Welcome to this in-depth technical breakdown of the FAW Combination Instrumentation Logic Assembly. This component is the single most important Human-Machine Interface (HMI) for the driver of the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. It is the driver’s “window” into the health and status of the entire vehicle, responsible for displaying everything from road speed and air pressure to critical “stop engine” warnings.

The “Logic Assembly” designation is key. This component (P/N: 3820010-90W-C00) is not a set of simple, analog gauges. It is a sophisticated Electronic Control Unit (ECU) in its own right. The FAW Combination Instrumentation Logic Assembly “listens” to the vehicle’s high-speed CAN bus network, receiving digital data packets from the Engine ECU, the ABS/EBS module, and the Body Control Module (BCM). Its “logic” is to interpret this stream of data and translate it into clear, human-readable information via analog pointers, a digital LCD screen, and over 10 critical warning tell-tales.

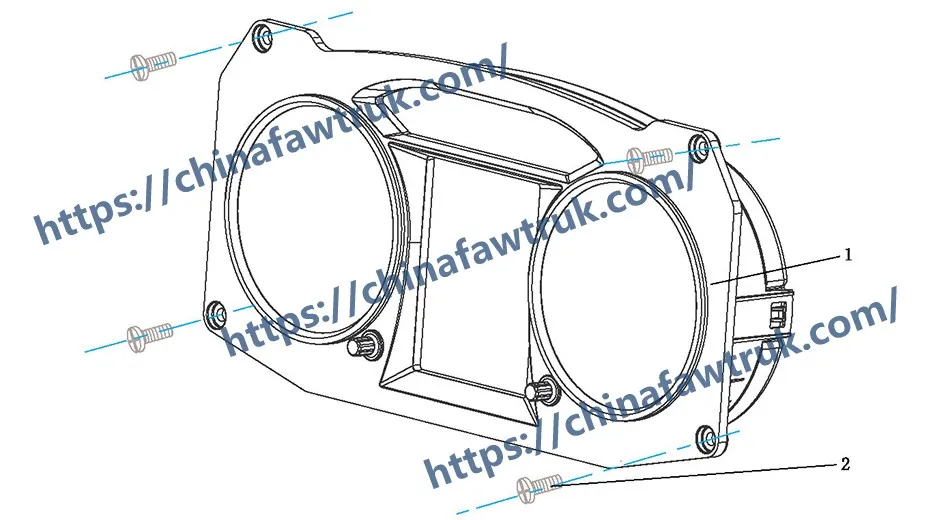

This guide is essential for technicians and parts managers. This is a very simple assembly, comprised of only two component types. We will deconstruct the “black box” logic of the main ‘Combination instrumentation assy’ itself, identifying it as the primary Minimum Serviceable Unit (MSU). We will also analyze the specific ‘Cross recessed pan head self-tapping screw’ (CQ2714216) used to mount it, which is the second critical MSU.

This component is the “longer” and most critical part of the FAW Combination Instrumentation Logic Assembly. The ‘Combination instrumentation assy’ (3820010-90W-C00) is a sealed, “black box” unit. It is the primary Minimum Serviceable Unit (MSU), meaning it is not designed to be repaired in the field. If a gauge fails, a warning light burns out (as they are all integrated LEDs), or the LCD screen cracks, the entire assembly is replaced as one part.

The “logic” of this assembly is to be the central data interpreter for the driver. It performs this logic in three ways: receiving data, processing it, and displaying it.

1. Data Reception “Logic” (Listening)

The FAW Combination Instrumentation Logic Assembly is a major “node” on the vehicle’s Controller Area Network (CAN bus). This J1939-compliant network is a two-wire digital highway where all the truck’s ECUs communicate. The cluster “listens” to this network and plucks out the messages it needs.

2. Data Display “Logic” (Speaking)

Once the data is received, the cluster’s internal processor translates it into a human-readable format. This display logic is what makes the FAW Combination Instrumentation Logic Assembly so critical.

Analog Gauges: These are the large physical needles that provide “at a glance” information.

Warning Telltales (The 10+ Warnings): This is the “logic” of safety. The FAW Combination Instrumentation Logic Assembly has a panel of non-serviceable LEDs (replacing old bulbs) that illuminate to provide instant, impossible-to-miss warnings. These are divided by color:

Digital LCD Screen: This central screen provides detailed text-based information, such as the Odometer (total mileage), Trip Meter, and specific Diagnostic Trouble Codes (DTCs). This screen is the primary diagnostic interface for the driver.

The second and final component of the FAW Combination Instrumentation Logic Assembly is the mounting hardware. The parts list calls for four (4) ‘Cross recessed pan head self-tapping screws’ (CQ2714216).

Fastener Logic: These are not standard machine screws. The “self-tapping” designation is the key “logic.” These screws are designed to be driven directly into the plastic mounting bosses of the dashboard’s sub-structure. They are hardened and designed to cut their own threads as they are installed.

This design greatly simplifies the manufacturing and assembly process, as no “nut” or “clip” is required on the backside. For a technician, this means service is simpler, as the entire FAW Combination Instrumentation Logic Assembly can be removed from the front after taking off the dash bezel.

These screws are a critical MSU. Their specific thread pitch and length are designed for the plastic boss. Using the wrong screw (e.g., a machine screw or a different thread) will strip the plastic mounting boss and fail to secure the cluster, leading to vibration, rattling, and potential damage to the cluster’s sensitive electronics.

The following table provides the complete, detailed breakdown of all 2 component types identified in the FAW Combination Instrumentation Logic Assembly diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 3820010-90W-C00 | Combination instrumentation assy | 1 |

| 2 | CQ2714216 | Cross recessed pan head self-tapping screw | 4 |

The specifications for the FAW Combination Instrumentation Logic Assembly are defined by its function as the primary HMI and data processing node for the driver. It is a critical, non-repairable electronic module.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Combination Instrumentation Logic Assembly |

| Main Assembly P/N | 3820010-90W-C00 |

| System Type | Electronic Instrument Cluster / HMI Display |

| System Voltage | 24V DC (Nominal) |

| Data Interface | CAN Bus (J1939), Analog Sensor Inputs (Fuel, Air) |

| Display Logic | Analog Gauges (Tach/Speed/Air/Fuel/Temp), LED Telltales, Digital LCD |

| Warning Indicators | 10+ LED Telltales (Red/Amber/Green/Blue) |

| MSU 1 (Main) | ‘Combination instrumentation assy’ (Sealed Unit) |

| MSU 2 (Hardware) | ‘Cross recessed pan head self-tapping screw’ (CQ2714216) |

| MSU 2 Quantity | 4 |

| Serviceability | Unit-level replacement only. Not field-repairable. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.