FAW Russian Windscreen Washer Assembly: 4 Components Delivering High-Pressure Cleaning in Arctic Conditions

The FAW Russian Windscreen Washer assembly is the essential companion to the wiper system on the CA3250P66K24L1TE5Z dump truck. In the Russian environment, where roads are coated in a sticky mixture of mud, salt, and de-icing chemicals, wipers alone are often insufficient. This high-capacity washer system delivers a powerful spray of cleaning fluid to dissolve grime instantly, allowing the wipers to clear the glass effectively. Designed with a freeze-resistant pump and durable reservoir, the FAW Russian Windscreen Washer ensures that the driver can maintain visibility even when following other vehicles on slushy highways.

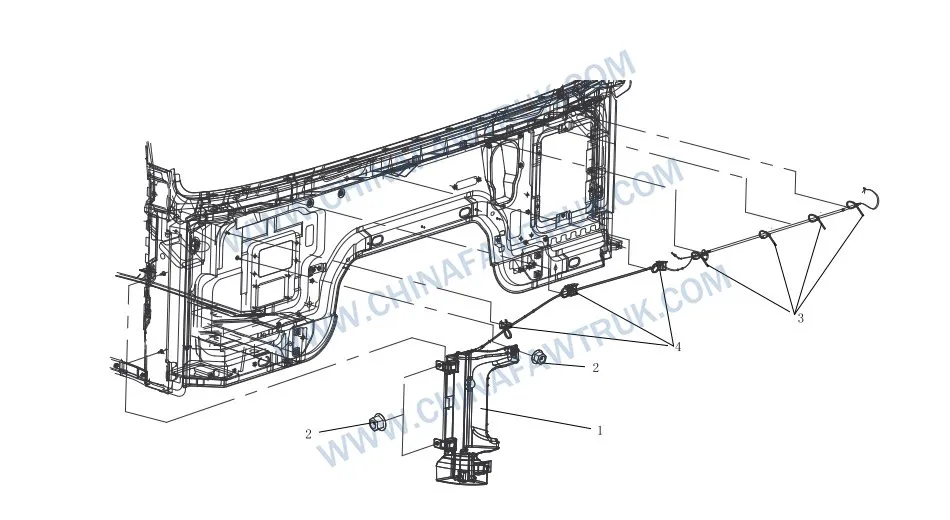

FAW Russian Windscreen Washer

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5207010BA01 | Washer Assembly | 1 |

| 2 | CQ32606 | Hexagon Head Flange Lock Nut | 3 |

| 3 | T67414646 | Plastic Band | 4 |

| 4 | 3724012-A01 | T-Type Wiring Harness Clip II | 3 |

Reservoir Capacity and Pump Performance

The heart of the FAW Russian Windscreen Washer system is the Washer Assembly (Part No. 5207010BA01). This unit integrates a large-capacity fluid reservoir with a high-pressure electric pump. For the Russian market, capacity is key; frequent washing is required on long hauls, and running dry is a major inconvenience. The tank is molded from impact-resistant polyethylene that can expand without cracking if the washer fluid freezes, a common occurrence if the incorrect mixture is used.

The electric pump within the FAW Russian Windscreen Washer assembly is designed to generate sufficient pressure to blast through the boundary layer of air on the windshield at highway speeds. Weak pumps result in the spray hitting the bottom of the glass or being blown over the roof. The FAW pump ensures that the cleaning fluid reaches the critical swept area of the wipers, maximizing the cleaning efficiency.

Furthermore, the Washer Assembly typically includes a fluid level sensor (or a provision for one). This alerts the driver via a dashboard warning light when the reservoir is low. In the dusty and muddy conditions of a mine, running out of washer fluid can essentially blind the driver. This early warning system is a vital safety feature of the FAW Russian Windscreen Washer logic.

Secure Mounting and Vibration Resistance

A full washer reservoir is heavy, weighing several kilograms. To secure this dynamic load against the chassis vibration, the FAW Russian Windscreen Washer uses 3 units of the Hexagon Head Flange Lock Nut (Part No. CQ32606). These nuts secure the reservoir to the cab bulkhead or inner fender. The flange design spreads the clamping load over the plastic mounting tabs of the tank, preventing stress cracks that could lead to leaks.

The locking feature of these nuts is essential. As the truck bounces over rough terrain, the fluid inside the tank sloshes violently, creating cyclical loads on the fasteners. Standard nuts would back off quickly. The FAW Russian Windscreen Washer relies on these lock nuts to ensure that the reservoir remains rigidly attached for the life of the vehicle.

Proper mounting also protects the pump motor. If the tank were loose, the electrical connector and fluid lines attached to the pump would be subjected to strain, leading to premature failure. The secure installation provided by the lock nuts is fundamental to the reliability of the entire FAW Russian Windscreen Washer system.

Hose Routing and Management

Delivering fluid from the reservoir to the nozzles requires a network of flexible tubing. The FAW Russian Windscreen Washer kit includes Plastic Band (Part No. T67414646) and T-Type Wiring Harness Clip II (Part No. 3724012-A01) to manage these lines. The tubing must be routed carefully to avoid hot engine components and sharp metal edges that could melt or chafe the plastic.

The T-Type Wiring Harness Clip II is particularly useful for securing the washer hose to existing wiring looms or brake lines, keeping the engine bay tidy. In the Russian winter, these hoses become stiff and brittle. Proper securing with the Plastic Band prevents them from vibrating and snapping at the connections.

Furthermore, the routing logic ensures that there are no low spots where fluid can accumulate and freeze, blocking the line. The FAW Russian Windscreen Washer system is designed with gravity drainage or check valves in mind to maintain a primed line without freezing risk, ensuring instant spray when the button is pressed.

Maintenance and Fluid Choice

For optimal performance, the FAW Russian Windscreen Washer must be filled with a winter-grade washer fluid capable of remaining liquid at -40°C. Using plain water or summer fluid will result in the reservoir, pump, and lines freezing solid, potentially cracking the Washer Assembly housing. Fleet managers should check the fluid concentration regularly with a refractometer.

Periodically, the reservoir should be flushed to remove sediment that can clog the pump intake screen or the washer nozzles. The FAW Russian Windscreen Washer pump is robust, but it cannot pass large particles. If the spray pattern becomes weak or uneven, check for kinked hoses or clogged nozzles before replacing the pump.

Using genuine FAW replacement parts ensures that the pump pressure and flow rate match the nozzle design. Aftermarket pumps may be too weak or draw excessive current, blowing fuses. The genuine Washer Assembly is built to the specific electrical and hydraulic requirements of the J6P, providing reliable cleaning power for the long haul.

Conclusion: Essential for Arctic Visibility

The FAW Russian Windscreen Washer assembly is a vital safety system comprising the reservoir, pump, and securing hardware. While simple in concept, its role in maintaining driver visibility in the harsh Russian climate is critical. The 4 components listed work together to deliver reliable cleaning performance on demand.

For fleet operators, maintaining the FAW Russian Windscreen Washer is a low-cost, high-impact safety measure. Ensuring the tank is full of correct fluid and the system is leak-free keeps the truck operational when conditions deteriorate. By prioritizing this system, operators ensure that their drivers can always see the road ahead, preventing accidents and improving efficiency.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.