FAW Russian Sensor Logic Assembly: The Digital Sentinel Monitoring 4 Vital Pressures for Zero-Failure Logistics

The FAW Russian Sensor Logic Assembly serves as the central nervous system for the fluid management architecture of the CA3250P66K24L1TE5Z dump truck. In the unforgiving climate of the Russian Federation, where fuel viscosity changes and air lines freeze, blind operation is not an option. This assembly aggregates data from the fuel tank and the pneumatic braking reservoirs, translating physical levels into digital alerts. By installing the FAW Russian Sensor Logic Assembly, operators gain a precise, real-time lifeline to their vehicle’s endurance and safety status, preventing the catastrophe of running dry or losing brake pressure in a whiteout.

FAW Russian Sensor Logic Assembly

| No. |

Part Number |

Part Name |

Qty |

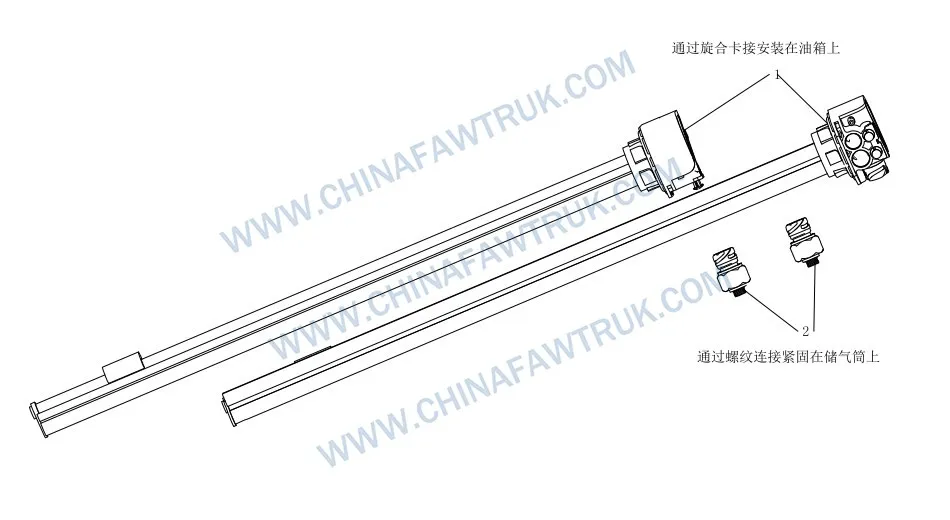

| 1 | 3806040-55R | Fuel Sensor Assembly (Sample) | 2 |

| 2 | 3757010-61B | Air Pressure Sensor Assembly | 2 |

Fuel Level Sensing: The “55R” Arctic Standard

At the heart of the FAW Russian Sensor Logic Assembly lies the Fuel Sensor Assembly (Part No. 3806040-55R). This component is engineered to overcome the specific challenges of monitoring diesel fuel in extreme cold. Standard float sensors can become sluggish as diesel waxes at low temperatures, leading to erratic needle movement on the gauge. The “55R” variant integrated into the FAW Russian Sensor Logic Assembly features a high-buoyancy float and a low-friction pivot mechanism that cuts through thickened fuel, ensuring the driver receives a steady, accurate reading of the remaining range.

The electrical interface of the fuel sensor within the FAW Russian Sensor Logic Assembly uses a thick-film ceramic resistor card. This technology is superior to wire-wound potentiometers, offering a smoother signal output that the dashboard computer can easily interpret. By minimizing signal noise, the FAW Russian Sensor Logic Assembly prevents the fuel gauge from fluctuating wildly when the truck traverses the corrugated haul roads typical of Russian mining sites. This stability is crucial for planning refueling stops in remote areas where running out of fuel is a life-threatening emergency.

Additionally, the FAW Russian Sensor Logic Assembly incorporates a low-level warning circuit directly into the sensor head. This redundancy ensures that even if the analog signal wire is damaged, the “Low Fuel” warning light will still trigger via a separate ground path. This fail-safe logic is a hallmark of FAW’s heavy-duty design philosophy, prioritizing driver awareness above all else.

Pneumatic System Monitoring Logic

The safety of a 30-ton dump truck relies entirely on its air brakes, and the FAW Russian Sensor Logic Assembly acts as the watchdog for this critical system. The Air Pressure Sensor Assembly (Part No. 3757010-61B) monitors the stored energy in the brake reservoirs. Unlike mechanical switches that only indicate a low-pressure state, these advanced sensors provide a linear voltage signal to the FAW Russian Sensor Logic Assembly, allowing the on-board computer to display precise barometric pressure readings for both the front and rear brake circuits.

The “61B” sensor specification indicates a hermetically sealed, piezo-resistive design. In the Russian winter, condensation in the air lines can freeze, potentially destroying delicate sensor diaphragms. The FAW Russian Sensor Logic Assembly utilizes sensors with a burst pressure rating far exceeding the system’s 10-bar operating limit, ensuring resilience against pressure spikes caused by frozen unloader valves. This ruggedness ensures that the FAW Russian Sensor Logic Assembly continues to report accurate data even when the pneumatic system is under extreme environmental stress.

Furthermore, the FAW Russian Sensor Logic Assembly performs a continuous “rationality check” on the air pressure data. If the sensor reports zero pressure while the compressor is running and the vehicle is moving, the logic identifies a sensor fault rather than a system failure, preventing unnecessary panic stops. This intelligent processing capability distinguishes the genuine FAW Russian Sensor Logic Assembly from simple aftermarket replacements.

Integration and Environmental Protection

The components of the FAW Russian Sensor Logic Assembly are strategically located in high-exposure areas: inside the fuel tank and on the chassis frame rails. To survive, they feature heavy-duty environmental hardening. The external connectors on the Air Pressure Sensor Assembly use automotive-grade weather packs with triple-ribbed silicone seals. This prevents salt brine and road slush from wicking into the FAW Russian Sensor Logic Assembly harness, which is the leading cause of “green wire” corrosion and signal loss in commercial vehicles.

The fuel sensor flange is sealed with a nitrile rubber gasket that remains flexible at -50°C, preventing diesel leakage and fume escape. The FAW Russian Sensor Logic Assembly mounting points are reinforced to withstand the hydraulic hammer effect of fuel sloshing during sudden stops. By securing the sensor rigidly, FAW prevents fatigue cracking of the mounting plate, ensuring the FAW Russian Sensor Logic Assembly maintains a vapor-tight seal for the life of the vehicle.

Signal integrity is maintained by the use of twisted-pair wiring for the sensor feeds within the main harness. This configuration cancels out electromagnetic interference from the alternator and injectors, ensuring that the FAW Russian Sensor Logic Assembly delivers a pure, uncorrupted signal to the instrument cluster. This attention to electrical hygiene is critical for modern, ECU-controlled vehicles where voltage fluctuations can trigger cascading fault codes.

Diagnostics and Calibration

Diagnosing issues with the FAW Russian Sensor Logic Assembly is straightforward due to its linear output characteristics. A technician can use a multimeter to measure the resistance across the fuel sensor pins; a value outside the specified range (e.g., 10-180 ohms) indicates a failed unit. Similarly, the FAW Russian Sensor Logic Assembly air sensors can be back-probed to verify that the output voltage corresponds to the pressure reading on a mechanical workshop gauge. This ease of diagnostics reduces downtime in the field.

Calibration is generally not required for the FAW Russian Sensor Logic Assembly as the components are factory-matched to the instrument cluster. However, when replacing a sensor, it is vital to ensure the correct part number is used. A “55R” fuel sensor has a specific swing arm length tailored to the Russian-spec high-capacity tank. Installing a standard sensor would result in the FAW Russian Sensor Logic Assembly reporting an empty tank when 100 liters remain, potentially stranding the driver.

Fleet maintenance schedules should include a visual inspection of the sensor wiring and connector security. The FAW Russian Sensor Logic Assembly is robust, but physical damage from ice impact or chafing can compromise the system. Proactive checks ensure that the driver always has accurate data on the vital fluids that keep the truck moving and stopping safely.

Conclusion: Trustworthy Data in a Hostile World

The FAW Russian Sensor Logic Assembly is the unsung hero of the driver’s dashboard, converting invisible pressures and levels into actionable information. By integrating high-precision fuel and air sensors, it provides the situational awareness necessary for safe operation in the Russian Arctic. The 4 components listed form a cohesive data acquisition network that is built to last.

For fleet managers, the reliability of the FAW Russian Sensor Logic Assembly translates directly to operational efficiency. Accurate fuel data allows for optimized routing, while reliable air pressure monitoring ensures safety compliance. By maintaining these sensors with genuine FAW parts, operators ensure that their fleet runs on facts, not guesswork.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.