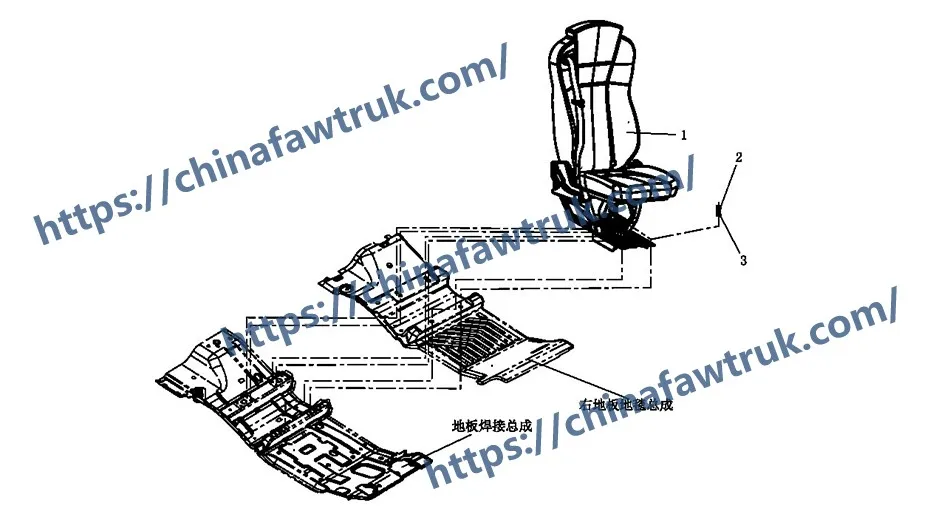

Welcome to this critical safety and ergonomic breakdown of the FAW Front Seat Assembly (Assembly 696). This is the complete, 3-component-type, passenger-side (or “co-driver”) seat for the FAW Jiefang CA4251P66K24T1A3E5 6×4 diesel semi-trailer tractor. This component’s “logic” is entirely focused on safety, durability, and long-haul comfort for the second driver or passenger.

Unlike the ‘Driver Seat Assembly’ (Assembly 695), which is a complex “air-ride” system, the FAW Front Seat Assembly (6900010-D04-C00) is a robust, mechanically-adjusting seat. Its “logic” is to provide a structural, load-bearing anchor point for the passenger that is fully integrated into the cab’s “safety cell.” This includes a reinforced steel frame, integrated seatbelt anchor points, and a high-density foam structure.

This in-depth guide is an essential resource for cab technicians, fleet safety managers, and parts specialists. We will deconstruct the entire FAW Front Seat Assembly into its 3 distinct serviceable component types. We will analyze the “structural & safety logic” of the main ‘Front seat assy’ itself, and the critical “anti-vibration” logic of the 12-piece (6 bolts, 6 washers) fastener system that secures this safety device to the cab floor.

The ‘Front seat assy’ (6900010-D04-C00) is the primary component and the main serviceable part. It is a complete, “all-in-one” assembly. Its “logic” is a blend of structural safety and ergonomic comfort.

1. The “Structural & Safety” Logic:

This is the “logic” of survival. The FAW Front Seat Assembly is a primary safety device. The foundation is a heavy-gauge, welded steel frame. This “skeleton” is the load-bearing structure.

Critically, this frame includes the **integrated seatbelt anchor points**. These are not just drill-holes; they are reinforced, hardened steel plates designed to withstand the thousands of pounds of “shear” and “tensile” force generated in a collision. This “logic” ensures the seatbelt remains anchored to the frame, protecting the passenger.

The frame also includes the integrated headrest, which has an “anti-whiplash” logic, and a rigid backrest designed to prevent “submarining” (sliding under the lap belt) in a frontal impact.

2. The “Ergonomic & Mechanical” Logic:

This is the “comfort” logic. The FAW Front Seat Assembly provides two key mechanical adjustments:

3. The “Durability & Material” Logic:

The “soft” parts of the FAW Front Seat Assembly are engineered for commercial-grade durability. The “logic” is to use materials that can withstand 10+ hours of use per day.

High-Density Foam: The cushioning is a “high-density” (high kg/m³) polyurethane foam. Unlike soft car-seat foam, this “logic” provides firm, orthopedic support, preventing the “bottoming-out” and “packing-down” that leads to driver fatigue and back pain.

Heavy-Duty Upholstery: The cover is a “truck-grade” textile or vinyl. Its “logic” is to be highly resistant to abrasion (from sliding in/out), UV-resistant (to prevent fading and cracking), and chemical-resistant (for easy cleanup of spills).

This group of 12 components is the “safety-critical” fastening system for the FAW Front Seat Assembly. Its “logic” is to create a 6-point, vibration-proof mount that *cannot* fail.

The system consists of six (6) ‘Inner hexagon cylindrical head screws’ (CQ2180820F6) and six (6) ‘Spring washers’ (Q40308F6).

Component 2: ‘Inner hexagon… screw’ (CQ2180820F6): This is the bolt. The “logic” of choosing an “inner hexagon” (Allen head) is for high-torque application. It allows a technician to apply a very high, precise clamping force without the tool “slipping.” The “cylindrical head” logic allows the bolt to sit flush or recessed within the seat rail, preventing it from snagging cargo or clothing.

Component 3: ‘Spring washer’ (Q40308F6): This is the “anti-vibration” logic. A “spring washer” (or “split washer”) is a hardened steel ring that has been split and twisted. When the bolt (Component 2) is tightened, this washer is flattened.

This “flattening” creates two “logic” functions: 1) It provides “spring tension,” constantly pushing back against the bolt head, preventing it from loosening. 2) Its sharp, cut edges “bite” into both the bolt head and the seat rail. This “biting” logic makes it physically impossible for the bolt to vibrate loose from road shock.

The “service logic” for the FAW Front Seat Assembly is based on replacing the main unit and its critical fasteners.

Seat Failure: The main ‘Front seat assy’ (6900010-D04-C00) is the primary serviceable part. It is not designed to be “re-foamed” or “re-upholstered” in the field. The “logic” is that if the seat has a structural failure (a cracked frame, a failed recliner), or a comfort failure (collapsed foam, torn upholstery), the entire unit is replaced.

Fastener Failure (Critical Safety): The fasteners (Components 2 & 3) are also serviceable parts. The ‘Spring washer’ (Q40308F6) is a **single-use component**. The “logic” is that once it has been flattened, its “spring” tension is compromised. Re-using an old spring washer is a critical safety error that can lead to a loose seat.

The “service logic” for replacing a FAW Front Seat Assembly is to unbolt the 6 bolts, remove the old seat, place the new seat, and secure it with **6 new bolts (CQ2180820F6) and 6 new spring washers (Q40308F6)** to guarantee a safe, factory-spec, anti-vibration installation.

The following table provides the complete, detailed breakdown of all 3 component types identified in the FAW Front Seat Assembly diagram for the FAW CA4251P66K24T1A3E5 tractor.

| Mark | Part No. | Part Name | Quantity |

|---|---|---|---|

| 1 | 6900010-D04-C00 | Front seat assy | 1 |

| 2 | CQ2180820F6 | Inner hexagon cylindrical head screw | 6 |

| 3 | Q40308F6 | Spring washer | 6 |

The specifications for the FAW Front Seat Assembly are defined by its function as a structural, ergonomic, and safety-critical component for the passenger.

| Vehicle Application | FAW Jiefang CA4251P66K24T1A3E5 6×4 Tractor |

| Component Group | FAW Front Seat Assembly (Passenger) |

| System Type | Static / Mechanical Adjusting Seat |

| Primary Logic | Structural Safety (Steel Frame, Seatbelt Anchor) |

| Secondary Logic | Ergonomic Comfort (Foam, Adjustments), Durability |

| Component 1 (Seat) | ‘Front seat assy’ (6900010-D04-C00) |

| Component 2 (Bolt) | ‘Inner hexagon… screw’ (CQ2180820F6) – Qty 6 |

| Component 3 (Washer) | ‘Spring washer’ (Q40308F6) – Qty 6 |

| Fastener Logic | 6-Point Mount, High-Torque, Anti-Vibration (Spring Washer) |

| Serviceability | Seat (Component 1) is a single MSU. Washers (Component 3) are **Single-Use**. |

FAW parts, including the Cylinder Block Assembly, are packaged with care to ensure safe delivery. Each component is secured in protective materials to prevent damage during transit. The logistics network guarantees timely shipments worldwide, supporting efficient maintenance operations. Below is an image illustrating the standard packaging for FAW truck parts, showcasing the attention to detail in handling and storage.

This packaging approach minimizes the risk of corrosion or impact damage, ensuring that parts like the FAW Cylinder Block Assembly arrive in perfect condition. Customers can rely on FAW’s logistics for consistent quality and reliability.