguador delantero ruso FAW El soporte mantiene su ductilidad., permitiéndole flexionarse microscópicamente bajo cargas máximas en lugar de romperse.

La geometría del Conjunto de soporte superior – Amortiguador delantero (Número de pieza. 2905415-55R) presenta un diseño en voladizo. Se atornilla a la red vertical del riel del bastidor del chasis y se extiende hacia afuera para alinearse con el ojo del amortiguador.. Para evitar la flexión, el soporte incorpora nervaduras de refuerzo y refuerzos. Estos elementos estructurales distribuyen la carga puntual del soporte amortiguador sobre una amplia huella en el riel del marco.. si el Montaje superior del amortiguador delantero ruso FAW fueran a flexionar, provocaría fatiga del metal en el propio riel del chasis, potencialmente causando grietas en el marco principal. Por lo tanto, La rigidez de este componente es un factor principal en la durabilidad general del esqueleto del vehículo..

La oreja de montaje del Montaje superior del amortiguador delantero ruso FAW Está perforado con precisión para aceptar el perno de choque superior.. La alineación de este agujero es crítica.. Debe quedar perfectamente paralelo al soporte inferior del amortiguador del eje.. Cualquier desalineación angular obligaría al pistón del amortiguador a atascarse dentro de su cilindro., destruyendo los sellos y válvulas. Las tolerancias de fabricación de FAW para el Conjunto de soporte superior – Amortiguador delantero Asegúrese de que el amortiguador funcione en un verdadero plano vertical., Maximizar la vida útil de la unidad de amortiguación..

La protección de superficies es otro aspecto crítico de la Montaje superior del amortiguador delantero ruso FAW. Ubicado en lo alto del hueco de la rueda, está expuesto a un rocío constante de sales de carretera, grava, y hielo. El bracket se somete a un recubrimiento electroforético. (abrigo electrónico) Proceso seguido de una robusta aplicación de pintura al chasis.. Esta defensa multicapa evita que la corrosión comprometa la integridad estructural del Conjunto de soporte superior – Amortiguador delantero. Los gestores de flotas deberían inspeccionar periódicamente este revestimiento.; cualquier astilla o punto de óxido debe tratarse inmediatamente para evitar la aparición de deterioro estructural en este componente crítico de seguridad..

Arquitectura de fijación de alto corte

La conexión entre el Montaje superior del amortiguador delantero ruso FAW y el chasis está asegurado por cuatro Pernos de brida de cabeza hexagonal (Número de pieza. Q1851445T). Estos no son tornillos estándar.; el “1445t” la designación implica una longitud específica (45milímetros) y una calificación de alta resistencia a la tracción, típicamente grado 10.9. Estos pernos actúan como pasadores de seguridad para el ensamblaje.. Cada vez que la suspensión realiza un ciclo, la fuerza de amortiguación intenta arrancar estos pernos del marco. El acero de alta calidad utilizado en la Montaje superior del amortiguador delantero ruso FAW Los sujetadores garantizan que tengan la resistencia al corte para resistir estas fuerzas indefinidamente..

El diseño de cabeza de brida del Perno de brida de cabeza hexagonal (Número de pieza. Q1851445T) es una elección de ingeniería deliberada. Integrando la arandela en la cabeza del perno., la fuerza de sujeción se distribuye sobre un área más grande de la superficie del soporte. Esto evita que la cabeza del perno se incruste en el Conjunto de soporte superior – Amortiguador delantero, lo que conduciría a una pérdida de tensión de torsión. En el entorno de alta vibración de un camión diésel, mantener la precarga del perno es esencial. Si los tornillos se aflojan, el soporte comenzará a “traste” contra el marco, alargando los orificios de montaje y arruinando ambos componentes.

La resistencia a la corrosión de los elementos de fijación es primordial en el teatro de operaciones ruso. El Perno de brida de cabeza hexagonal (Número de pieza. Q1851445T) Cuenta con un revestimiento de Dacromet o escamas de zinc.. Esta capa de sacrificio protege las roscas contra el agarrotamiento debido al óxido.. Cuando un mecánico necesita reemplazar un soporte de amortiguador después de cinco años de servicio en Siberia, este recubrimiento garantiza que los pernos se puedan quitar sin romperse, reduciendo significativamente el tiempo de inactividad por mantenimiento. El Montaje superior del amortiguador delantero ruso FAW El sistema está diseñado tanto para ofrecer facilidad de servicio como durabilidad..

El patrón de pernos en el Montaje superior del amortiguador delantero ruso FAW está dispuesto para maximizar la estabilidad. Espaciando los cuatro pernos en un patrón ancho rectangular o trapezoidal, el diseño resiste el par de rotación aplicado al soporte. Este apalancamiento asegura que el soporte no pueda girar en el riel del marco., manteniendo la alineación precisa requerida para el amortiguador. La lógica de ingeniería detrás de la Montaje superior del amortiguador delantero ruso FAW El sistema de fijación prioriza la rigidez absoluta en todos los planos de movimiento..

Tecnología de tuercas y lógica de bloqueo

Para asegurar los pernos de la brida hay cuatro Tuercas con brida hexagonal (Número de pieza. CQ39714). Estas tuercas son la última línea de defensa contra el aflojamiento inducido por vibraciones.. El Montaje superior del amortiguador delantero ruso FAW utiliza un diseño de tuerca de bloqueo, Probablemente presenta una forma de rosca distorsionada o una cara de rodamiento dentada.. Esta característica de par predominante garantiza que incluso si la carga de sujeción se reduce momentáneamente debido a la contracción térmica en temperaturas frías de -50 °C, la tuerca no retrocederá. La confiabilidad del Montaje superior del amortiguador delantero ruso FAW depende enteramente de que estas cuatro tuercas permanezcan apretadas.

El Tuerca con brida hexagonal (Número de pieza. CQ39714) Funciona en conjunto con el perno de brida para crear un “duro” articulación. Porque no hay juntas blandas ni arandelas comprimibles en la pila, El par aplicado a la tuerca se traduce directamente en fuerza de sujeción.. Este contacto metal sobre metal es esencial para transferir las cargas de impacto directamente al bastidor del chasis.. Cualquier cumplimiento en el sistema de fijación del Montaje superior del amortiguador delantero ruso FAW provocaría una disminución de la eficacia del amortiguador y un desgaste acelerado de los puntos de montaje.

Es un protocolo de mantenimiento crítico para tratar el Tuerca con brida hexagonal (Número de pieza. CQ39714) como artículo de un solo uso en aplicaciones críticas. Si bien se pueden reutilizar físicamente, La función de bloqueo se degrada después de la primera instalación.. Dado el bajo costo de la tuerca versus el alto costo de una falla en la suspensión, FAW recomienda instalar tuercas nuevas siempre que Conjunto de soporte superior – Amortiguador delantero se elimina. Esto garantiza que la retención de bloqueo cumpla con las especificaciones de fábrica en todo momento..

Inspección visual del Montaje superior del amortiguador delantero ruso FAW Los sujetadores deben ser parte de la revisión diaria previa al arranque.. Los conductores y mecánicos deben buscar “senderos de óxido” corriendo hacia abajo desde la cabeza de la tuerca o del perno. Este fino polvo rojo es un signo revelador de movimiento en la articulación.. Si se detecta, Se requiere un nuevo torque inmediato para salvar el soporte.. El Montaje superior del amortiguador delantero ruso FAW está diseñado para ser robusto, pero requiere un mantenimiento cuidadoso para funcionar en el duro entorno ruso..

Impacto de la falla y estrategia de mantenimiento

fracaso de la Montaje superior del amortiguador delantero ruso FAW conduce a consecuencias inmediatas y graves. Si el soporte se agrieta o los pernos se cortan, la parte superior del amortiguador se desprende. Esto permite que el amortiguador se mueva dentro del hueco de la rueda., potencialmente dañar las líneas de freno, bolsas de aire, o llantas. Además, sin la amortiguación proporcionada por el choque, la ballesta oscilará incontrolablemente, lo que provoca una pérdida de control de la dirección en superficies irregulares. El Montaje superior del amortiguador delantero ruso FAW Por lo tanto, es un componente crítico para la seguridad que exige tolerancia cero ante el desgaste o los daños..

En caso de soporte dañado, En general, se desaconseja la soldadura.. El calor de la soldadura puede alterar el temperamento de la “55R” acero aleado, creando zonas frágiles que se fracturarán nuevamente bajo carga. Reemplazo con uno genuino Conjunto de soporte superior – Amortiguador delantero (Número de pieza. 2905415-55R) es el único método de reparación aprobado. Esto garantiza que la metalurgia y la precisión geométrica de la reparación coincidan con la intención de ingeniería original de la reparación. Montaje superior del amortiguador delantero ruso FAW.

Instalación del Montaje superior del amortiguador delantero ruso FAW debe seguir una secuencia específica. El soporte debe atornillarse primero al marco., y los pernos apretados según las especificaciones. Sólo entonces se debe colocar el amortiguador.. Intentar forzar el soporte en su lugar con el amortiguador ya colocado puede precargar el casquillo., conduciendo a un fracaso prematuro. Seguir el procedimiento correcto garantiza que el Montaje superior del amortiguador delantero ruso FAW se sienta sin estrés en su posición estática, Listo para absorber las cargas dinámicas de la carretera..

Al seguir estas pautas de mantenimiento y utilizar las herramientas correctas “55R” piezas de especificación, Los operadores de flotas pueden garantizar que sus camiones CA3250P66K24L1TE5Z permanezcan operativos.. El Montaje superior del amortiguador delantero ruso FAW Es una pequeña asamblea con una enorme responsabilidad., Actuando como ancla para el sistema de control de conducción del vehículo en el terreno más implacable del mundo..

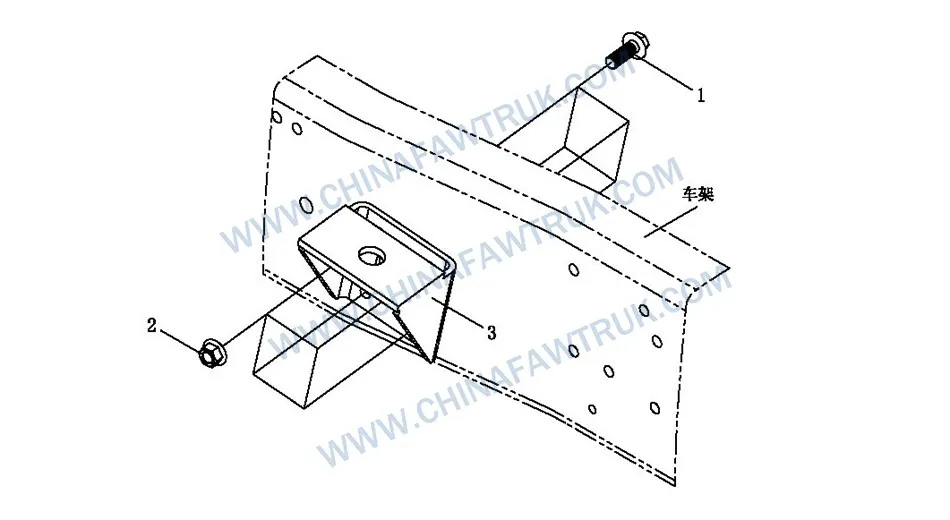

Desglose de componentes: Conjunto lógico del soporte superior del amortiguador delantero

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | CQ39714 | Tuerca con brida hexagonal | 4 |

| 2 | Q1851445T | Perno de brida de cabeza hexagonal | 4 |

| 3 | 2905415-55R | Conjunto de soporte superior – Amortiguador delantero | 1 |

Conclusión: La base del control

El Montaje superior del amortiguador delantero ruso FAW es más que un simple punto de montaje; Es un nodo crítico en la arquitectura de la suspensión que dicta la estabilidad de manejo del vehículo.. Su diseño robusto, presentando “55R” pernos de brida de acero y de alto corte, Garantiza que puede soportar los rigores extremos de las operaciones mineras en el Ártico.. Cada componente, desde Conjunto de soporte superior – Amortiguador delantero (Número de pieza. 2905415-55R) al bloqueo Tuerca con brida hexagonal (Número de pieza. CQ39714), Desempeña un papel vital para mantener el camión seguro y controlable..

Los gestores de flotas deberán priorizar la inspección y mantenimiento de este conjunto. Asegurando que el Montaje superior del amortiguador delantero ruso FAW permanece firmemente sujeto y libre de daños por corrosión es la clave para evitar costosas fallas en la suspensión y maximizar el tiempo de actividad de la flota CA3250P66K24L1TE5Z.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.