Bem-vindo a esta análise técnica detalhada do Conjunto lógico de instrumentação combinada FAW. This component is the single most important Human-Machine Interface (IHM) for the driver of the FAW Jiefang CA4251P66K24T1A3E5 6×4 trator semirreboque diesel. It is the driver’s “janela” into the health and status of the entire vehicle, responsible for displaying everything from road speed and air pressure to critical “stop engine” avisos.

O “Montagem Lógica” designation is key. Este componente (P/N: 3820010-90W-C00) is not a set of simple, analog gauges. It is a sophisticated Electronic Control Unit (ECU) in its own right. O Conjunto lógico de instrumentação combinada FAW “escuta” to the vehicle’s high-speed CAN bus network, receiving digital data packets from the Engine ECU, o módulo ABS/EBS, e o Módulo de Controle Corporal (BCM). Isso é “lógica” is to interpret this stream of data and translate it into clear, human-readable information via analog pointers, a digital LCD screen, and over 10 critical warning tell-tales.

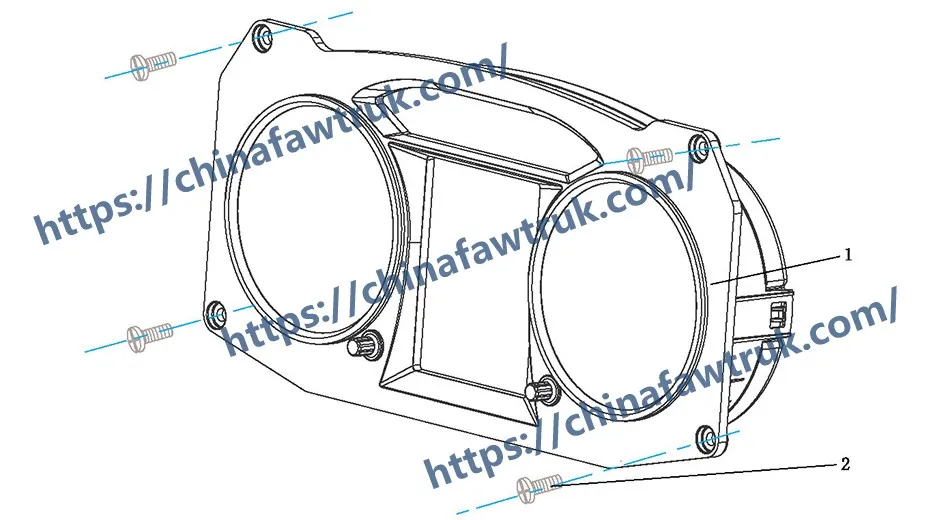

This guide is essential for technicians and parts managers. This is a very simple assembly, comprised of only two component types. We will deconstruct the “caixa preta” logic of the main ‘Combination instrumentation assy’ em si, identificando-a como a Unidade Mínima de Manutenção primária (Universidade Estadual de Moscou). Também analisaremos o específico 'parafuso auto-roscante de cabeça panela com recesso cruzado’ (CQ2714216) usado para montá-lo, which is the second critical MSU.

Este componente é o “mais longo” and most critical part of the Conjunto lógico de instrumentação combinada FAW. The ‘Combination instrumentation assy’ (3820010-90W-C00) é um selado, “caixa preta” unidade. It is the primary Minimum Serviceable Unit (Universidade Estadual de Moscou), meaning it is not designed to be repaired in the field. If a gauge fails, a warning light burns out (as they are all integrated LEDs), or the LCD screen cracks, the entire assembly is replaced as one part.

O “lógica” of this assembly is to be the central data interpreter for the driver. It performs this logic in three ways: receiving data, processing it, and displaying it.

1. Data Reception “Lógica” (Listening)

O Conjunto lógico de instrumentação combinada FAW is a major “node” on the vehicle’s Controller Area Network (CAN bus). This J1939-compliant network is a two-wire digital highway where all the truck’s ECUs communicate. The cluster “escuta” to this network and plucks out the messages it needs.

2. Data Display “Lógica” (Speaking)

Once the data is received, the cluster’s internal processor translates it into a human-readable format. This display logic is what makes the Conjunto lógico de instrumentação combinada FAW so critical.

Analog Gauges: These are the large physical needles that provide “at a glance” Informação.

Warning Telltales (O 10+ Warnings): Este é o “lógica” of safety. O Conjunto lógico de instrumentação combinada FAW has a panel of non-serviceable LEDs (replacing old bulbs) that illuminate to provide instant, impossible-to-miss warnings. These are divided by color:

Digital LCD Screen: This central screen provides detailed text-based information, such as the Odometer (total mileage), Trip Meter, and specific Diagnostic Trouble Codes (DTCs). This screen is the primary diagnostic interface for the driver.

The second and final component of the Conjunto lógico de instrumentação combinada FAW é o hardware de montagem. A lista de peças pede quatro (4) ‘Cross recessed pan head self-tapping screws’ (CQ2714216).

Lógica do Fixador: These are not standard machine screws. O “auto-roscante” designation is the key “lógica.” These screws are designed to be driven directly into the plastic mounting bosses of the dashboard’s sub-structure. They are hardened and designed to cut their own threads as they are installed.

This design greatly simplifies the manufacturing and assembly process, as no “noz” ou “grampo” is required on the backside. Para um técnico, this means service is simpler, as the entire Conjunto lógico de instrumentação combinada FAW can be removed from the front after taking off the dash bezel.

These screws are a critical MSU. Their specific thread pitch and length are designed for the plastic boss. Using the wrong screw (Por exemplo, a machine screw or a different thread) will strip the plastic mounting boss and fail to secure the cluster, levando à vibração, chocalho, and potential damage to the cluster’s sensitive electronics.

A tabela a seguir fornece o completo, detalhamento de todos 2 tipos de componentes identificados no Conjunto lógico de instrumentação combinada FAW diagrama para o trator FAW CA4251P66K24T1A3E5.

| Marca | Parte não. | Nome da peça | Quantidade |

|---|---|---|---|

| 1 | 3820010-90W-C00 | Combination instrumentation assy | 1 |

| 2 | CQ2714216 | Parafuso auto-roscante de cabeça panela com recesso cruzado | 4 |

As especificações para o Conjunto lógico de instrumentação combinada FAW are defined by its function as the primary HMI and data processing node for the driver. É uma crítica, non-repairable electronic module.

| Aplicação em veículos | FAW Jiefang CA4251P66K24T1A3E5 6×4 Trator |

| Grupo de Componentes | Conjunto lógico de instrumentação combinada FAW |

| Conjunto principal P/N | 3820010-90W-C00 |

| Tipo de sistema | Electronic Instrument Cluster / HMI Display |

| Tensão do sistema | 24Em DC (Nominal) |

| Data Interface | Ônibus CAN (J1939), Analog Sensor Inputs (Combustível, Ar) |

| Display Logic | Analog Gauges (Tach/Speed/Air/Fuel/Temp), LED Telltales, Digital LCD |

| Warning Indicators | 10+ LED Telltales (Red/Amber/Green/Blue) |

| Universidade Estadual de Moscou 1 (Principal) | ‘Combination instrumentation assy’ (Unidade Selada) |

| Universidade Estadual de Moscou 2 (Hardware) | 'Parafuso auto-roscante de cabeça panela com recesso cruzado’ (CQ2714216) |

| Universidade Estadual de Moscou 2 Quantidade | 4 |

| Facilidade de manutenção | Unit-level replacement only. Not field-repairable. |

Peças FAW, incluindo o conjunto do bloco de cilindros, são embalados com cuidado para garantir uma entrega segura. Cada componente é protegido por materiais de proteção para evitar danos durante o transporte. A rede logística garante envios pontuais em todo o mundo, apoiando operações de manutenção eficientes. Abaixo está uma imagem ilustrando a embalagem padrão para peças de caminhão FAW, mostrando a atenção aos detalhes no manuseio e armazenamento.

Esta abordagem de embalagem minimiza o risco de corrosão ou danos por impacto, garantindo que peças como o conjunto do bloco de cilindros FAW cheguem em perfeitas condições. Os clientes podem confiar na logística da FAW para obter qualidade e confiabilidade consistentes.