FAW Russian Central-Bridge Drive Shaft: Engineering 10 Strategic Links for Seamless Multi-Axle Propulsion

The FAW Russian Central-Bridge Drive Shaft assembly is the kinetic backbone connecting the transfer case to the first rear drive axle (the middle axle) of the CA3250P66K24L1TE5Z dump truck. In the 6×6 configuration favored by Russian mining operations, this driveshaft must endure not only the high torque output of the engine but also the severe angular articulation of the chassis. Engineered to operate flawlessly in temperatures as low as -40°C, the FAW Russian Central-Bridge Drive Shaft ensures that power is transmitted without vibration or hysteresis. This guide deconstructs the 10 essential components, from the spline yokes to the dynamic balance weights, that define its heavy-duty performance.

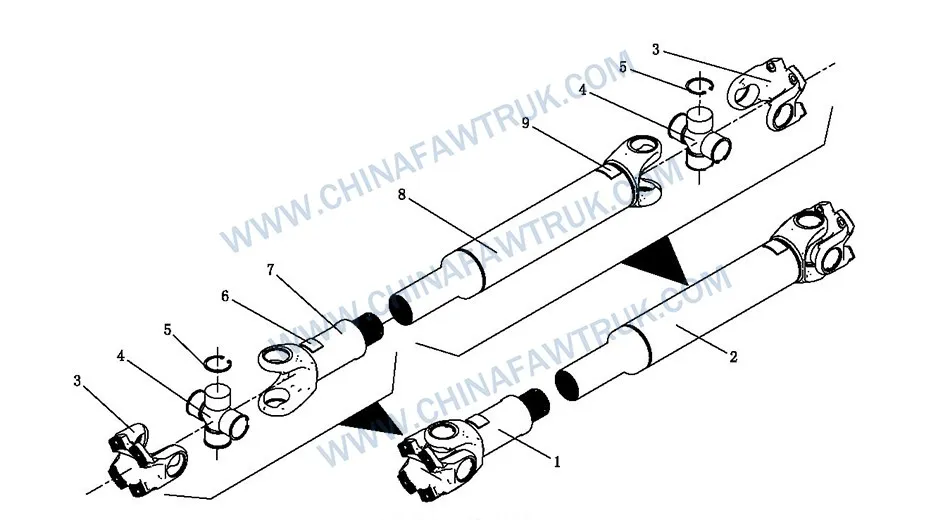

FAW Russian Central-Bridge Drive Shaft Assembly

System Core: The 55R Arctic Specification

The complete unit is identified as the Middle Axle Driveshaft and Universal Joint Assembly (Part No. 2205010-55R). The suffix “55R” is a critical identifier for the FAW Russian Central-Bridge Drive Shaft. It denotes a specific metallurgical and sealing standard designed for the Russian Federation. Standard driveshafts often utilize rubber boots and grease seals that become brittle and crack when exposed to temperatures below -30°C. The 55R specification ensures that all elastomeric components retain their flexibility in the deep freeze, preventing the ingress of abrasive silica dust common in mining environments.

This assembly serves as the primary link in the tandem drive system. It connects the output of the transfer case to the input of the middle axle’s through-shaft. Because the middle axle is mounted on a suspension system that allows for significant vertical travel, the FAW Russian Central-Bridge Drive Shaft must accommodate constantly changing operating angles. This requires a robust universal joint design capable of operating efficiently at high angles without generating non-uniform velocity vibrations, which would otherwise destroy the pinion bearings.

The structural integrity of the assembly is centered around the Middle Axle Driveshaft and Universal Joint Sub-assembly (Part No. 2205060-55R). This sub-assembly includes the main tube and the fixed yokes. The welding process used to join the yokes to the tube is friction welding, a method that ensures a homogeneous bond across the entire cross-section of the tube. This is vital for the FAW Russian Central-Bridge Drive Shaft, as it must transmit torque spikes that can exceed 25,000 Nm when the differential locks are engaged in low range.

Articulation Logic: Cross Shafts and Bearings

The articulation capability of the FAW Russian Central-Bridge Drive Shaft is provided by the Cross Shaft and Needle Roller Bearing Assembly (Part No. 2205030B761). There are two of these assemblies, one at each end of the shaft. The cross shaft, or spider, is forged from case-hardened alloy steel to resist the immense crushing loads applied by the needle bearings during torque transmission. The trunnions are ground to micron-level tolerances to ensure a perfect fit with the bearing cups.

Connecting the cross shaft to the transfer case and axle is the Flange Yoke (Part No. 2205023B761). This flange features a serrated face (often Hirth coupling style or simply high-friction face) to mate securely with the output flanges. The bolt holes are precision-drilled to ensure perfect concentricity. Any runout in the flange yoke would translate into severe vibration at highway speeds. The FAW Russian Central-Bridge Drive Shaft relies on the rigidity of this yoke to maintain alignment under load.

Retention of the bearing cups is managed by a series of Snap Rings (Part Nos. 2205041-A0M through 2205048-A0M). These rings are available in graduated thicknesses. During the assembly process, technicians select the specific ring thickness that centers the cross shaft perfectly within the yoke. This “selective fit” is crucial for the FAW Russian Central-Bridge Drive Shaft. If the cross shaft is off-center, it creates a rotating imbalance that cannot be corrected by external weights, leading to premature failure of the universal joint.

Extension Logic: Spline Yokes and Tubes

To accommodate the changes in length between the transfer case and the axle as the suspension moves, the FAW Russian Central-Bridge Drive Shaft features a telescoping slip joint. This is comprised of the Spline Shaft Yoke and Universal Joint Assembly (Part No. 2205050-55R) sliding into the Spline Shaft Yoke Assembly (Part No. 2205020-55R). The internal splines are coated with a low-friction Glidecoat or Rilsan material. This coating reduces the thrust load required to change the shaft length while under torque.

Without this low-friction coating, the metal-on-metal splines would “lock” under heavy acceleration, transmitting suspension shocks directly into the transfer case bearings. The FAW Russian Central-Bridge Drive Shaft design prevents this, allowing for smooth plunging action even when transmitting maximum engine power. The seal protecting this spline is a multi-lip design engineered to scrape ice and dried mud off the shaft as it retracts, preventing contamination of the internal grease.

The main body is the Middle Axle Driveshaft Tube, Welded Yoke and Spline Sleeve Assembly (Part No. 2205015-55R). This tube determines the critical speed of the shaft. For the long wheelbase of the CA3250P66K24L1TE5Z, the tube diameter and wall thickness are calculated to ensure the natural resonant frequency (whirl speed) is well above the truck’s maximum RPM. This prevents the FAW Russian Central-Bridge Drive Shaft from bowing or whipping at high speeds, a common cause of catastrophic driveline failure.

Balancing Logic: Precision Weights

Every FAW Russian Central-Bridge Drive Shaft undergoes a stringent dynamic balancing procedure before leaving the factory. Because the mass of the cast yokes and the welded tube is never perfectly distributed, centrifugal force would cause violent vibration without correction. To counteract this, Balance Sheets (Part Nos. 2205081-A0M through 2205089-A0M and 2205071-A0M through 2205079-A0M) are spot-welded to the tube ends.

The parts catalog lists a wide variety of these weights, differing in mass by mere grams. This granularity allows the balancing machine to achieve a near-perfect neutral balance. In the FAW Russian Central-Bridge Drive Shaft, these weights are welded securely to withstand the centrifugal forces at 2,500 RPM and the shock of stones hitting the shaft. Losing a weight results in immediate and noticeable vibration.

The placement of these weights is calculated to correct both static imbalance (heavy spot) and couple imbalance (wobble). By ensuring the FAW Russian Central-Bridge Drive Shaft spins true, FAW minimizes stress on the pinion seals and transfer case output bearings, significantly extending the service life of the entire drivetrain components connected to it.

Component Breakdown: 126. Middle Axle Drive Shaft

| No. |

Part Number |

Part Name |

Qty |

| – | 2205010-55R | Middle Axle Driveshaft and Universal Joint Assembly | 1 |

| 1 | 2205050-55R | Spline Shaft Yoke and Universal Joint Assembly | 1 |

| 2 | 2205060-55R | Middle Axle Driveshaft and Universal Joint Sub-assembly | 1 |

| 3 | 2205023B761 | Flange Yoke | 2 |

| 4 | 2205030B761 | Cross Shaft and Needle Roller Bearing Assembly | 2 |

| 5 | 2205041-A0M | Snap Ring (Various Thicknesses) | 8 |

| 6 | 2205081-A0M | Balance Sheet (Various Weights) | As Req |

| 7 | 2205020-55R | Spline Shaft Yoke Assembly | 1 |

| 8 | 2205015-55R | Middle Axle Driveshaft Tube, Welded Yoke and Spline Sleeve Assembly | 1 |

| 9 | 2205071-A0M | Balance Sheet (Various Weights) | As Req |

Conclusion: The Kinetic Bridge

The FAW Russian Central-Bridge Drive Shaft is a masterpiece of kinetic engineering, designed to bridge the gap between static power and dynamic motion. Its robust construction, characterized by the “55R” Arctic specification, ensures that the vehicle maintains traction and drivability in conditions that would immobilize lesser trucks. Every component, from the precision-machined slip yokes to the carefully selected balance weights, plays a vital role in this performance.

For operators of the CA3250P66K24L1TE5Z, the FAW Russian Central-Bridge Drive Shaft represents reliability. Regular maintenance—specifically greasing the U-joints and checking for spline play—is the only requirement to keep this component functioning for the life of the vehicle. By using genuine replacement parts that match the original metallurgical specifications, fleet managers can ensure that their trucks remain the backbone of their heavy-haul operations.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.