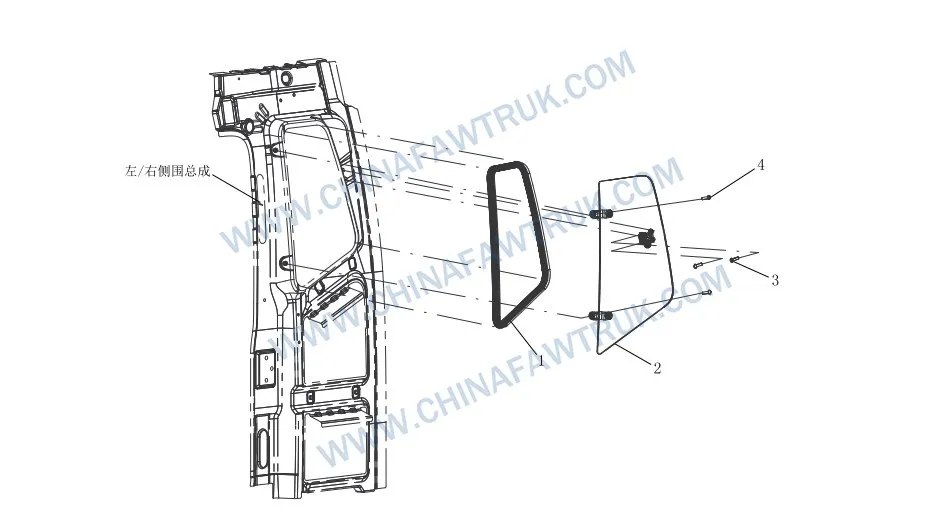

FAW Russian Side-Opening Window Glass: 4 Essential Components for Arctic Cabin Ventilation and Clarity

The FAW Russian Side-Opening Window Glass assembly is a vital architectural feature of the CA3250P66K24L1TE5Z dump truck’s cabin. Unlike fixed glazing, this operational unit allows drivers to control cabin ventilation manually without relying solely on the HVAC system. In the Russian Arctic, where condensation buildup can obscure visibility instantly, the ability to crack a window safely is crucial. This assembly combines tempered safety glass, weather-resistant sealing strips, and specialized fasteners to create a portal that is both secure against the elements and easy to operate. The FAW Russian Side-Opening Window Glass maintains the thermal envelope of the cab while providing a necessary connection to the outside world.

FAW Russian Side-Opening Window Glass

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5403051-A01 | Left Seal Strip – Side Window Glass | 1 |

| 5403052-A01 | Right Seal Strip – Side Window Glass (See 5403051-A01) | 1 |

| 2 | 5403015-A86 | Left Opening Side Window Assembly | 1 |

| 5403020-A86 | Right Opening Side Window Assembly (See 5403015-A86) | 1 |

| 3 | CQ2180620F6 | Hexagon Socket Head Cap Screw | 4 |

| 4 | Q2360620 | Cross Recessed Pan Head Screw and Washer Assembly | 4 |

Core Assembly: The Opening Window Unit

The centerpiece of the FAW Russian Side-Opening Window Glass system is the Left Opening Side Window Assembly (Part No. 5403015-A86) and its counterpart, the Right Opening Side Window Assembly (Part No. 5403020-A86). These units are fully integrated modules that include the glass pane, the perimeter frame, and the latching mechanism. In the CA3250 dump truck, these windows are typically located in the rear quarter of the cab or the sleeper section, providing cross-ventilation that is essential when the truck is parked with the engine off.

The glass used in the FAW Russian Side-Opening Window Glass is tempered safety glass. This material is treated to withstand significant thermal shock—a common occurrence when the interior temperature is +20°C and the exterior is -40°C. If shattered by an impact from mining debris, the glass crumbles into small, blunt granules rather than sharp shards, protecting the driver from injury. The “A86” specification indicates a tint level optimized for reducing snow glare, a critical feature for reducing eye strain during daytime operations in the stark white landscape of the Russian winter.

The frame of the Opening Side Window Assembly is constructed from extruded aluminum or high-strength polymer, coated with a durable matte black finish. This frame provides the structural rigidity needed to compress the seals against the cab body. It also houses the hinge and latch pivots. In the FAW Russian Side-Opening Window Glass design, these pivots are engineered with tight tolerances to prevent the window from rattling or vibrating open on rough haul roads, ensuring a quiet and secure cabin environment.

Sealing Technology: The Defense Against Drafts

The effectiveness of the FAW Russian Side-Opening Window Glass relies entirely on the integrity of its seals. The assembly utilizes the Left Seal Strip – Side Window Glass (Part No. 5403051-A01) and the Right Seal Strip – Side Window Glass (Part No. 5403052-A01). These are not generic rubber gaskets; they are precision-molded EPDM (Ethylene Propylene Diene Monomer) profiles designed to fit the specific curvature of the J6P window aperture. EPDM is chosen for its exceptional resistance to weathering, UV radiation, and ozone, ensuring the seal does not crack or shrink after years of exposure.

In the extreme cold of the Russian North, standard rubber becomes hard and brittle, losing its ability to conform to the glass surface. The FAW Russian Side-Opening Window Glass seals are formulated to remain flexible at temperatures as low as -50°C. This flexibility ensures that the seal maintains a constant pressure against the glass, preventing freezing drafts from penetrating the cabin. A compromised seal not only makes the cabin uncomfortable but also allows moisture ingress, which can lead to mold growth and corrosion of the window frame.

The profile of the seal strip features a multi-lip design. The primary lip creates the main weather seal, while secondary lips act as baffles to block wind noise and channel water away from the opening. This drainage logic is a critical aspect of the FAW Russian Side-Opening Window Glass, ensuring that melted snow or rain does not pool in the window track where it could refreeze and jam the mechanism.

Fastening Strategy and Vibration Resistance

Securing the FAW Russian Side-Opening Window Glass to the cab structure requires a fastening system that is both secure and aesthetically unobtrusive. The assembly uses Hexagon Socket Head Cap Screw (Part No. CQ2180620F6). These bolts feature a cylindrical head with an internal hex drive, allowing for high torque application in tight spaces. The socket head design sits flush or recessed within the window frame, reducing the risk of snagging on cleaning cloths or the driver’s clothing.

Complementing these are the Cross Recessed Pan Head Screw and Washer Assembly (Part No. Q2360620). These screws include an integrated washer that distributes the clamping load, preventing damage to the softer aluminum or plastic components of the window frame. The FAW Russian Side-Opening Window Glass relies on these fasteners to maintain the compression of the seal strip. If these screws were to loosen, the window frame would pull away from the cab, breaking the seal and allowing water ingress.

The “F6” designation on the socket head screws indicates a specialized corrosion-resistant coating. This is essential for the FAW Russian Side-Opening Window Glass, which is constantly exposed to the elements. Standard black oxide bolts would rust quickly, staining the window frame and eventually seizing in the threaded holes. The corrosion-resistant coating ensures that the window assembly remains serviceable, allowing for future replacement or adjustment without the need for drilling out rusted fasteners.

Maintenance and Operational Care

Maintenance of the FAW Russian Side-Opening Window Glass is relatively simple but vital. The primary task is to keep the Left Seal Strip and Right Seal Strip clean and lubricated. Drivers should periodically wipe the seals with a silicone-based lubricant to prevent them from sticking to the glass in freezing weather. Forcing a frozen window open can tear the seal or damage the latch mechanism.

The latching mechanism of the Opening Side Window Assembly should be inspected for smooth operation. If the window becomes difficult to close or latch, check for debris in the track or misalignment of the frame. The mounting screws, particularly the Hexagon Socket Head Cap Screw, should be checked for tightness during routine service intervals. A loose frame will vibrate and eventually cause the glass to rattle or even shatter.

In the event of glass breakage, the entire Opening Side Window Assembly is typically replaced as a unit. This ensures that the glass is properly bonded to the frame and that the latch geometry is factory-set. Attempting to replace just the glass pane in the field is difficult and often results in leaks. Using genuine FAW parts for the FAW Russian Side-Opening Window Glass guarantees that the replacement unit fits perfectly into the cab aperture, restoring the vehicle’s weather-tightness immediately.

Conclusion: Ventilation with Security

The FAW Russian Side-Opening Window Glass assembly is a key component for driver comfort and safety. Comprising just 4 essential part types, it provides a controlled ventilation source that withstands the harsh Russian climate. The integration of tempered glass, arctic-grade seals, and corrosion-resistant fasteners ensures that this system remains reliable throughout the truck’s service life.

For fleet operators, maintaining the functionality of these windows is important for driver satisfaction. A well-sealed, functioning window allows for fresh air without the penalty of drafts or leaks. By prioritizing the care of the FAW Russian Side-Opening Window Glass, operators ensure that their drivers have a comfortable, adaptable workspace, ready for the challenges of the road.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.