FAW Russian Front Fog Lamp Logic: Integrating 10 Precision Units for Penetrating Arctic Whiteouts

The FAW Russian Front Fog Lamp assembly represents the tactical lighting tier of the CA3250P66K24L1TE5Z dump truck’s visibility system. Specifically engineered for the Russian North, this dual-function logic assembly combines a low-mounted fog beam with a high-visibility turn signal. In conditions where blizzards or dense ice fog render standard headlights ineffective due to back-glare, the FAW Russian Front Fog Lamp cuts underneath the visual obstruction, illuminating the road surface directly in front of the wheels. This guide examines the optical engineering, cold-weather materials, and mounting precision that make this assembly indispensable for winter safety.

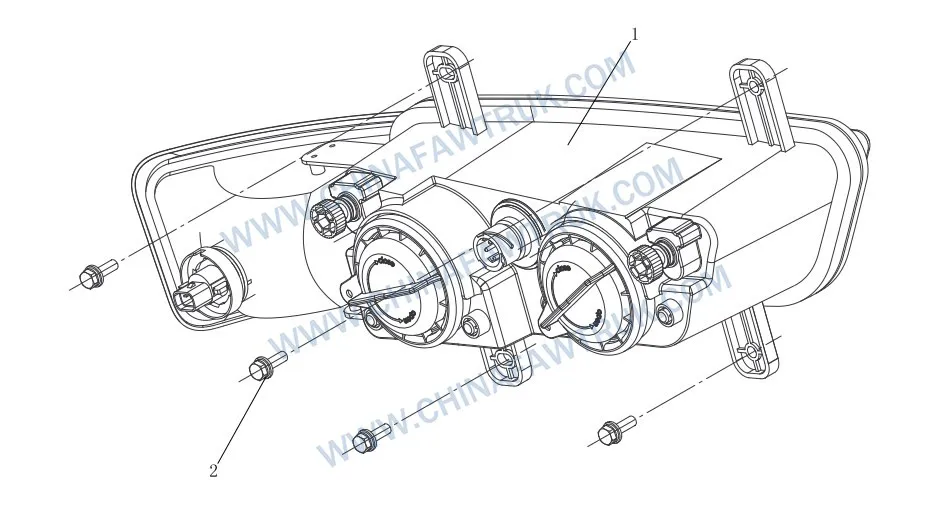

FAW Russian Front Fog Lamp

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3732015-91W-C00 | Left Front Fog Lamp & Front Turn Signal Assembly | 1 |

| 1 | 3732020-91W-C00 | Right Front Fog Lamp & Front Turn Signal Assembly | 1 |

| 2 | CQ1460620 | Combination Bolt | 8 |

Dual-Function Optics for Adverse Weather

The FAW Russian Front Fog Lamp is distinguished by its split-optic design. The lower section houses the fog beam, which utilizes a fluted lens pattern to spread light wide and flat. This geometry is crucial for Arctic driving; a standard conical beam would reflect off falling snowflakes, blinding the driver with a “wall of white.” The FAW Russian Front Fog Lamp projects its beam parallel to the ground, highlighting the road texture and lane markings without illuminating the precipitation above the driver’s eye level. This capability is essential for maintaining safe speeds during the frequent blizzards of the Russian winter.

The upper section of the Left Front Fog Lamp & Front Turn Signal Assembly (Part No. 3732015-91W-C00) contains the directional indicator. In the J6P design, this turn signal is positioned lower than the main headlights but wider than the grille, ensuring it remains visible to smaller vehicles that might be positioned in the truck’s blind spots. The FAW Russian Front Fog Lamp integrates an amber reflector that amplifies the signal light, ensuring that the driver’s turning intent is communicated clearly even in bright sunlight reflecting off the snowpack.

The light source within the FAW Russian Front Fog Lamp is typically a high-output halogen bulb (H3 or similar). While LEDs are efficient, the heat generated by a halogen bulb is a functional asset in this specific application. It warms the front lens, preventing the buildup of ice and slush that would otherwise occlude the light. This passive de-icing feature is a hallmark of the FAW Russian Front Fog Lamp design, ensuring consistent performance without the need for complex electrical heating elements that could drain the battery.

Impact Resistance and Sealing Technology

Mounted low on the bumper, the FAW Russian Front Fog Lamp is in the direct line of fire for road debris. To survive this, the housing is molded from a toughened Polypropylene/EPDM composite that retains flexibility at -50°C. Rigid plastics would shatter upon impact with frozen soil or rocks. The lens of the FAW Russian Front Fog Lamp is crafted from thick-walled polycarbonate, treated with a hard-coat layer to resist sandblasting. This ensures that the optical clarity is maintained even after thousands of kilometers on unpaved mining roads.

Water ingress is the primary cause of fog lamp failure. The Right Front Fog Lamp & Front Turn Signal Assembly (Part No. 3732020-91W-C00) features a hermetic seal between the lens and housing, bonded with an industrial-grade urethane adhesive. The bulb access ports on the rear are sealed with high-compression rubber caps or twist-lock covers fitted with O-rings. In the FAW Russian Front Fog Lamp, these seals are formulated to resist the corrosive brine used for de-icing, which can degrade lesser rubber compounds and lead to leaks.

Furthermore, the FAW Russian Front Fog Lamp incorporates a sophisticated venting system. As the lamp heats up during use, internal pressure builds; when it cools rapidly (e.g., during a river crossing or truck wash), a vacuum forms. Without a vent, this vacuum would suck water past the seals. The assembly uses a microporous membrane that allows air exchange to equalize pressure but blocks water molecules and dust particles. This technology keeps the interior of the FAW Russian Front Fog Lamp dry and free of condensation fogging.

Mounting Logic: The Combination Bolt

The securement of the FAW Russian Front Fog Lamp relies on 8 units of the Combination Bolt (Part No. CQ1460620). This fastener is critical to the assembly’s longevity. A combination bolt integrates a hex head with a captive flat washer and a spring washer. In the high-vibration environment of a diesel dump truck, this integrated design prevents the washer from being lost during maintenance and ensures consistent clamping force. The flat washer distributes the load across the plastic mounting tabs of the FAW Russian Front Fog Lamp, preventing stress cracks.

The mounting points on the bumper are often slotted to allow for beam aiming. Proper alignment of the FAW Russian Front Fog Lamp is essential; if aimed too high, it blinds oncoming drivers and renders the fog-cutting capability useless. If aimed too low, the effective visual range is reduced. The Combination Bolt allows mechanics to loosen the unit slightly, adjust the angle, and then lock it down securely. The zinc-flake coating on these bolts prevents seizing, ensuring that the FAW Russian Front Fog Lamp can be easily adjusted or replaced even after years of exposure to road salt.

Vibration dampening is inherent in the mounting design. The plastic tabs of the FAW Russian Front Fog Lamp have a calculated degree of flex, acting as a shock absorber for the bulb filaments. Rigidly mounting a lamp to a steel bumper transfers 100% of the chassis shock to the bulb, leading to premature failure. By using the specific torque settings on the Combination Bolt, technicians ensure that the assembly is secure yet capable of absorbing the kinetic energy of rough terrain without self-destructing.

Electrical Integrity and Maintenance

The FAW Russian Front Fog Lamp connects to the chassis harness via a heavy-duty, waterproof connector. Unlike standard automotive plugs, this connector features a secondary lock to prevent disconnection under vibration. The terminals are plated to resist fretting corrosion, a common issue where micro-movements wear away the contact surface. Maintaining a low-resistance connection is vital for the FAW Russian Front Fog Lamp, as voltage drops directly reduce the lumen output of the halogen bulbs, diminishing their effectiveness in fog.

Routine maintenance involves inspecting the lens for cracks and checking the operation of both the fog and turn signal filaments. A cracked lens on a FAW Russian Front Fog Lamp will allow water to enter, blowing the hot bulb instantly. Fleet operators should also check the aim of the lamps as part of the periodic service schedule. Misaligned lamps are a safety hazard to everyone on the road.

When replacing a bulb, it is imperative not to touch the glass envelope with bare fingers, as skin oils can cause hot spots and bulb failure. If the entire FAW Russian Front Fog Lamp assembly is damaged, it should be replaced with a genuine unit. Aftermarket copies often lack the correct internal venting and cold-weather plastic formulations, leading to rapid fogging and brittleness in the Russian winter. Using genuine parts ensures that the visibility and safety of the truck are never compromised.

Conclusion: Cutting Through the Grey

The FAW Russian Front Fog Lamp assembly is a specialized tool for visibility in the most challenging conditions. Comprising just 10 key elements—two main assemblies and eight specialized bolts—it provides the optical precision required to navigate Arctic whiteouts and dense fog safely. Its robust construction protects the light source, while its thermal characteristics keep the lens clear of ice.

For fleet maintenance teams, the FAW Russian Front Fog Lamp is a critical safety item. Ensuring that these lamps are functional, properly aimed, and securely mounted with the correct Combination Bolt hardware is essential for safe operations. By maintaining this system, operators give their drivers the best possible chance of avoiding hazards in the low-visibility environment of the Russian heavy transport sector.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.