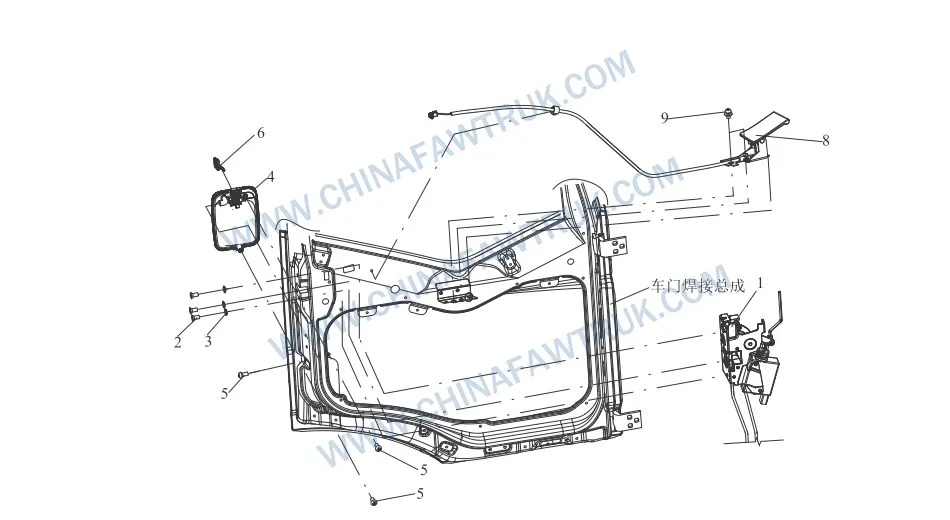

FAW Russian Door Lock Mechanism: 9 Robust Components Ensuring Secure and Reliable Cabin Access

The FAW Russian Door Lock Mechanism assembly is the central security system for the CA3250P66K24L1TE5Z dump truck. In the demanding environment of the Russian Federation, a door lock must do more than simply latch; it must operate reliably in freezing temperatures, resist the ingress of corrosive road salts, and withstand the constant vibration of heavy-duty operation. This assembly integrates manual and electric actuators, robust outer handles, and ergonomic inner releases into a cohesive unit that guarantees driver safety and vehicle security.

FAW Russian Door Lock Mechanism

| No. |

Part Number |

Part Name |

Qty |

| 1 | 6105025-A01 | Left Front Door Lock Assembly | 1 |

| 6105025AA01 | Left Front Door Electric Lock Body Assembly | 1 |

| 6105030-A01 | Right Front Door Lock Assembly | 1 |

| 6105030AA01 | Right Front Door Electric Lock Body Assembly | 1 |

| 2 | Q2540612 | Cross Recessed Countersunk Head Screw | 6 |

| 3 | Q41406 | Conical Toothed Lock Washer | 6 |

| 4 | 6105105-A01 | Left Front Door Outer Handle Assembly | 1 |

| 6105110-A01 | Right Front Door Outer Handle Assembly (See 6105105-A01) | 1 |

| 5 | Q2360612 | Cross Recessed Pan Head Screw and Washer Assembly | 6 |

| 6 | 6105190-A01 | Key Assembly | 2 |

| 7 | 6105185-B27-C00 | Remote Control Key Mechanical Assembly | 1 |

| 8 | 6105075-B27-C00 | Left Front Door Inner Handle Assembly | 1 |

| 6105080-B27-C00 | Right Front Door Inner Handle Assembly (See 6105075-B27-C00) | 1 |

| 9 | Q2360612 | Cross Recessed Pan Head Screw and Washer Assembly | 4 |

Robust Actuation and Locking Logic

The core of the FAW Russian Door Lock Mechanism is the Left Front Door Lock Assembly (Part No. 6105025-A01) and its powered variant, the Left Front Door Electric Lock Body Assembly (Part No. 6105025AA01). These robust units house the latch mechanism that grips the striker pin, holding the door closed against the torsional forces of the chassis. In the Russian Arctic, where temperatures can drop to -50°C, the grease and internal springs of these locks are formulated to resist thickening and freezing. This ensures that the door latch engages positively every time, preventing the dangerous situation of a door popping open while driving on rough mining roads.

The Right Front Door Lock Assembly (Part No. 6105030-A01) mirrors this robust construction. The “Electric Lock Body” variants integrate a high-torque actuator for the central locking system. This actuator is sealed against moisture ingress, a critical feature for vehicles operating in wet and slushy conditions. The FAW Russian Door Lock Mechanism logic ensures that the central locking signal is transmitted reliably, securing both doors simultaneously and protecting the valuable contents of the cab.

Structural integrity is maintained by the use of high-strength steel for the latch claw and catch. The interface between the lock and the striker is designed to be self-aligning, compensating for minor door sag over time. This design feature reduces wear on the mechanism and ensures that the door requires minimal effort to close securely, a small but significant comfort factor for drivers who enter and exit the cab dozens of times a day.

Ergonomic Handles for Heavy-Duty Use

The driver’s interaction with the FAW Russian Door Lock Mechanism begins with the Left Front Door Outer Handle Assembly (Part No. 6105105-A01). This handle is designed with a large, accessible grip that accommodates heavy winter gloves. Its robust pivot mechanism is engineered to break the seal of a frozen door without snapping, a common failure point in lesser vehicles. The material is impact-resistant polymer that withstands the brutality of extreme cold without becoming brittle.

Inside the cabin, the Left Front Door Inner Handle Assembly (Part No. 6105075-B27-C00) provides a smooth, low-effort release. The “B27-C00” specification indicates a finish and material blend optimized for the Russian market’s cold-zone requirements. This inner handle connects to the lock body via a rod or cable system that is routed to avoid binding. The ergonomic design ensures that the door can be opened quickly in an emergency, adhering to strict safety standards.

The Right Front Door Outer Handle Assembly (Part No. 6105110-A01) and inner handle counterpart ensure symmetrical functionality for the passenger side. Both inner and outer handles are designed to be easily serviceable. If a handle is damaged by impact, it can be replaced without replacing the entire lock mechanism, reducing maintenance costs for fleet operators.

Security Interface and Key Systems

Security is paramount, and the FAW Russian Door Lock Mechanism includes a comprehensive key system comprising the Key Assembly (Part No. 6105190-A01) and the Remote Control Key Mechanical Assembly (Part No. 6105185-B27-C00). The lock cylinders are designed with weather shutters to prevent water and dirt from entering the keyway. In freezing conditions, moisture inside the lock cylinder can freeze, locking the driver out. The FAW design minimizes this risk, ensuring the key can be inserted and turned even in icy weather.

The remote control key adds a layer of convenience and safety, allowing the driver to unlock the cab from a distance or while approaching with tools in hand. The transponder logic within the Remote Control Key Mechanical Assembly integrates with the vehicle’s immobilizer system, providing robust anti-theft protection. This integration ensures that the FAW Russian Door Lock Mechanism is not just a physical barrier but a digital one as well.

For fleet management, the key system can be keyed-alike or individual, depending on the operator’s preference. The durability of the key blades and the tumbler mechanism is tested to withstand thousands of cycles, ensuring that the primary method of vehicle access remains reliable throughout the truck’s service life.

Fastening Strategy and Installation

The security of the lock mechanism depends heavily on its fasteners. The assembly uses Cross Recessed Countersunk Head Screw (Part No. Q2540612) to mount the lock body to the door edge. The countersunk head ensures a flush fit that does not interfere with the door seal or the B-pillar striker. To prevent these screws from vibrating loose, Conical Toothed Lock Washer (Part No. Q41406) units are employed. These washers bite into the metal, providing a high-friction mechanical lock that resists the constant shaking of the dump truck chassis.

For the handle assemblies, Cross Recessed Pan Head Screw and Washer Assembly (Part No. Q2360612) fasteners are used. The integrated washer distributes the clamping load over the plastic mounting tabs of the handles, preventing stress cracks. The use of corrosion-resistant coatings on all fasteners within the FAW Russian Door Lock Mechanism ensures that they can be removed for service even after years of exposure to road salt and moisture.

Proper alignment during installation is critical. The lock body has slotted holes to allow for fine adjustment of the latch position. Correct adjustment ensures that the door closes with a solid “thunk” and seals tightly against the weatherstrip without requiring excessive force. Regular lubrication of the latch mechanism and inspection of the fasteners are key maintenance tasks that prolong the life of the FAW Russian Door Lock Mechanism.

Conclusion: Secure, Reliable, Durable

The FAW Russian Door Lock Mechanism assembly is a sophisticated system that balances physical security with operational convenience. Comprising 9 distinct components, from the high-torque electric actuators to the weather-resistant outer handles, it is built to withstand the rigors of the Russian environment. Its design ensures that the driver can always access the safety of the cabin.

For fleet operators, the reliability of the door locks is a non-negotiable aspect of vehicle readiness. A frozen or broken lock can strand a driver or leave a vehicle vulnerable. By investing in the maintenance of the FAW Russian Door Lock Mechanism using genuine parts and proper lubricants, operators protect their assets and their personnel, ensuring uninterrupted operations in even the harshest conditions.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.