FAW Russian Rear Enclosure Panel: Superior 4-Component System for Flawless Thermal and Acoustic Isolation

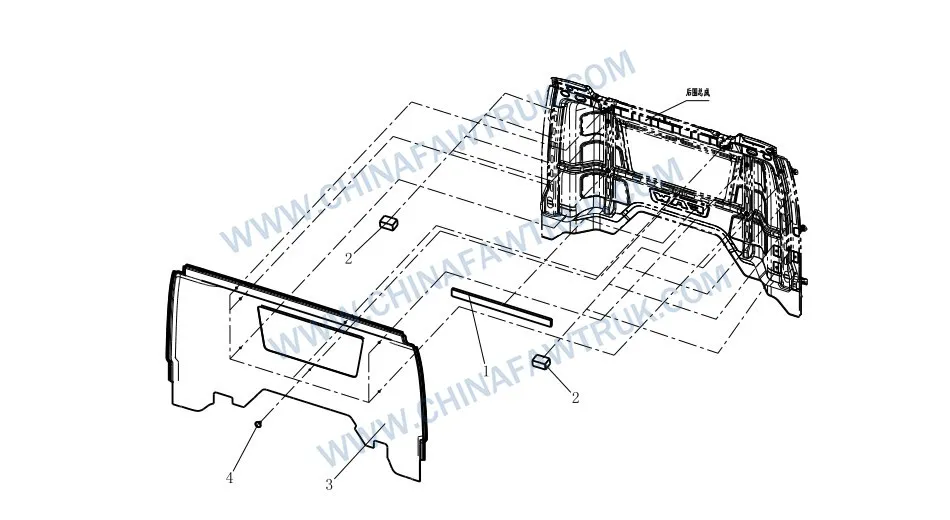

The FAW Russian Rear Enclosure Panel assembly serves as the definitive structural and thermal barrier for the rear wall of the CA3250P66K24L1TE5Z dump truck cabin. Engineered specifically for the extreme latitudes of the Russian Federation, this system integrates a heavy-duty outer shell with precision spacing elements to isolate the driver from the harsh exterior environment. By establishing a hermetic seal against arctic winds and mining dust, the FAW Russian Rear Enclosure Panel ensures that the cabin remains a secure, quiet, and temperature-controlled command center, critical for maintaining operator alertness and safety during extended shifts.

FAW Russian Rear Enclosure Panel

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5602061-B27 | Spacer Block A for Rear Enclosure Panel | 1 |

| 2 | 5702028-A02 | Spacer Block – Roof Center Guard | 8 |

| 3 | 5602011-B35 | Rear Enclosure Panel | 1 |

| 4 | 5702028-A01 | Buckle – Roof Cover Guard | 7 |

FAW Russian Rear Enclosure Panel Assembly2 (with Independent Heater)

| No. |

Part Number |

Part Name |

Qty |

| 1 | 5602061-B27 | Spacer Block A for Rear Enclosure Panel | 1 |

| 2 | 5702028-A02 | Spacer Block – Roof Center Guard | 8 |

| 3 | 5602011AB96 | Rear Enclosure Panel | 1 |

| 4 | 5702028-A01 | Buckle – Roof Cover Guard | 7 |

Core Protection Architecture

The centerpiece of the FAW Russian Rear Enclosure Panel system is the Rear Enclosure Panel itself (Part No. 5602011-B35). This component is not merely a cosmetic cover; it is a structural skin designed to protect the rear face of the cabin from the physical and environmental onslaught typical of mining sites. Manufactured from high-impact composite materials or corrosion-resistant stamped steel, this panel acts as the first line of defense against rockfall from the dump body and the abrasive slurry kicked up by the rear tires. In the context of the FAW Russian Rear Enclosure Panel, durability is paramount, as any breach in this shield exposes the cabin’s insulation layers to moisture saturation.

The geometric design of the Rear Enclosure Panel is engineered to deflect wind and debris away from critical cab seals. Its contours align perfectly with the roof and side fairings, creating a seamless aerodynamic profile that reduces drag and wind noise. For the FAW Russian Rear Enclosure Panel, this seamless integration is vital for maintaining the thermal envelope of the vehicle. By minimizing gaps where cold air could infiltrate, the panel helps the HVAC system maintain a comfortable interior temperature without excessive fuel consumption, a crucial factor in the sub-zero winters of the Russian North.

Furthermore, the Rear Enclosure Panel serves as a mounting substrate for additional accessories such as work lights or air line connections. Its rigid structure supports these loads without flexing or vibrating, ensuring that auxiliary equipment remains secure. The surface finish of the FAW Russian Rear Enclosure Panel is treated to resist UV degradation and chemical attack from road salts, maintaining the vehicle’s professional appearance and structural integrity over years of service in harsh conditions.

Precision Spacing and Vibration Isolation

The effectiveness of the FAW Russian Rear Enclosure Panel relies heavily on its isolation from the main cab structure. This is achieved through the use of specialized spacing components, specifically the Spacer Block A for Rear Enclosure Panel (Part No. 5602061-B27) and the multiple units of Spacer Block – Roof Center Guard (Part No. 5702028-A02). These spacers create a calculated gap between the exterior panel and the inner cabin wall. In the FAW Russian Rear Enclosure Panel system, this gap serves as a thermal break, preventing conductive heat loss from the warm interior to the freezing exterior metal.

These spacer blocks are molded from dense, vibration-damping rubber or polyurethane. They absorb the high-frequency tremors generated by the diesel engine and the low-frequency shocks from rough haul roads. Without these components, the FAW Russian Rear Enclosure Panel would vibrate directly against the cab frame, creating unbearable noise for the driver and leading to fatigue cracks in the panel mounting points. The Spacer Block – Roof Center Guard plays a dual role by also aligning the upper edge of the panel with the roof fairing, ensuring a consistent aerodynamic transition.

Additionally, the spacing provided by these blocks allows for drainage and airflow behind the panel. This ventilation prevents moisture from becoming trapped between the Rear Enclosure Panel and the cab wall, which is a primary cause of hidden rust. By facilitating the evaporation of condensation, the FAW Russian Rear Enclosure Panel spacing system actively protects the structural longevity of the vehicle’s body-in-white, demonstrating a thoughtful approach to corrosion prevention in wet and snowy climates.

Secure Retention and Assembly Logic

The retention of the FAW Russian Rear Enclosure Panel is managed by the Buckle – Roof Cover Guard (Part No. 5702028-A01). These specialized fasteners are designed for blind installation, allowing the panel to be snapped securely into place without requiring access to the back side of the mounting surface. In the assembly of the FAW Russian Rear Enclosure Panel, seven of these buckles are strategically distributed around the perimeter to ensure uniform clamping pressure. This distribution prevents the panel from warping or bowing under thermal expansion, maintaining a flush fit with the adjacent bodywork.

The material of the Buckle – Roof Cover Guard is engineered to retain its elasticity in extreme cold. Standard plastic clips often become brittle and snap when subjected to vibration at -40°C. The buckles used in the FAW Russian Rear Enclosure Panel are formulated from a cold-resistant polymer that maintains a strong grip on the panel mounting tabs regardless of the temperature. This reliability is essential for preventing the panel from detaching at highway speeds, which would pose a significant safety hazard to other road users.

The buckle design also facilitates serviceability. In the event of body damage or the need to access wiring routed behind the panel, the FAW Russian Rear Enclosure Panel can be removed by disengaging these clips. The “snap-fit” logic reduces assembly time on the production line and simplifies repair procedures in the field. Fleet mechanics can replace a damaged Rear Enclosure Panel quickly, minimizing vehicle downtime and ensuring the truck returns to operation with its protective shell fully restored.

Maintenance and Integrity Checks

Regular inspection of the FAW Russian Rear Enclosure Panel is a key aspect of preventative maintenance. Fleet operators should visually check the panel for stress cracks, particularly around the mounting points where the Buckle – Roof Cover Guard engages. A loose or rattling panel indicates that one or more clips may have failed or that the Spacer Block A for Rear Enclosure Panel has compressed excessively. Immediate replacement of compromised fasteners ensures that the FAW Russian Rear Enclosure Panel remains secure and functional.

It is also important to inspect the gaps around the Rear Enclosure Panel for debris accumulation. In mining environments, mud and small rocks can become wedged behind the panel, bridging the gap created by the Spacer Block – Roof Center Guard. This debris can abrade the paint and trap moisture, negating the corrosion-protection benefits of the design. Periodically flushing the area behind the FAW Russian Rear Enclosure Panel with a high-pressure washer helps to maintain the integrity of the cab’s rear wall.

When replacing components, using genuine FAW parts is non-negotiable. The Rear Enclosure Panel and its associated spacers and buckles are designed as a matched set. Generic clips may not provide the correct clamping force or standoff distance, leading to wind noise, water leaks, or panel loss. The genuine FAW Russian Rear Enclosure Panel components guarantee a factory-perfect fit, restoring the vehicle’s original aerodynamic and protective specifications.

Conclusion: The Guardian of the Rear

The FAW Russian Rear Enclosure Panel assembly is a vital component in the overall durability strategy of the CA3250 dump truck. Although comprising only 4 part numbers, this system plays a disproportionately large role in protecting the cabin structure and maintaining driver comfort. The combination of the robust Rear Enclosure Panel, precise spacers, and resilient buckles creates a shield capable of withstanding the rigors of the Russian heavy transport sector.

For fleet managers, the condition of the FAW Russian Rear Enclosure Panel serves as a barometer for the vehicle’s overall body health. A well-maintained rear enclosure prevents insidious corrosion and contributes to fuel efficiency. By prioritizing the inspection and upkeep of this assembly, operators invest in the long-term reliability and resale value of their fleet assets.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.