Welcome to this expert technical analysis of the FAW Rear Axle Differential Assembly (Part No. 2403010QA6T), the “logic” core of the entire rear axle system for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This is the assembly that allows the truck to turn corners while delivering power.

The FAW Rear Axle Differential Assembly, also known as the “differential carrier,” is a complex set of gears. It is responsible for receiving power from the driveshaft via the main “ring gear” and then splitting that power between the two “half-shafts” (axles) that go to the wheels.

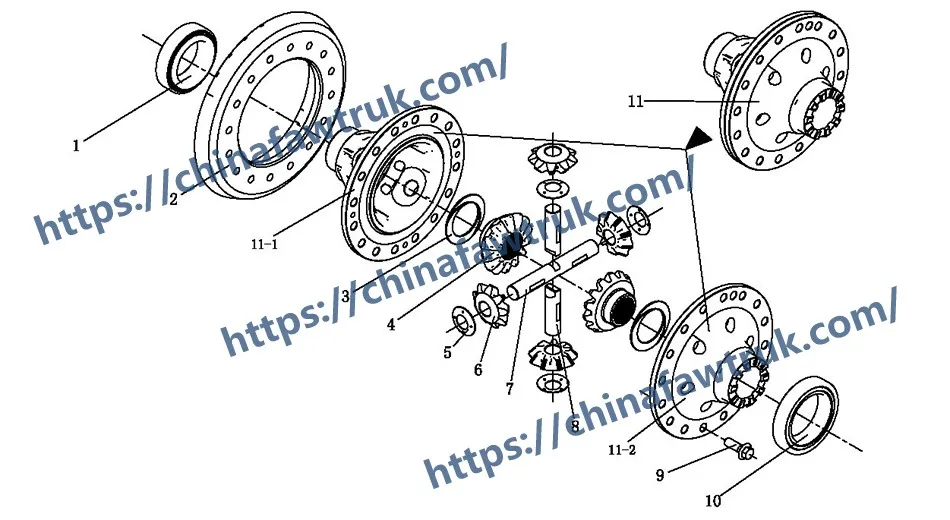

This in-depth guide is a critical resource for professional driveline technicians and parts specialists. We will deconstruct the entire FAW Rear Axle Differential Assembly into its 11 serviceable components, including the main ‘Ring Gear’ (2402037EA6T), the ‘Differential Case’ (2403015FA6T), the spider gears, the side gears, and the critical bearings.

The heart of the FAW Rear Axle Differential Assembly is the ‘Rear axle differential case assembly’ (2403015FA6T). This is the heavy-duty cast iron “carrier” that houses the “logic” gears. This assembly is so precise that it is listed in two halves:

These two halves are machined as a matched set and are not interchangeable. They are bolted together to form a spherical “cage” that holds the spider gears. The ‘Rear axle driven bevel gear’ (the ring gear) is then bolted to the outside of this case. When the driveshaft spins the ring gear, it is *this case* that is the primary driven component. The entire FAW Rear Axle Differential Assembly spins as one unit.

The “differential logic” of the FAW Rear Axle Differential Assembly is achieved by the set of gears *inside* the case. These are:

This is how they work: The ‘Planetary gears’ (spider gears) are mounted on shafts (‘Long’ 2403061-A6T and ‘Short’ 2403062-A6T) inside the differential case. The ‘Half-shaft gears’ (side gears) are splined to the axle shafts (half-shafts) and mesh with these spider gears.

When the truck drives straight, the entire FAW Rear Axle Differential Assembly (case, spider gears, and side gears) spins as one solid unit. However, when the truck turns a corner, the *outer* wheel must spin faster than the *inner* wheel. The differential allows this to happen: the ‘Planetary gears’ begin to “walk” or “orbit” around the ‘Half-shaft gears’, allowing the outer wheel (and its side gear) to spin faster, while the inner wheel (and its side gear) spins slower.

This “differentiation” of wheel speeds is the core logic of the FAW Rear Axle Differential Assembly, and it prevents the tires from “scuffing” and the axles from binding during a turn. These gears are separated by ‘Planetary gear gaskets’ (2403058-A9T) and ‘Half-shaft gear gaskets’ (2403053D1H), which are critical “thrust washers” that handle the immense forces between the gears.

The “reduction” part of the FAW Rear Axle Differential Assembly is the ‘Rear axle driven bevel gear’ (2402037EA6T), also known as the “ring gear.” This is the large-diameter gear that is bolted to the differential case.

Its part number corresponds to the ‘Rear axle reduction gearbox assembly (io=2.867)’ (2403010QA6T). This “io=2.867” is the gear ratio. It means the driveshaft (and its pinion gear) must spin 2.867 times to make this ring gear (and the wheels) spin *once*. This is the final torque multiplication in the entire truck, providing the immense power needed to move a heavy load.

The entire FAW Rear Axle Differential Assembly (with the ring gear attached) spins within the axle housing on two massive bearings. These are the ‘Tapered roller bearing assembly’ (2403060-A8T-C00) and ‘Tapered roller bearing assembly’ (2403070-A6T-C00). These bearings are critical, as they must support the full weight of the differential, the torque from the driveshaft, and the entire weight of the truck.

The parts list for the FAW Rear Axle Differential Assembly details the ‘Hex flange bolt, coarse rod (Standard Type)’ (Q1851845TF2KS). This is a critical fastener. These bolts are used to bolt the ‘Rear axle driven bevel gear’ (the ring gear) to the ‘Rear axle differential case assembly’ (the carrier).

There are typically 10 or 12 of these high-tensile, “T” suffixed bolts (though the quantity is cut off in the image). These bolts must handle 100% of the final drive torque. They are “shear” fasteners, as the torque from the ring gear tries to shear them off the case.

These are always “torque-to-yield” or single-use bolts. They must be replaced every time they are loosened and must be tightened in a specific “star” pattern with a torque wrench to ensure the ring gear is perfectly flat and “true” on its mount. A loose bolt here will shear, destroying the ring gear and the entire FAW Rear Axle Differential Assembly. The integrity of the FAW Rear Axle Differential Assembly is completely dependent on these fasteners.

The following table provides the complete, detailed breakdown of all 11 primary components identified in the ‘Rear Axle Differential Assembly’ diagram for the FAW CA4251P66K24T1A3E5 tractor. This FAW Rear Axle Differential Assembly is a precision-matched set.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 2403010QA6T | Rear axle differential assembly (io=2.867) | 1 |

| 2 | 2403060-A8T-C00 | Tapered roller bearing assembly | 1 |

| 3 | 2402037EA6T | Rear axle driven bevel gear | 1 |

| 4 | 2403053D1H | Gasket-half-shaft gear | 2 |

| 5 | 2403051D1HB1 | Half-shaft gear | 2 |

| 6 | 2403058-A9T | Planetary gear gasket | 4 |

| 7 | 2403056D1H | Planetary gear | 4 |

| 8 | 2403061-A6T | Long planetary gear shaft | 1 |

| 9 | 2403062-A6T | Short planetary gear shaft | 2 |

| 10 | Q1851845TF2KS | Hex flange bolt, coarse rod (Standard Type) | |

| 10 | 2403070-A6T-C00 | Tapered roller bearing assembly | 1 |

| 11 | 2403015FA6T | Rear axle differential case assembly | 1 |

| 11-1 | 2403018FA6T | Rear axle differential right case | 1 |

| 11-2 | 2403017FA6T | Rear axle differential left case | 1 |

The specifications for the FAW Rear Axle Differential Assembly are defined by its function as a high-torque, final-drive reduction gearset with an integrated differential. The FAW Rear Axle Differential Assembly is the “logic” core of the axle.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Rear Axle Differential Assembly |

| Main Assembly P/N | 2403010QA6T |

| Gear Ratio (io) | 2.867 |

| System Type | Final Drive Differential Carrier |

| Main Driven Gear | 1x ‘Rear axle driven bevel gear’ (2402037EA6T) |

| Differential Case | 1x ‘Rear axle differential case assembly’ (2403015FA6T) |

| Internal Gears | 4x Planetary (‘Spider’) Gears, 2x Half-Shaft (‘Side’) Gears |

| Main Carrier Bearings | 2x Tapered Roller Bearing Assemblies (2403060-A8T-C00, 2403070-A6T-C00) |

| Primary Function | To provide final gear reduction (torque multiplication) and allow for different wheel speeds during turns. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.