Welcome to this in-depth technical breakdown of the Ensemble logique d'instrumentation combinée FAW. This component is the single most important Human-Machine Interface (IHM) for the driver of the FAW Jiefang CA4251P66K24T1A3E5 6×4 tracteur semi-remorque diesel. It is the driver’s “fenêtre” into the health and status of the entire vehicle, responsible for displaying everything from road speed and air pressure to critical “stop engine” avertissements.

Le “Assemblage logique” designation is key. Ce composant (Réf.: 3820010-90W-C00) is not a set of simple, analog gauges. It is a sophisticated Electronic Control Unit (ECU) in its own right. Le Ensemble logique d'instrumentation combinée FAW “écoute” to the vehicle’s high-speed CAN bus network, receiving digital data packets from the Engine ECU, le module ABS/EBS, et le module de contrôle du corps (BCM). C'est “logique” is to interpret this stream of data and translate it into clear, human-readable information via analog pointers, a digital LCD screen, and over 10 critical warning tell-tales.

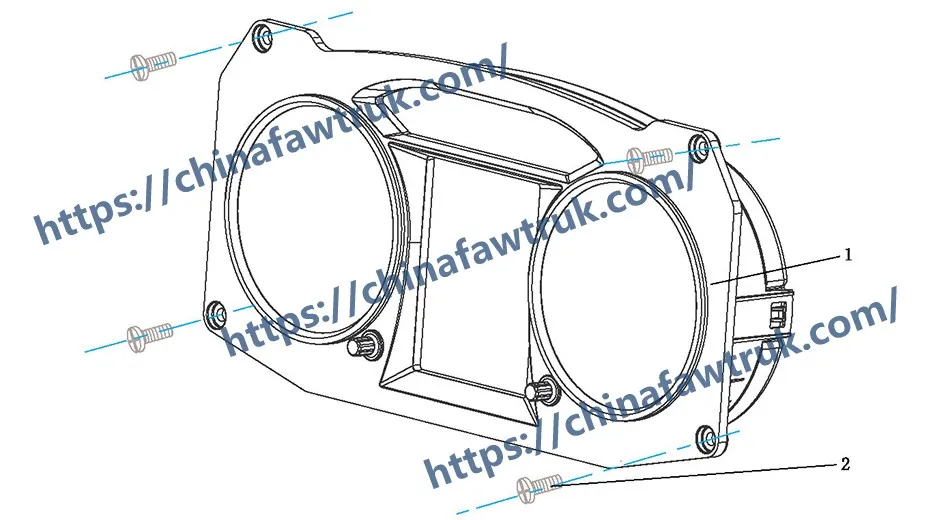

This guide is essential for technicians and parts managers. This is a very simple assembly, comprised of only two component types. We will deconstruct the “boîte noire” logic of the main ‘Combination instrumentation assy’ lui-même, l'identifiant comme l'unité minimale utilisable principale (MSU). Nous analyserons également les vis autotaraudeuses spécifiques à tête cylindrique à empreinte cruciforme’ (CQ2714216) utilisé pour le monter, which is the second critical MSU.

Ce composant est le “plus long” and most critical part of the Ensemble logique d'instrumentation combinée FAW. The ‘Combination instrumentation assy’ (3820010-90W-C00) est un scellé, “boîte noire” unité. It is the primary Minimum Serviceable Unit (MSU), meaning it is not designed to be repaired in the field. If a gauge fails, a warning light burns out (as they are all integrated LEDs), or the LCD screen cracks, the entire assembly is replaced as one part.

Le “logique” of this assembly is to be the central data interpreter for the driver. It performs this logic in three ways: receiving data, processing it, and displaying it.

1. Data Reception “Logique” (Listening)

Le Ensemble logique d'instrumentation combinée FAW is a major “node” on the vehicle’s Controller Area Network (Bus CAN). This J1939-compliant network is a two-wire digital highway where all the truck’s ECUs communicate. The cluster “écoute” to this network and plucks out the messages it needs.

2. Data Display “Logique” (Speaking)

Once the data is received, the cluster’s internal processor translates it into a human-readable format. This display logic is what makes the Ensemble logique d'instrumentation combinée FAW so critical.

Analog Gauges: These are the large physical needles that provide “at a glance” information.

Warning Telltales (Le 10+ Warnings): C'est le “logique” of safety. Le Ensemble logique d'instrumentation combinée FAW has a panel of non-serviceable LEDs (replacing old bulbs) that illuminate to provide instant, impossible-to-miss warnings. These are divided by color:

Digital LCD Screen: This central screen provides detailed text-based information, such as the Odometer (total mileage), Trip Meter, and specific Diagnostic Trouble Codes (DTC). This screen is the primary diagnostic interface for the driver.

The second and final component of the Ensemble logique d'instrumentation combinée FAW is the mounting hardware. La liste des pièces en appelle quatre (4) ‘Cross recessed pan head self-tapping screws’ (CQ2714216).

Logique de fixation: These are not standard machine screws. Le “autotaraudeuse” designation is the key “logique.” These screws are designed to be driven directly into the plastic mounting bosses of the dashboard’s sub-structure. They are hardened and designed to cut their own threads as they are installed.

This design greatly simplifies the manufacturing and assembly process, as no “noix” ou “agrafe” is required on the backside. Pour un technicien, this means service is simpler, comme l'ensemble Ensemble logique d'instrumentation combinée FAW can be removed from the front after taking off the dash bezel.

These screws are a critical MSU. Their specific thread pitch and length are designed for the plastic boss. Using the wrong screw (Par exemple, a machine screw or a different thread) will strip the plastic mounting boss and fail to secure the cluster, conduisant à des vibrations, cliquetis, and potential damage to the cluster’s sensitive electronics.

Le tableau suivant fournit l'intégralité, ventilation détaillée de tous 2 types de composants identifiés dans le Ensemble logique d'instrumentation combinée FAW schéma du tracteur FAW CA4251P66K24T1A3E5.

| Marque | Partie no. | Nom de la pièce | Quantité |

|---|---|---|---|

| 1 | 3820010-90W-C00 | Combination instrumentation assy | 1 |

| 2 | CQ2714216 | Vis autotaraudeuse à tête cylindrique à empreinte cruciforme | 4 |

Les spécifications pour le Ensemble logique d'instrumentation combinée FAW are defined by its function as the primary HMI and data processing node for the driver. C'est un point critique, non-repairable electronic module.

| Demande de véhicule | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tracteur |

| Groupe de composants | Ensemble logique d'instrumentation combinée FAW |

| Assemblage principal P/N | 3820010-90W-C00 |

| Type de système | Electronic Instrument Cluster / HMI Display |

| Tension du système | 24À DC (Nominal) |

| Data Interface | CAN-Bus (J1939), Analog Sensor Inputs (Carburant, Air) |

| Display Logic | Analog Gauges (Tach/Speed/Air/Fuel/Temp), LED Telltales, Digital LCD |

| Warning Indicators | 10+ LED Telltales (Red/Amber/Green/Blue) |

| MSU 1 (Principal) | ‘Combination instrumentation assy’ (Unité scellée) |

| MSU 2 (Matériel) | « Vis autotaraudeuse à tête cylindrique à empreinte cruciforme’ (CQ2714216) |

| MSU 2 Quantité | 4 |

| Facilité d'entretien | Unit-level replacement only. Not field-repairable. |

Pièces FAW, y compris l'ensemble bloc-cylindres, sont emballés avec soin pour garantir une livraison en toute sécurité. Chaque composant est sécurisé dans des matériaux de protection pour éviter tout dommage pendant le transport. Le réseau logistique garantit des expéditions ponctuelles dans le monde entier, soutenir des opérations de maintenance efficaces. Vous trouverez ci-dessous une image illustrant l'emballage standard des pièces de camion FAW., mettant en valeur l’attention portée aux détails dans la manipulation et le stockage.

Cette approche d'emballage minimise le risque de corrosion ou de dommages causés par les chocs., s'assurer que les pièces comme l'ensemble bloc-cylindres FAW arrivent en parfait état. Les clients peuvent compter sur la logistique de FAW pour une qualité et une fiabilité constantes.