FAW Russian Dual-Axis Assembly: Mastering 13 Critical Components for Precision Torque Management

The FAW Russian Dual-Axis Assembly, technically known as the transmission main shaft, is the torque-delivery backbone of the CA3250P66K24L1TE5Z dump truck. Situated at the core of the gearbox, this assembly manages the complex interplay of sliding gears and locking keys to define vehicle speed and power. This guide dissects the 13 essential components ensuring seamless shifting in Arctic conditions.

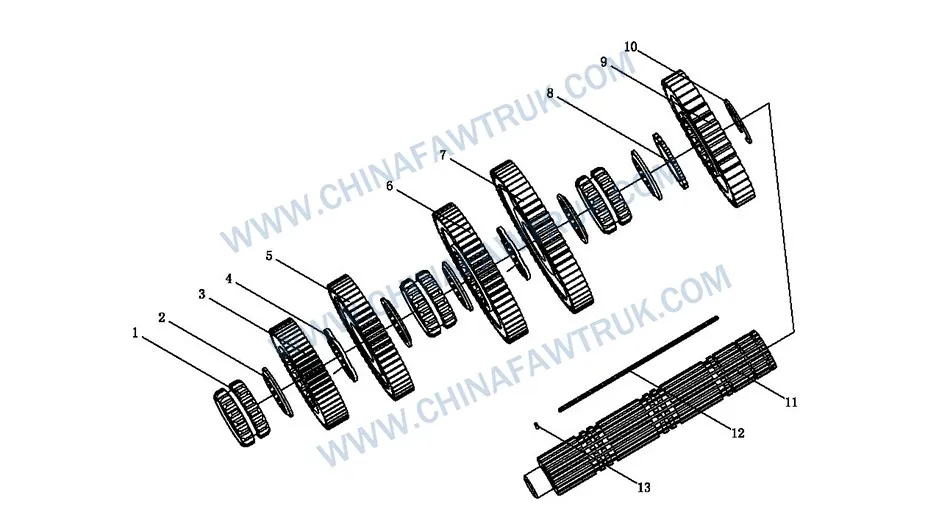

FAW Russian Dual-Axis Assembly

Core Architecture: The Splined Spine

The foundation of the FAW Russian Dual-Axis Assembly is the 2nd Shaft (Part No. 1701301-A8P). This massive steel component acts as the output carrier for the transmission. Unlike the input shaft which brings power in, the FAW Russian Dual-Axis Assembly shaft determines how that power is modulated before reaching the differential. It must resist extreme torsional twisting forces, especially when a fully loaded dump truck attempts to move on a steep, icy incline. The shaft is machined from high-strength alloy steel, carburized to create a hard, wear-resistant surface while maintaining a tough, ductile core to prevent snapping under shock loads.

A unique feature of the FAW Russian Dual-Axis Assembly is its locking mechanism, the Three-sided Key (Part No. 1701332-A7G). Unlike traditional single-key designs, this trilateral key distributes the torque load across three distinct contact points. This design significantly reduces the shear stress on any single point of the shaft. In the context of the FAW Russian Dual-Axis Assembly, this is critical for longevity. The constant engagement and disengagement of gears create cyclic loading that would quickly wallow out a standard keyway. The three-sided key ensures that the fixed components remain rigidly locked to the shaft for the life of the vehicle.

Securing this key is the Snap Ring – Three-sided Key (Part No. 1701333-A7G). This retaining ring prevents the key from migrating axially under vibration. In the high-vibration environment of a diesel powertrain, unsecured components will “walk” out of position. The FAW Russian Dual-Axis Assembly utilizes this snap ring as a positive stop, ensuring that the torque transfer mechanism remains intact even when the transmission oil is cold and viscous, exerting drag on the internal components.

Gear Logic: Optimized Ratios for Heavy Hauling

The FAW Russian Dual-Axis Assembly carries the entire suite of forward and reverse gears. This includes the 1st Gear – 2nd Shaft (Part No. 1701317-A7G), 2nd Gear – 2nd Shaft (Part No. 1701321-A7G), 3rd Gear – 2nd Shaft (Part No. 1701322-A7G), and 5th Gear – 2nd Shaft (Part No. 1701323-A1K). Each of these gears floats on the main shaft on needle bearings or bushings. They are in constant mesh with the countershaft but do not transmit power until locked to the shaft by the sliding sleeve. The precision of the gear bore finishing in the FAW Russian Dual-Axis Assembly is vital.

In the Russian Arctic, transmission fluid thickens at -40°C. If the clearance between the floating gear and the shaft is too tight, the viscous drag will cause the vehicle to creep even when in neutral. If too loose, the gears will rattle and whine. The FAW Russian Dual-Axis Assembly features optimized clearances that balance cold-weather free-wheeling with hot-weather stability. The gears themselves are helical-cut to maximize tooth contact area, spreading the load and reducing noise. This geometry is essential for the FAW Russian Dual-Axis Assembly to handle the massive torque multiplication required for off-road dumping.

The assembly also houses the Reverse Gear – 2nd Shaft (Part No. 1701311-A7G). Reverse gear often sees the highest torque loads when backing a loaded truck up a grade. The FAW Russian Dual-Axis Assembly ensures this gear is robustly supported. It is positioned by the Locating Ring – Reverse Gear (Part No. 1701312-A7G), which prevents axial thrust from disengaging the gear under load. This positive retention is a safety feature, ensuring the truck does not pop out of gear during critical maneuvers.

Engagement Logic: The Sliding Sleeve

The actual act of changing gears is facilitated by the Sliding Gear Sleeve (Part No. 1701316-A8P). In the FAW Russian Dual-Axis Assembly, this component acts as the bridge. Splined to the main shaft hub, it slides axially to engage the dog teeth of the selected floating gear. The durability of the internal splines on this sleeve is the defining factor in shift quality. Burred or worn splines lead to hard shifting or “gear block,” where the driver cannot engage a gear.

The FAW Russian Dual-Axis Assembly utilizes a sliding sleeve manufactured from heat-treated steel with a specific chamfer profile on the leading edges of the teeth. This profile helps to guide the sleeve onto the gear, smoothing the transition even if the speeds are not perfectly matched. In the context of a non-synchronized or partially synchronized heavy truck transmission, this design feature reduces driver fatigue and prevents gear grinding. The sleeve must also resist the wear of the shift fork pads, ensuring that the FAW Russian Dual-Axis Assembly maintains precise shift detents over time.

The movement of the sleeve is constrained by the Elastic Cylindrical Pin (Part No. Q5280310) and associated hardware. These small components play a massive role in the FAW Russian Dual-Axis Assembly. They ensure that the shifting mechanism remains aligned and that the sleeve does not over-travel, which could lead to simultaneous engagement of two gears—a catastrophic failure mode that locks the transmission and can shatter the case.

Spacing Logic: Limit Washers

Maintaining the correct spacing between the spinning gears is the function of the Limit Washer – Gear (Part No. 1701327-A7G) and Inter-shaft Limit Washer (Part No. 1701318-A7G). The FAW Russian Dual-Axis Assembly employs five of the former and two of the latter. These are not simple spacers; they are precision-ground bearing surfaces. They absorb the axial thrust loads generated by the helical gears and prevent the gears from rubbing against each other or the housing.

In the FAW Russian Dual-Axis Assembly, the material of these washers is typically a hardened steel or a bronze-alloy composite. They must withstand high surface speeds and significant compressive loads. If a washer wears thin, the axial end-play of the gear increases. Excessive end-play allows the gear to tilt slightly on the shaft, leading to poor tooth contact patterns, increased noise, and eventually, gear tooth breakage.

The strategic placement of these washers within the FAW Russian Dual-Axis Assembly also facilitates oil flow. They are often designed with oil grooves or slots that allow lubricant to penetrate between the washer and the gear face. This hydrodynamic lubrication film prevents galling and seizure, particularly during high-speed highway driving when the relative speeds between the shaft and the floating gears are at their maximum. This attention to tribology ensures the FAW Russian Dual-Axis Assembly survives the harshest operating conditions.

Component Breakdown: 105. Dual-Axis Component Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1701316-A8P |

Sliding Gear Sleeve |

1 |

| 2 |

1701327-A7G |

Limit Washer – Gear |

5 |

| 3 |

1701323-A1K |

5th Gear – 2nd Shaft |

1 |

| 4 |

1701318-A7G |

Inter-shaft Limit Washer |

2 |

| 5 |

1701322-A7G |

3rd Gear – 2nd Shaft |

1 |

| 6 |

1701321-A7G |

2nd Gear – 2nd Shaft |

1 |

| 7 |

1701317-A7G |

1st Gear – 2nd Shaft |

1 |

| 8 |

1701312-A7G |

Locating Ring – Reverse Gear |

1 |

| 9 |

1701311-A7G |

Reverse Gear – 2nd Shaft |

1 |

| 10 |

1701333-A7G |

Snap Ring – Three-sided Key |

1 |

| 11 | 1701301-A8P |

2nd Shaft (Main Shaft) |

1 |

| 12 |

1701332-A7G |

Three-sided Key |

1 |

| 13 | Q5280310 |

Elastic Cylindrical Pin |

1 |

Conclusion: The Core of Transmission

The FAW Russian Dual-Axis Assembly is the central nervous system of the truck’s power delivery. It coordinates the complex mechanical ballet of gears, keys, and sliding sleeves to convert raw engine torque into usable wheel speed. Its design reflects a deep engineering commitment to reliability in extreme cold, from the selection of steel alloys to the precision of the clearance tolerances.

For transmission technicians, rebuilding this assembly requires strict adherence to the parts list. Substituting a generic key or a washer of incorrect thickness will disrupt the delicate internal balance of the FAW Russian Dual-Axis Assembly, leading to rapid failure. By utilizing genuine FAW components, operators ensure that their transmission remains a robust, efficient link in the powertrain chain, capable of conquering the toughest jobs on the planet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.