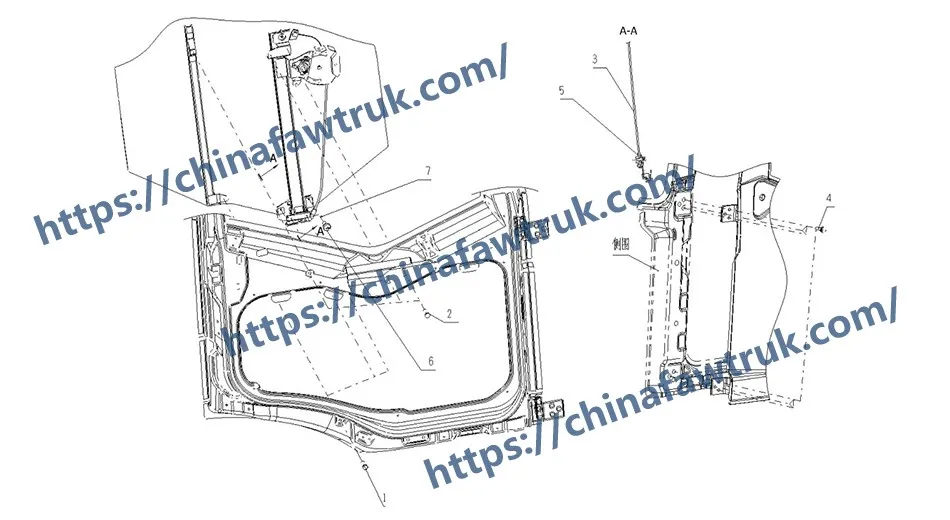

Welcome to this definitive technical guide on the FAW J6P Lifting Device, also known as the window regulator, for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck. This analysis deconstructs the 7 critical component types that make up this essential electro-mechanical system.

The FAW J6P Lifting Device is the core “muscle” inside the truck’s door, responsible for raising and lowering the heavy front door glass. This system must provide high torque, precise control, and extreme reliability. It is engineered to withstand the high-vibration environment of a construction site and the high-use cycle of a daily-driven vehicle. This guide will analyze the core regulator assembly, the glass it lifts, and all specialized, vibration-proof fasteners.

This component is the heart and namesake of the FAW J6P Lifting Device system. It is a sealed, pre-assembled electro-mechanical unit that provides the force to move the window.

1. Component: ‘Left/Right front door electric window regulator assembly’ (6104025AA01 / 6104030AA01) – Qty 1 each

This (Comp 5) is the core assembly. It includes a high-torque 12V DC electric motor, a self-locking worm gear drive, and a steel “scissor-lift” mechanism.

The Electric Logic is what provides the power. The motor is activated by the driver’s switch, turning a worm gear. This gearbox multiplies the motor’s torque significantly, allowing it to easily lift the heavy tempered glass. A key feature is the worm drive, which is self-locking. This means the window cannot be physically pushed down from the outside, providing security.

The Mechanical Logic lies in the “scissor-lift” design. This is the “X” shaped set of stamped steel arms that converts the motor’s rotational force into a perfectly vertical, stable lift. This mechanism is responsible for pushing the glass up and guiding it down without letting it tilt or bind.

This entire FAW J6P Lifting Device is the central component within the door. It mounts to the door’s structural guide rails, and the glass panel (Comp 3) bolts directly to its “saddle.” This assembly is the most common point of failure, typically from motor burnout or a snapped cable in the lift mechanism.

This group represents the specialized hardware—20 pieces in total—that rigidly secures the FAW J6P Lifting Device (Comp 5) to the door’s inner frame and guide rails.

1. Component: ‘Combination bolt’ (CQ1461035) – Qty 12

These (Comp 4) are the primary structural bolts. The “combination” name signifies they have a pre-installed, captive spring lock washer. This is a critical anti-vibration feature. These 12 bolts (6 per door) secure the main body of the regulator to the door’s inner guide rails.

2. Component: ‘Cross recessed countersunk head screw’ (Q2540622S) – Qty 4

3. Component: ‘Outer-serrated locking washer’ (Q41206) – Qty 4

This (Comp 6 and 7) is a two-part, high-strength fastener set. The countersunk screw sits flush in the guide rail, while the ‘outer-serrated’ washer provides an aggressive locking action. Its teeth bite into both the screw and the frame, making it impossible for vibration to loosen the connection.

The Vibration-Proof Logic is the unifying principle here. A loose FAW J6P Lifting Device would rattle and, more importantly, would misalign, causing the window to jam. Every fastener used—both the combination bolts and the serrated washer sets—is specifically chosen to lock the threads and withstand the severe, constant vibration of a dump truck.

This component is not part of the FAW J6P Lifting Device itself, but it is the “load” that the device is designed to move. The entire system is engineered around the weight and shape of this part.

1. Component: ‘Left/Right front door glass’ (6103021-A01 / 6103022-A01) – Qty 1 each

This (Comp 3) is the tempered safety glass panel. Its significant weight is the primary factor in determining the required torque for the regulator’s motor (Comp 5).

The Interaction Logic is crucial. The glass has precision-drilled mounting holes at the bottom. These holes align perfectly with the “saddle” of the FAW J6P Lifting Device, allowing it to be securely bolted on.

Furthermore, the polished edges and slight curvature of the glass are designed to interact with the door’s flocked guide channels. Any friction in those channels (e.g., from wear or dirt) increases the “load” on the FAW J6P Lifting Device, reducing its service life. A failed regulator is often a symptom of worn-out, high-friction guide channels.

This final group of 12 fasteners is responsible for the single most critical connection: attaching the glass panel (the load) to the FAW J6P Lifting Device (the muscle).

1. Component: ‘Cross recessed flat round head combination screw’ (Q2360612F6) – Qty 6

2. Component: ‘Cross recessed flat round head combination screw’ (Q2360612) – Qty 6

These two sets (Comp 1 and 2), while having slightly different part numbers, serve the same function. They are the 12 screws (6 per door) that pass through the glass panel and secure it to the regulator’s saddle.

The Clamping Logic must be precise. These screws are designed to be torqued to a specific value. They clamp the glass against the regulator, usually with a rubber or nylon grommet in between to prevent a glass-on-metal stress point.

The “Combination” screw design, with its built-in locking washer, is absolutely essential here. These screws are subjected to the entire “push” and “pull” force from the FAW J6P Lifting Device, plus the jarring shock of every door slam. A standard screw would back out in days. The locking washer maintains constant tension, ensuring the glass never loosens from its lifting mechanism.

The following table provides the complete, detailed breakdown of all 7 component types in the FAW J6P Lifting Device and window assembly (System 146) for the FAW Jiefang CA3250P66K2L1T1E 6×4 dump truck.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | Q2360612F6 | Cross recessed flat round head combination screw | 6 |

| 2 | Q2360612 | Cross recessed flat round head combination screw | 6 |

| 3 | 6103021-A01 | Left front door glass | 1 |

| 3 | 6103022-A01 | Right front door glass | 1 |

| 4 | CQ1461035 | Combination bolt | 12 |

| 5 | 6104025AA01 | Left front door electric window regulator assembly | 1 |

| 5 | 6104030AA01 | Right front door electric window regulator assembly | 1 |

| 6 | Q2540622S | Cross recessed countersunk head screw | 4 |

| 7 | Q41206 | Outer-serrated locking washer | 4 |

The specifications for the FAW J6P Lifting Device are defined by its function as the primary motor and regulator for the door window.

| Vehicle Application | FAW Jiefang CA3250P66K2L1T1E 6×4 Dump Truck |

| System Group | FAW J6P Lifting Device (Window Regulator) |

| Assembly Reference | 146 |

| Primary Logic | Electro-Mechanical Glass Lift & Positioning |

| Core Component | ‘Left/Right… electric window regulator assembly’ (6104025AA01 / …30AA01) |

| Motive Type | Electric 12V DC Motor with Scissor-Lift |

| Associated Load | ‘Left/Right front door glass’ (6103021-A01 / …22-A01) |

| Regulator Fasteners | ‘Combination bolt’ (CQ1461035) & ‘Countersunk screw’ (Q2540622S) |

| Glass Fasteners | ‘Combination screw’ (Q2360612F6 / Q2360612) |

| Total Component Types | 7 |

| Associated System | Front Door Window Guide Rail (System 145), Door-in-White |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.