FAW Russian Engine Mounting Logic: Deconstructing 18 Components for Arctic Vibration Control

The FAW Russian Engine Mounting Logic is the structural interface between the high-torque diesel heart and the rigid chassis of the CA3250P66K24L1TE5Z dump truck. In the extreme cold of the Russian Federation, this system does more than simply hold the engine in place; it acts as a complex harmonic damper. By isolating the cabin and frame from the violent combustion forces of the engine, the FAW Russian Engine Mounting Logic protects sensitive electronics and reduces driver fatigue. This guide dissects the assembly into its critical brackets, cushions, and fasteners, providing a roadmap for maintenance in sub-zero conditions.

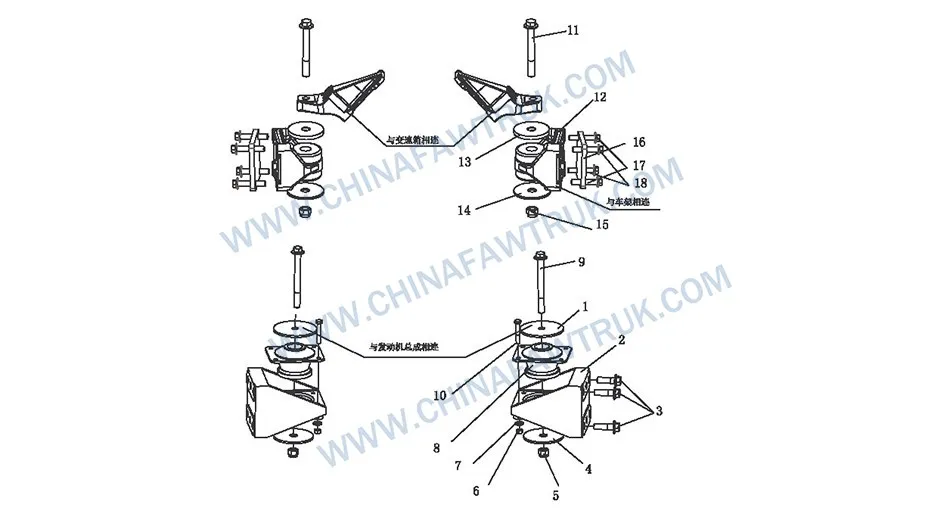

FAW Russian Engine Mounting Logic

Front Architecture: Managing Vertical Load

The forward section of the FAW Russian Engine Mounting Logic is engineered to handle the primary vertical mass of the engine block. At the core of this subsystem is the Engine Front Suspension Bracket (Part No. 1001037-76A). This heavy-duty casting acts as the anchor point, bolted securely to the engine structure. It must withstand not only the static weight of the engine but also the dynamic G-forces experienced when the truck traverses rough mining roads or frozen ruts. The metallurgy of this bracket is specifically chosen to resist brittle fracture at temperatures as low as -50°C, a common failure point for inferior metals in the Russian Arctic.

Working in tandem with the bracket is the Engine Front Suspension Cushion Assembly (Part No. 1001025-76A). This is the damping element, typically comprised of a sophisticated rubber compound bonded to steel plates. In the FAW Russian Engine Mounting Logic, the rubber formulation is critical. Standard natural rubber turns glass-hard in extreme cold, losing its ability to absorb vibration. This specialized cushion retains flexibility, ensuring that the high-frequency vibrations from the diesel combustion cycle are absorbed before they can propagate into the chassis frames. The integrity of this cushion is protected by the Engine Front Suspension Top Cover Assembly (Part No. 1001030-76A), which shields the rubber from oil drips and road debris that could degrade its chemical structure.

To ensure the assembly remains coherent under heavy load, the Lower Cushion Plate – Engine Front Suspension (Part No. 1001028-76A) provides a rigid base for the mounting stack. This plate distributes the compressive loads evenly across the chassis mounting point, preventing localized stress fractures. The interaction between the top cover, the cushion assembly, and the lower plate creates a “sandwich” structure within the FAW Russian Engine Mounting Logic that effectively decouples the engine’s movement from the truck’s frame, providing a stable platform for power generation even on the most uneven terrain.

Rear Architecture: Torque Reaction and Stability

While the front mounts handle weight, the rear section of the FAW Russian Engine Mounting Logic is primarily tasked with managing torque reaction. Every time the engine accelerates, the block attempts to rotate in the opposite direction of the crankshaft. The Rear Suspension Bracket Cushion Assembly (Part No. 1001065-50V) is positioned to counteract this twisting force. Unlike the front mounts, these rear cushions often feature a different durometer (hardness) rubber to stiffer resistance against lateral movement while still permitting vertical damping. This balance is crucial for maintaining driveline alignment between the engine and the transmission.

Structural integrity at the rear is reinforced by the Upper Cushion Plate – Engine Rear Suspension (Part No. 1001063-483) and the Bottom Plate – Rear Suspension (Part No. 1001079-263). These steel plates encase the rear cushion, acting as limiters. In the event of a severe shock—such as hitting a deep pothole at speed—these plates prevent the rubber mount from over-extending or tearing. The FAW Russian Engine Mounting Logic relies on these plates to act as a fail-safe mechanism, keeping the engine captive even if the rubber element were to degrade significantly.

Additionally, the system employs the Rear Suspension Cushion Plate (Part No. 1001064-64W) to fine-tune the assembly’s height and preload. Proper alignment is non-negotiable in the FAW Russian Engine Mounting Logic. If the engine is tilted even slightly due to a collapsed rear mount, it puts immense strain on the universal joints of the driveshaft and the transmission input shaft bearing. Regular inspection of these rear components ensures that the entire powertrain operates on its designed geometric axis, preventing secondary failures in the transmission or differential.

Fastener Technology: Securing the Load

The robust castings and rubber cushions of the FAW Russian Engine Mounting Logic are rendered useless without high-grade fasteners to hold them together. The assembly utilizes specific Hexagon Head Flange Bolts (Part No. Q1851650TS and Q18516160TS) for critical connections. The flange head design is superior to standard bolt-and-washer combinations in high-vibration environments. The flange acts as an integrated washer, distributing the clamping load over a wider surface area and preventing the bolt head from embedding into the softer bracket material. This ensures that the torque preload remains consistent over time.

To prevent loosening, the system employs the Type 1 Non-metallic Insert Hexagon Lock Nut (Part No. Q32916T and Q32918T). These nuts feature a nylon ring embedded in the top threads. When the bolt is driven through, the nylon deforms, creating a high-friction interference fit that resists the constant vibrational energy of the diesel engine. In the cold of Russia, where metal contracts and gaps can open, these nylon inserts provide a critical layer of security within the FAW Russian Engine Mounting Logic, ensuring that the nuts do not back off.

Furthermore, the assembly includes specialized washers like the Conical Spring Washer (Part No. CQ41910). Unlike a flat washer, a conical washer acts as a spring, maintaining tension on the bolt assembly even if the components undergo thermal contraction or slight settling. This is particularly important for the FAW Russian Engine Mounting Logic which operates across a vast temperature delta. From the heat of the engine bay to the freezing ambient air, these fasteners must maintain their grip to ensure the safety and stability of the entire powertrain.

Component Breakdown List

The table below provides the comprehensive parts list for the FAW Russian Engine Mounting Logic. When performing maintenance or overhauls, strictly adhering to these part numbers ensures compatibility with the cold-weather specifications of the CA3250P66K24L1TE5Z dump truck.

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1001030-76A |

Engine Front Suspension Top Cover Assembly |

2 |

| 2 |

1001037-76A |

Engine Front Suspension Bracket |

2 |

| 3 |

Q1851650TS |

Hexagon Head Flange Bolt |

12 |

| 4 |

1001028-76A |

Lower Cushion Plate – Engine Front Suspension |

2 |

| 5 |

Q32916T |

Type 1 Non-metallic Insert Hexagon Lock Nut |

2 |

| 6 |

CQ34010T |

Hexagon Nut |

8 |

| 7 |

CQ41910 |

Conical Spring Washer |

8 |

| 8 |

1001025-76A |

Engine Front Suspension Cushion Assembly |

2 |

| 9 |

Q18516160TS |

Hexagon Head Flange Bolt |

2 |

| 10 |

CQ1601060TS |

Hexagon Head Bolt |

8 |

| 11 |

Q18518140T |

Hexagon Head Flange Bolt |

2 |

| 12 |

1001065-50V |

Rear Suspension Bracket Cushion Assembly |

2 |

| 13 |

1001063-483 |

Upper Cushion Plate – Engine Rear Suspension |

2 |

| 14 |

1001079-263 |

Bottom Plate – Rear Suspension |

2 |

| 15 |

Q32918T |

Type 1 Non-metallic Insert Hexagon Lock Nut |

2 |

| 16 |

1001064-64W |

Rear Suspension Cushion Plate |

2 |

| 17 |

Q1841450TS |

Hexagon Flange Bolt (Coarse Shank/Standard) |

4 |

| 18 |

Q1841460TS |

Hexagon Flange Bolt (Coarse Shank/Standard) |

4 |

Diagnostic Protocols for Engine Suspension

Effective maintenance of the FAW Russian Engine Mounting Logic begins with visual inspection. The rubber components, specifically the Engine Front Suspension Cushion Assembly and the Rear Suspension Bracket Cushion Assembly, are the wear items most susceptible to degradation. In the Russian climate, look for signs of “checking” or micro-cracks on the rubber surface, which indicate ozone damage or dry rot. Severe cracks or separation between the rubber and the metal bonding plates require immediate replacement of the unit. Operating with a collapsed mount will transmit excessive vibration, potentially cracking the radiator mounts or exhaust manifolds.

Torque verification is another pillar of the maintenance schedule. The Hexagon Head Flange Bolts securing the brackets to the block are subject to high-frequency vibration. While the Type 1 Non-metallic Insert Hexagon Lock Nuts are designed to resist loosening, they are not infallible. It is recommended to check the torque on these fasteners during every major service interval. If a bolt is found loose, do not simply retighten it; inspect the threads for damage and replace the locking nut, as the nylon insert loses its effectiveness after being torqued and loosened multiple times.

Finally, inspect the geometry of the engine position. If the FAW Russian Engine Mounting Logic is functioning correctly, the engine should sit level and the fan should be centered within the shroud. A sagging engine often indicates that the internal structure of the cushion has failed, even if the exterior looks intact. Measuring the clearance between the Bottom Plate – Rear Suspension and the chassis rail can provide a definitive indication of mount collapse. Proactive replacement of these mounts preserves the drivetrain alignment and extends the life of the entire vehicle.

Conclusion: The Foundation of Reliability

The FAW Russian Engine Mounting Logic is more than just a set of bolts and rubber pads; it is a meticulously engineered system designed to harmonize the operation of a massive diesel engine with the structural realities of a heavy-duty truck. From the metallurgy of the Engine Front Suspension Bracket to the elasticity of the cushion assemblies, every component plays a role in ensuring the longevity of the CA3250P66K24L1TE5Z.

For fleet operators, understanding this system is key to reducing operational costs. Neglecting engine mounts leads to a cascade of secondary failures that are far more expensive to repair than the mounts themselves. By investing in genuine FAW parts and adhering to a strict inspection regimen, you ensure that your fleet remains capable of conquering the toughest roads and the coldest winters that the Russian Federation has to offer.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.