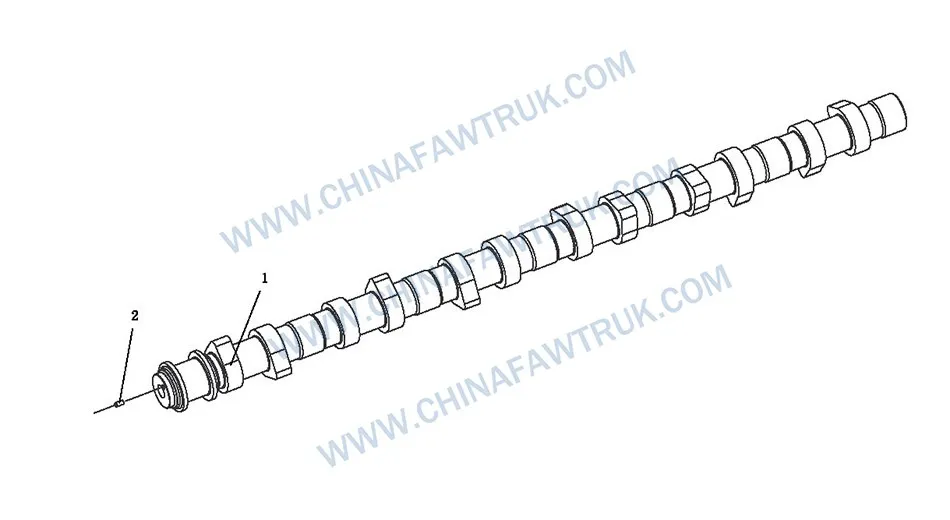

FAW Russian Camshaft Logic Assembly: 2 Vital Components for Unbeatable Valve Timing Precision

The FAW Russian Camshaft Logic Assembly acts as the central nervous system for the CA3250P66K24L1TE5Z engine, orchestrating the precise timing of air intake and exhaust. Engineered to resist extreme torsional stress and sub-zero friction, this assembly ensures the engine breathes efficiently in the Russian winter. This guide explores the metallurgy and geometric precision that make this system fail-safe.

FAW Russian Camshaft Logic Assembly

The Camshaft: Defining Engine Character and Durability

The dominant component of this system is the Camshaft (Part No. 1006016-81D). In the specific context of the FAW Russian Camshaft Logic Assembly, this shaft is not merely a rotating steel bar; it is a high-precision function generator. The profile of each cam lobe dictates the duration and lift of the valves, directly influencing the engine’s torque curve and cold-start capability.

For the Russian market, the material specification of the FAW Russian Camshaft Logic Assembly is upgraded to a chilled cast iron or forged steel alloy. This material selection is critical to combat the lack of lubrication during Arctic startups. When the engine oil is thick and sluggish at -40°C, the cam lobes experience boundary lubrication conditions, where metal-to-metal contact with the rocker arm rollers is highly probable.

To survive this, the lobes of the FAW Russian Camshaft Logic Assembly undergo induction hardening. This process creates a wear-resistant “skin” on the friction surfaces while leaving the core of the shaft ductile. This ductility is essential; a shaft that is brittle through-and-through would snap under the torsional shock loads of a diesel engine’s firing pulses, especially when driving the high-pressure fuel pump.

The surface finish of the bearing journals on the FAW Russian Camshaft Logic Assembly is polished to a mirror-like Ra value. This ultra-smooth finish helps maintain the hydrodynamic oil wedge required to float the shaft within the cylinder head bearings. Any imperfection here would act as a cutting tool, destroying the soft babbitt bearing material and leading to a catastrophic loss of oil pressure in the upper engine.

The Cylindrical Pin: The Anchor of Timing Accuracy

While physically small, the Cylindrical Pin (Part No. Q5210614) is the mechanical anchor of the FAW Russian Camshaft Logic Assembly. Its primary function is to lock the camshaft timing gear to the shaft itself. In high-torque diesel applications, the resistance from the valve springs creates a significant counter-torque that tries to spin the gear independently of the shaft.

The engineering tolerance of this pin within the FAW Russian Camshaft Logic Assembly is measured in microns. It must be an interference fit. If there is any “slop” or play, the repetitive hammering of the engine’s power strokes will cause the pin to shear. A sheared pin results in immediate desynchronization of the valves and pistons, often leading to valves striking the piston crowns and destroying the engine.

Material science plays a huge role here. The pin used in the FAW Russian Camshaft Logic Assembly is manufactured from high-tensile, heat-treated steel. Standard steel pins become brittle in the extreme cold of the Russian Federation. A brittle pin could shatter under the shock load of a cold start, rendering the vehicle immobile in life-threatening temperatures.

During maintenance involving the FAW Russian Camshaft Logic Assembly, this pin is considered a single-use item. The stress of installation and years of operational shear load fatigue the metal. Reusing an old pin during a rebuild is a critical error that compromises the reliability of the entire valvetrain system.

Manufacturing Precision: Ensuring Geometric Perfection

The production of the FAW Russian Camshaft Logic Assembly involves rigorous quality control steps. The straightness of the shaft is paramount. Even a slight “runout” or bend in the shaft will cause it to bind in the bearing journals. In the cold, where clearances are tighter due to thermal contraction, a bent shaft will seize instantly upon cranking.

FAW employs automated laser scanning to verify the lobe indexing of the FAW Russian Camshaft Logic Assembly. Every cam lobe must be positioned at the exact degree relative to the keyway. If a lobe is ground just one degree off, the engine’s breathing efficiency drops, leading to incomplete combustion, black smoke, and reduced power output—unacceptable for a heavy-duty dump truck carrying full loads.

The heat treatment depth on the FAW Russian Camshaft Logic Assembly is also validated via ultrasonic testing. If the hardened layer is too thin, it will wear through rapidly, exposing the soft core metal. If it is too deep, the lobe becomes brittle. Achieving this balance is what differentiates a genuine FAW part from a cheap aftermarket copy that fails prematurely.

Arctic Operation: The Challenge of Thermal Contraction

Operating the FAW Russian Camshaft Logic Assembly in Siberia presents unique thermal challenges. Steel and cast iron contract at different rates. As the aluminum cylinder head (if equipped) or cast iron head cools down to -50°C, the clearance between the camshaft journals and the bearings changes.

The design of the FAW Russian Camshaft Logic Assembly accounts for this by specifying larger cold clearances. This ensures that the shaft can still rotate freely even when the engine block has physically shrunk around it. Using a camshaft with standard “temperate zone” tolerances in these conditions can lead to binding and starter motor failure.

Furthermore, the ramp angle of the cam lobes on the FAW Russian Camshaft Logic Assembly is designed to minimize valve slam. In extreme cold, valve springs can become sluggish. An aggressive cam profile could cause the lifter to lose contact with the lobe (“valve float”), damaging the valvetrain. The FAW profile ensures positive contact is maintained at all temperatures.

Component Breakdown List

The following table details the core components of the FAW Russian Camshaft Logic Assembly. While simple in part count, these two items are the foundation of the engine’s mechanical timing.

| No. |

Part Number |

Part Name |

Qty |

| 1 |

1006016-81D |

Camshaft |

1 |

| 2 |

Q5210614 |

Cylindrical Pin |

1 |

Inspection Protocols for Long Life

Inspecting the FAW Russian Camshaft Logic Assembly requires precise measurement tools. The first step is to check the lobe lift using a micrometer. If the lobe height has worn down beyond the service limit, the valves will not open fully, strangling the engine’s air supply. This wear is often accelerated by the use of inferior engine oils that lack the necessary zinc additives for flat-tappet protection.

Visual inspection of the lobes on the FAW Russian Camshaft Logic Assembly is also crucial. Look for pitting, scoring, or discoloration (blueing) which indicates overheating due to oil starvation. If any lobe shows these signs, the entire shaft must be replaced, along with the mating followers or rockers. Polishing a damaged lobe is a temporary fix that will fail rapidly.

Always verify the condition of the Cylindrical Pin hole in the end of the shaft. If the hole has become oval-shaped or elongated, the timing gear will have excessive backlash. This results in erratic timing and a noisy valvetrain. In such cases, the FAW Russian Camshaft Logic Assembly is compromised, and the shaft must be scrapped, as the timing accuracy can no longer be guaranteed.

Conclusion: The Pulse of the Engine

The FAW Russian Camshaft Logic Assembly is a deceptive component; it appears simple but dictates the complex personality of the engine. From the hardened steel of the lobes to the shear strength of the locating pin, every aspect is engineered to provide reliable timing in the harshest environments on earth.

Substituting this critical assembly with a generic part risks the entire investment in the vehicle. Only genuine FAW parts possess the specific metallurgy required to resist the wear and thermal stress of Russian operations. By maintaining the integrity of the FAW Russian Camshaft Logic Assembly, fleet owners ensure their trucks deliver peak power and fuel efficiency for the long haul.

Packaging and Logistics

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.