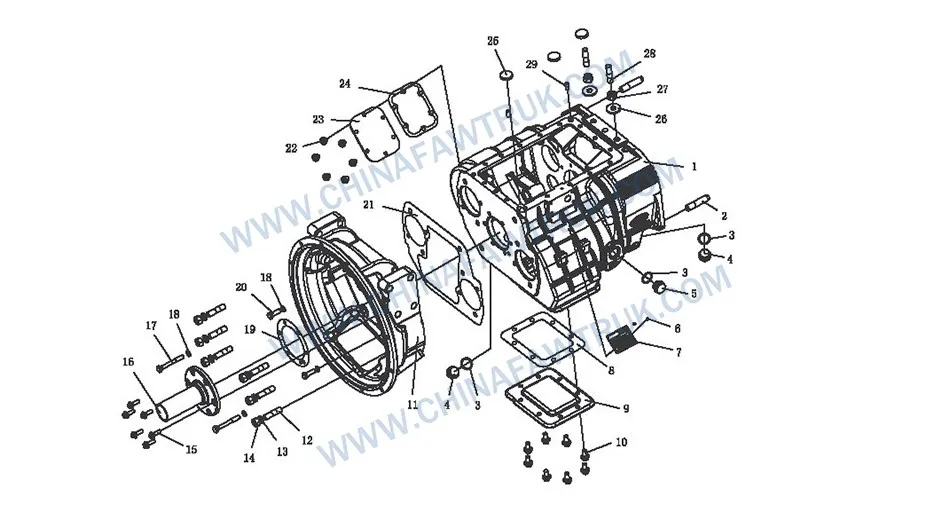

Carcasa principal de transmisión rusa FAW: Masterización 29 Componentes críticos para una integridad inquebrantable del tren motriz

El Carcasa principal de transmisión rusa FAW assembly serves as the skeletal backbone of the CA3250P66K24L1TE5Z dump truck’s propulsion system. Engineered to contain the immense torque forces of the gearbox while surviving the brutal thermal shocks of the Siberian winter, this casing logic is the foundation of driveline reliability. Esta guía analiza la 29 componentes estratégicos, from the high-strength casting to the precision PTO interfaces, that define this heavy-duty assembly.

FAW Russian Transmission Main Housing Logic Assembly

Metallurgical Fortification: The Housing Core

El componente principal de la Carcasa principal de transmisión rusa FAW la asamblea es la Alojamiento de transmisión (Número de pieza. 1701031-BSX808). This massive casting is not merely a container for gears; it is a structural member that must resist the twisting torque of the driveshaft and the bending moments of the chassis. In the Russian Arctic context, the metallurgy of this housing is critical. Standard grey iron can become brittle at -40°C, leading to catastrophic stress fractures under heavy load. FAW utilizes a high-grade nodular graphite iron alloy for the Carcasa principal de transmisión rusa FAW, ensuring that the crystalline structure remains ductile and shock-absorbent even in the deepest freeze.

Integrated with the main case is the Clutch Housing Assembly (Número de pieza. 1601010-896). This bell housing acts as the adapter between the engine block and the transmission. The precision of the machining on the mating surfaces of the Carcasa principal de transmisión rusa FAW es primordial. Any deviation in planarity would lead to misalignment between the crankshaft and the transmission input shaft. Such misalignment causes severe vibration, destroying the clutch disc and the input shaft bearings. The robust design of these housings features external ribbing, which not only increases stiffness but also acts as a heat sink, dissipating the thermal energy generated by gear friction.

The assembly also includes specific locating hardware, como el Pin de localización – Auxiliary Case (Número de pieza. 1701052-A7G) y Pasador cilíndrico (Número de pieza. Q5221226). These pins take the shear loads off the mounting bolts and ensure perfect alignment during assembly. In the maintenance environment of a Russian mine, where heavy components are often manhandled into place, these pins prevent the Carcasa principal de transmisión rusa FAW from being installed slightly off-center, protecting the gear sets from premature wear.

Interface Dynamics: Toma de fuerza (PTO) Readiness

A defining feature of the dump truck application is the need for hydraulic power to lift the bed. El Carcasa principal de transmisión rusa FAW is engineered with multiple Power Take-Off (PTO) puertos. Estos incluyen el Placa de cubierta – Bottom PTO Hole (Número de pieza. 1701036-A7G) y el Placa de cubierta – Side PTO Hole (Número de pieza. 1701043-A7G). These access points allow for the installation of hydraulic pumps directly driven by the transmission countershaft.

Sealing these interfaces is a critical challenge in the Carcasa principal de transmisión rusa FAW sistema. The assembly utilizes specialized gaskets: Empaquetadora – Bottom PTO Hole (Número de pieza. 1701037-A7G) y Empaquetadora – Side PTO Hole (Número de pieza. 1701044-A7G). These gaskets must withstand the hot, thin transmission fluid during operation and resist shrinking during the cold soak of a Siberian night. A leak at these points would drain the transmission of lubricant, conduciendo a convulsiones. The FAW gaskets are composed of oil-resistant fiber composites that swell slightly upon contact with oil, creating a positive seal.

The covers are secured with high-torque Perno de brida hexagonal (Número de pieza. Q1841225S and Q1841020S). The flange design is essential for the Carcasa principal de transmisión rusa FAW PTO covers because it distributes the clamping load evenly, preventing the thin steel cover plates from warping between the bolt holes. This ensures a uniform compression of the gasket, maintaining a leak-free seal even under the intense vibration of PTO operation.

Lógica fluida: Drain Plugs and Magnetic Filtration

The longevity of the transmission gears depends entirely on clean lubrication. El Carcasa principal de transmisión rusa FAW incorporates a passive filtration system using Imán elements (Número de pieza. 1701033-A7G). Placed strategically within the housing or on the drain plugs, these magnets capture ferrous metal shavings generated by gear wear. In the heavy-load cycles of a dump truck, this metallic dust acts as a grinding paste. By trapping these particles, the magnets prevent them from circulating through the bearings, significantly extending the overhaul interval of the transmission.

Fluid maintenance is facilitated by the Oil Drain Plug Assembly (Número de pieza. 1701030-A4H) y el Plug Body (Número de pieza. 1701031-11). These plugs are engineered with tapered threads or integrated sealing washers to prevent leaks. En el Carcasa principal de transmisión rusa FAW, these plugs are positioned at the absolute lowest points of the casing to ensure complete drainage of old, contaminated oil during service.

El sistema también incluye el Transmission Nameplate (Número de pieza. 1701046-A7G), secured by Tornillo de cabeza plana empotrado en cruz (Número de pieza. Q214046). Aunque aparentemente menor, this plate carries vital information about gear ratios and oil specifications. In a mixed fleet environment, ensuring the correct viscosity gear oil is used (especially for Arctic operations) es crucial. The durability of this nameplate on the Carcasa principal de transmisión rusa FAW ensures that maintenance personnel always have access to critical data.

Dinámica de sujeción: Studs and Locking Nuts

La integridad estructural del Carcasa principal de transmisión rusa FAW is maintained by a complex array of fasteners. Key among them are the Perno de doble extremo (Número de pieza. 1701026-A7G and CQ1211645S). These studs are used for mounting heavy auxiliary components where aligning bolt holes would be difficult. Studs allow components to be hung in place before tightening, a crucial feature for field repairs.

Securing these studs are high-grade Tuerca hexagonal (Número de pieza. CQ34116T) y especializado Tipo 1 Non-metallic Insert Hex Lock Nut (Número de pieza. Q32916). The nylon-insert lock nuts are essential for the Carcasa principal de transmisión rusa FAW because they resist loosening under the severe vibration of the drivetrain. Unlike split washers which can flatten over time, the nylon insert creates a prevailing torque that holds the nut firm even if the clamping load fluctuates due to thermal expansion.

La seguridad adicional es proporcionada por Arandela de resorte (Número de pieza. Q40316 and Q40312) y Lavadora grande (Número de pieza. Q40216). The large washers are used to distribute load on aluminum components or over oversized holes, preventing the fastener from crushing the housing material. Every bolt and nut in the Carcasa principal de transmisión rusa FAW BOM is selected for its tensile strength and corrosion resistance, ensuring the assembly remains tight and leak-free for the life of the vehicle.

Desglose de componentes: 102. Transmission Main Housing Logic Assembly

| No. |

Número de pieza |

Nombre de la pieza |

Cantidad |

| 1 | 1701031-BSX808 | Alojamiento de transmisión | 1 |

| 2 | 1701052-A7G | Pin de localización – Auxiliary Case | 2 |

| 3 | 1701033-11 | Empaquetadora | 3 |

| 4 | 1701030-A4H | Oil Drain Plug Assembly | 2 |

| 5 | 1701031-11 | Plug Body | 1 |

| 6 | Q214046 | Tornillo de cabeza plana empotrado en cruz | 2 |

| 7 | 1701046-A7G | Transmission Nameplate | 1 |

| 8 | 1701037-A7G | Empaquetadora – Bottom PTO Hole | 1 |

| 9 | 1701036-A7G | Placa de cubierta – Bottom PTO Hole | 1 |

| 10 | Q1841225S | Perno de brida hexagonal Vástago grueso | 8 |

| 11 | 1601010-896 | Clutch Housing Assembly | 1 |

| 12 | 1701026-A7G | Perno de doble extremo | 6 |

| 13 | Q40316 | Arandela de resorte | 6 |

| 14 | CQ34116T | Tuerca hexagonal | 6 |

| 15 | Q1841030S | Perno de brida hexagonal Vástago grueso | 6 |

| 16 | 1701141-A7G | Cubrir – 1st Shaft Rear Bearing | 1 |

| 17 | CQ1501290TS | Perno de cabeza hexagonal | 2 |

| 18 | Q40312 | Arandela de resorte | 4 |

| 19 | 1701142-A7G | Empaquetadora – 1st Shaft Bearing Cover | 1 |

| 20 | CQ1501235TS | Perno de cabeza hexagonal | 2 |

| 21 | 1701022-A7G | Empaquetadora | 1 |

| 22 | Q1841020S | Perno de brida hexagonal Vástago grueso | 6 |

| 23 | 1701043-A7G | Placa de cubierta – Side PTO Hole | 1 |

| 24 | 1701044-A7G | Empaquetadora – Side PTO Hole | 1 |

| 25 | 1701033-A7G | Imán | 3 |

| 26 | Q40216 | Lavadora grande | 2 |

| 27 | Q32916 | Tipo 1 Non-metallic Insert Hex Lock Nut | 2 |

| 28 | CQ1211645S | Perno de doble extremo | 2 |

| 29 | Q5221226 | Pasador cilíndrico | 2 |

Conclusión: The Fortress of the Drivetrain

El Carcasa principal de transmisión rusa FAW assembly is more than a container; it is the fortress that protects the delicate gearsets of the CA3250P66K24L1TE5Z from the brutal reality of the outside world. By combining advanced metallurgical casting with precision sealing and robust fastening logic, FAW ensures that the transmission can deliver massive torque reliability, even in the unforgiving conditions of the Russian Arctic.

Para propietarios de flotas, maintaining this assembly means respecting the integrity of every component. Reusing a crushed PTO gasket or ignoring a missing magnetic plug can lead to leaks and internal contamination that destroy the gearbox. Al invertir en lo genuino Carcasa principal de transmisión rusa FAW componentes, Los operadores garantizan que sus camiones seguirán siendo los caballos de batalla confiables para los que fueron diseñados., delivering payloads and profits season after season.

Embalaje y Logística

piezas FAW, incluido el conjunto del bloque de cilindros, Se empaquetan con cuidado para garantizar una entrega segura.. Cada componente está asegurado con materiales protectores para evitar daños durante el transporte.. La red logística garantiza envíos puntuales en todo el mundo., apoyando operaciones de mantenimiento eficientes. A continuación se muestra una imagen que ilustra el embalaje estándar de las piezas de camiones FAW., mostrando la atención al detalle en el manejo y almacenamiento.

Este enfoque de embalaje minimiza el riesgo de corrosión o daños por impacto., asegurando que piezas como el conjunto de bloque de cilindros FAW lleguen en perfectas condiciones. Los clientes pueden confiar en la logística de FAW para obtener calidad y confiabilidad constantes.