FAW Russian Door-Open Alarm Light Logic: Safeguarding 5 Vital Elements for Fail-Safe Cabin Security

The FAW Russian Door-Open Alarm Light assembly serves as the critical safety annunciator for the CA3250P66K24L1TE5Z dump truck operator. In the extreme environments of the Russian Federation, where cabin integrity is essential for thermal management and dust exclusion, knowing the precise status of the door latches is vital. This logic assembly does not merely illuminate; the FAW Russian Door-Open Alarm Light acts as a primary warning system, ensuring that the driver is instantly alerted to any breach in the cabin’s secure perimeter before the vehicle enters the hazardous conditions of a mining haul road.

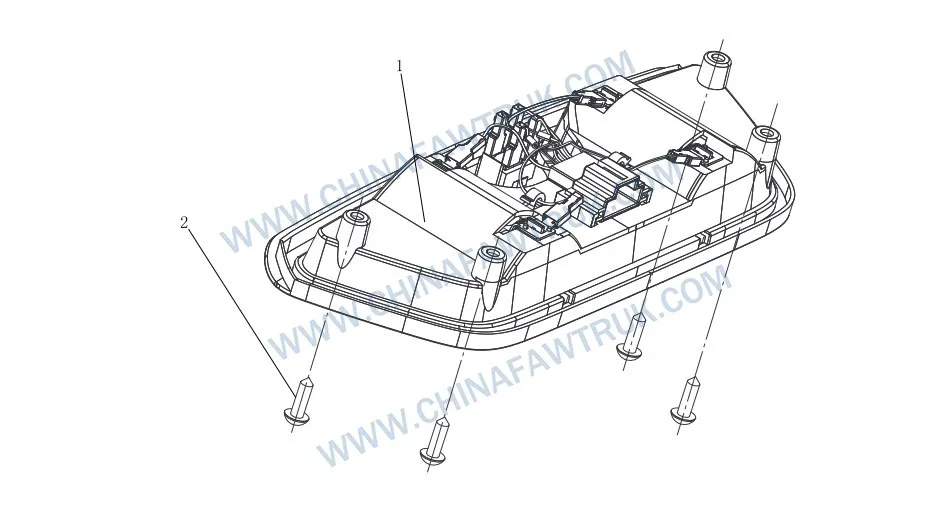

FAW Russian Door-Open Alarm Light

| No. |

Part Number |

Part Name |

Qty |

| 1 | 3714010-91W-C00 | Door Open Alarm Light Assembly | 1 |

| 2 | CQ2714816 | Cross Recessed Pan Head Tapping Screw | 4 |

Critical Alert Logic in Arctic Operations

The primary function of the FAW Russian Door-Open Alarm Light is to provide immediate, unambiguous visual feedback to the driver regarding the status of the cabin entry points. In the context of a J6P dump truck operating in the Russian Arctic, a door that is not fully latched poses severe risks. Firstly, it compromises the structural integrity of the cab during chassis articulation on rough terrain. Secondly, and perhaps more critically, an unsealed door allows the rapid loss of cabin heat and the ingress of freezing air, snow, and exhaust fumes. The FAW Russian Door-Open Alarm Light is the first line of defense against these environmental hazards, ensuring that the operator creates a sealed, safe microclimate before the vehicle moves.

The Door Open Alarm Light Assembly (Part No. 3714010-91W-C00) is engineered with a high-luminescence profile. In the bright glare of sunlight reflecting off snow, standard dashboard indicators can be washed out and missed. However, the specific optical design of the FAW Russian Door-Open Alarm Light utilizes a high-contrast red lens and a concentrated beam pattern to ensure visibility even in high-ambient light conditions. Conversely, during the long polar nights, the light is calibrated to be attention-grabbing without destroying the driver’s night vision, a balance critical for safety during 24-hour mining operations where fatigue is a constant factor.

The logic driving the FAW Russian Door-Open Alarm Light is integrated with the door latch microswitches. When the latch pawl is not fully engaged in the secondary lock position, the circuit remains closed, illuminating the assembly. This simple yet robust logic ensures that a “half-latched” door—a common occurrence when ice builds up on the door seals—triggers the alarm. By providing this positive confirmation, the FAW Russian Door-Open Alarm Light prevents the dangerous scenario of a door popping open unexpectedly while the truck is navigating a steep quarry switchback, protecting both the driver and the expensive cabin instrumentation from exposure.

Material Science: Polymer Resilience

The construction of the FAW Russian Door-Open Alarm Light reflects the rigorous demands of the “50A” cold-zone specification. Standard interior plastics can become brittle and shatter when subjected to the vibration of a diesel engine at -40°C. The housing of the Door Open Alarm Light Assembly is molded from an impact-modified ABS or Polypropylene blend specifically formulated for ductility at cryogenic temperatures. This ensures that the mounting tabs do not snap off during installation or when the truck hits a pothole, preserving the physical integrity of the FAW Russian Door-Open Alarm Light throughout the vehicle’s service life.

The lens material of the FAW Russian Door-Open Alarm Light is equally specialized. It employs a UV-stabilized polycarbonate that resists fading and clouding. In high-altitude mining environments, UV radiation is intense, and standard plastics can degrade rapidly, turning opaque and reducing the light’s visibility. The high-grade optics of this assembly ensure that the red warning signal remains distinct and bright for years. Furthermore, the lens is sealed to the housing using a sonic welding process or a high-grade adhesive that prevents the ingress of moisture. Cabin condensation is a major issue in cold climates; a non-sealed lamp would quickly fog up or corrode internally, leading to failure of the FAW Russian Door-Open Alarm Light.

The internal illumination source of the FAW Russian Door-Open Alarm Light typically utilizes LED technology in modern J6P iterations. LEDs offer distinct advantages in the Arctic: they have an instant-on response time unaffected by cold, unlike incandescent filaments which can be brittle and slow to reach full brightness. Moreover, the low current draw of an LED-based FAW Russian Door-Open Alarm Light places minimal load on the electrical system, which is crucial when the batteries are already under heavy strain from cold cranking and heating systems. The solid-state nature of LEDs also makes them impervious to the shock and vibration defined by the dump truck’s duty cycle.

Mounting Integrity and Fastener Logic

Securing the FAW Russian Door-Open Alarm Light to the interior trim panel requires a fastening strategy that balances retention with serviceability. The assembly utilizes four Cross Recessed Pan Head Tapping Screw units (Part No. CQ2714816). The choice of a self-tapping screw is deliberate. These fasteners bite directly into the polymer substrate of the dashboard or door pillar, creating a tight, vibration-resistant interference fit. In the context of the FAW Russian Door-Open Alarm Light, this securement is vital to prevent the assembly from rattling or buzzing, which would contribute to operator fatigue.

The Cross Recessed Pan Head Tapping Screw features a wide head profile that distributes the clamping load over the plastic mounting flange of the light assembly. This distribution prevents stress risers that could lead to cracking around the bolt holes, a common failure mode in cold plastics. The screws are treated with a zinc-flake or black oxide coating to resist corrosion. Even inside the cab, humidity levels can be high due to melting snow on boots and clothing. Corroded screws would make replacing a faulty FAW Russian Door-Open Alarm Light difficult, potentially damaging the surrounding trim panels during removal.

Installation of the FAW Russian Door-Open Alarm Light requires precise torque control on these tapping screws. Over-tightening can strip the plastic threads in the mounting base, rendering the mount useless and requiring complex repairs to the dashboard structure. Under-tightening allows the light to vibrate, which can wear through the wiring insulation or cause the connector to fret. The maintenance protocol for the FAW Russian Door-Open Alarm Light emphasizes “snug-tight” installation to maintain the delicate balance between retention and material preservation.

Electrical Integration and Diagnostics

The electrical interface of the FAW Russian Door-Open Alarm Light is designed for robustness. The pigtail connector features a locking tab to prevent separation under vibration. The terminals are often plated to resist oxidation, ensuring a low-resistance connection that maintains the light’s brightness over time. In the FAW Russian Door-Open Alarm Light circuit, the ground path is typically switched by the door jamb sensor. This “switched ground” logic is safer, as it minimizes the amount of live wiring running through the door hinge area, reducing the risk of short circuits if the wire loom is damaged by constant flexing.

Diagnosing issues with the FAW Russian Door-Open Alarm Light is a straightforward but essential task. If the light fails to illuminate when the door is open, the fault could lie in the bulb/LED, the fuse, or the door switch. However, if the light stays on permanently, it often indicates a frozen or corroded door switch that is stuck in the closed position—a frequent occurrence in Russian winters. Fleet mechanics must understand that the FAW Russian Door-Open Alarm Light is merely the indicator; the root cause often lies in the environmental exposure of the peripheral sensors.

The wiring harness feeding the FAW Russian Door-Open Alarm Light uses cold-resistant insulation, typically cross-linked polyethylene (XLPE), which remains flexible at -50°C. Standard PVC insulation can crack in these temperatures, leading to copper exposure and short circuits. Ensuring the integrity of the wiring leading to the Door Open Alarm Light Assembly is as important as the component itself. A functional alarm light is a mandatory check before any shift, as it verifies the readiness of the cabin’s passive safety systems.

Conclusion: A Vital Signal in the Cold

The FAW Russian Door-Open Alarm Light assembly, though small in size, plays an outsized role in the operational safety of the CA3250 dump truck. Comprising just 5 essential components—the main assembly and its four securing screws—this unit stands as the guardian of cabin integrity. Its design reflects a deep understanding of the Russian Arctic environment, prioritizing visibility, material durability, and reliable electrical performance.

For fleet maintenance teams, the FAW Russian Door-Open Alarm Light should not be treated as a trivial accessory. It is a safety-critical indicator. Ensuring that the Door Open Alarm Light Assembly is functioning and securely mounted with the correct Cross Recessed Pan Head Tapping Screw fasteners guarantees that drivers receive the timely warnings they need to keep the cold out and the safety in. By maintaining this simple system, operators contribute to the overall reliability and safety culture of the heavy transport fleet.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.